Adapting artificial finger nail and its mfg. method

A technology of artificial fingernails and fingernails, applied in manicure or pedicure tools, applications, clothing, etc., which can solve problems such as complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

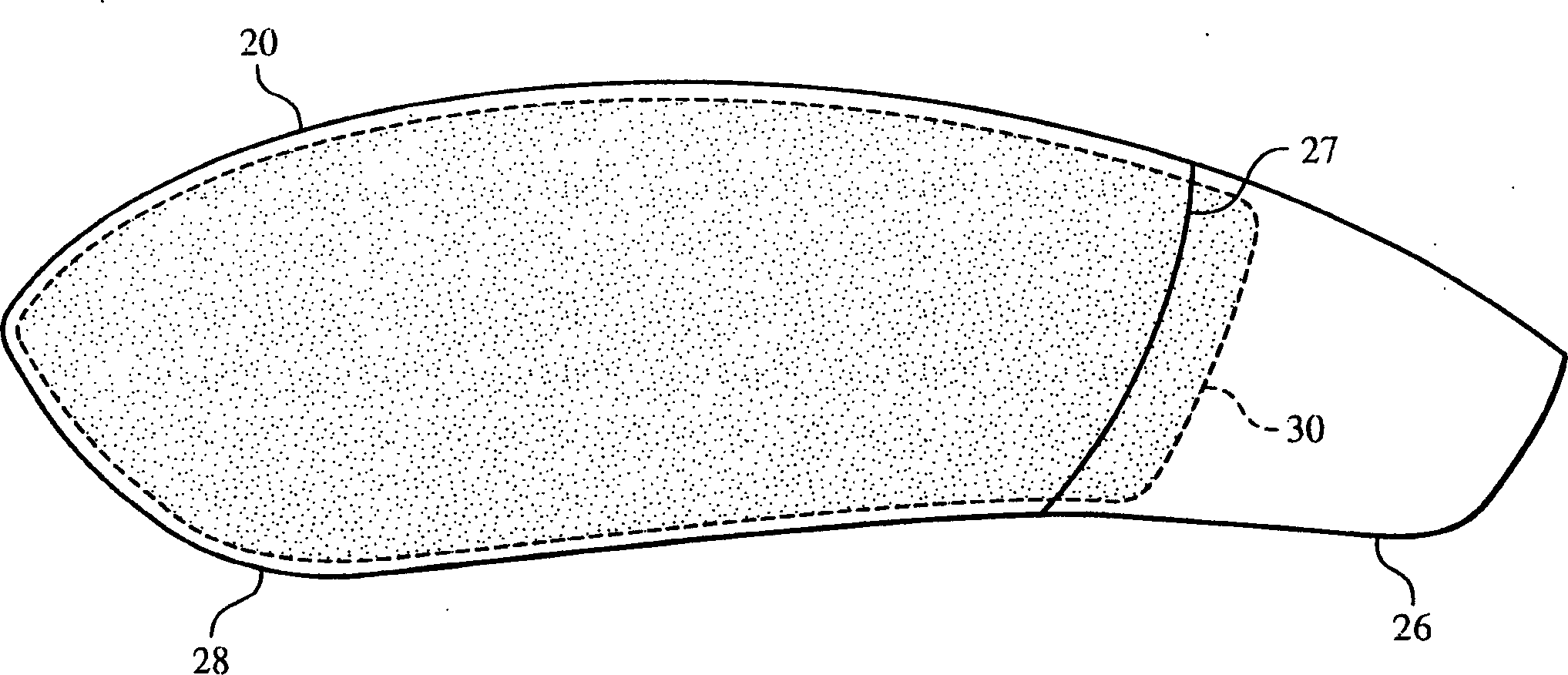

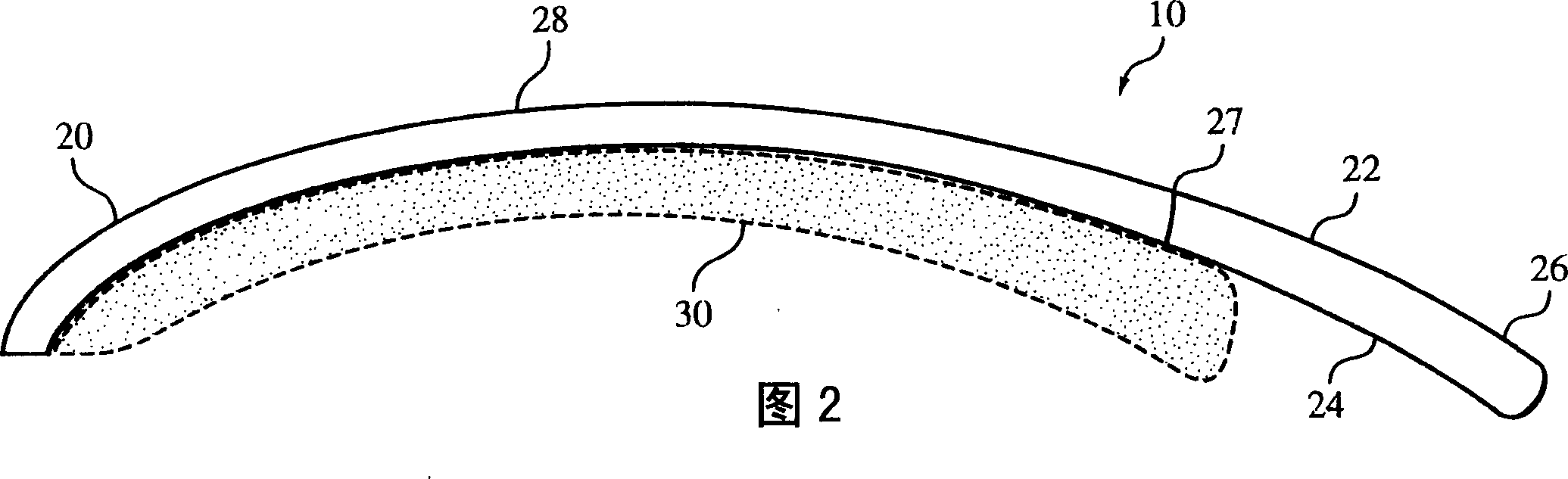

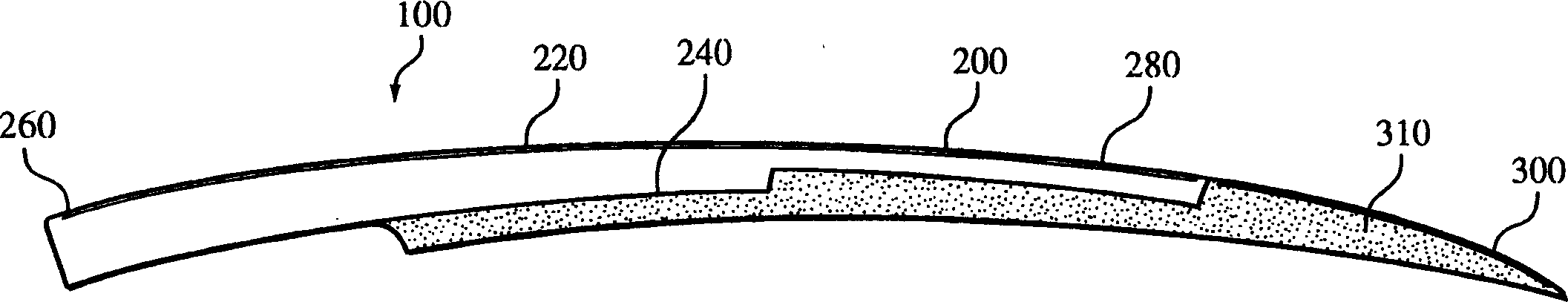

[0014] Now describing the accompanying drawings in detail, figure 1 and 2 show a preferred embodiment of an artificial fingernail adapted to accommodate different finger size and shape variations. The artificial fingernail 10 includes a polymer body 20 and a layer 30 of deformable material.

[0015] Polymer 20 has the general overall shape and structure of a natural fingernail, and has an upper surface 22 and a lower surface 24 . Polymer 20 may be a conventional plastic artificial fingernail, and is preferably made of a blend of acrylonitrile-butadiene-styrene (ABS) plastic and polycarbonate, but may also be formed by using conventional injection molding techniques known in the art. , made of any plastic-like material commonly used in artificial nail products such as ABS plastic, Nylon, Thonate Acetate, Vinyl Acetate, Polycarbonate, Polyvinyl Chloride, etc.

[0016] Polymer 20 has a forward distal portion 26 and a rear proximal portion 28, both of which may be transparent, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com