Tank with inner device convenient for filling

A convenient technology that can be used in fixtures, packaging, cans, etc., and can solve problems such as single, contaminated, and contaminated food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

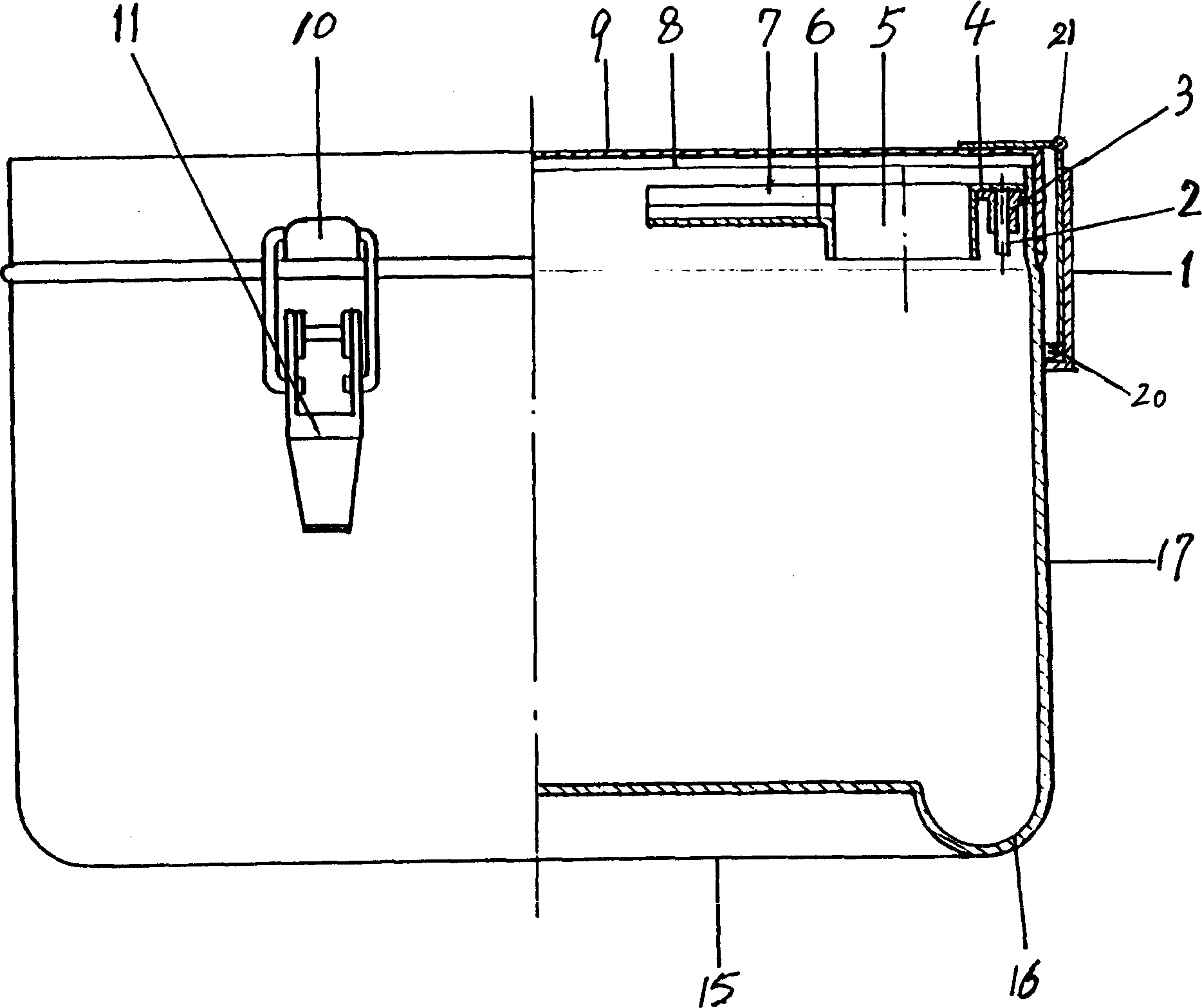

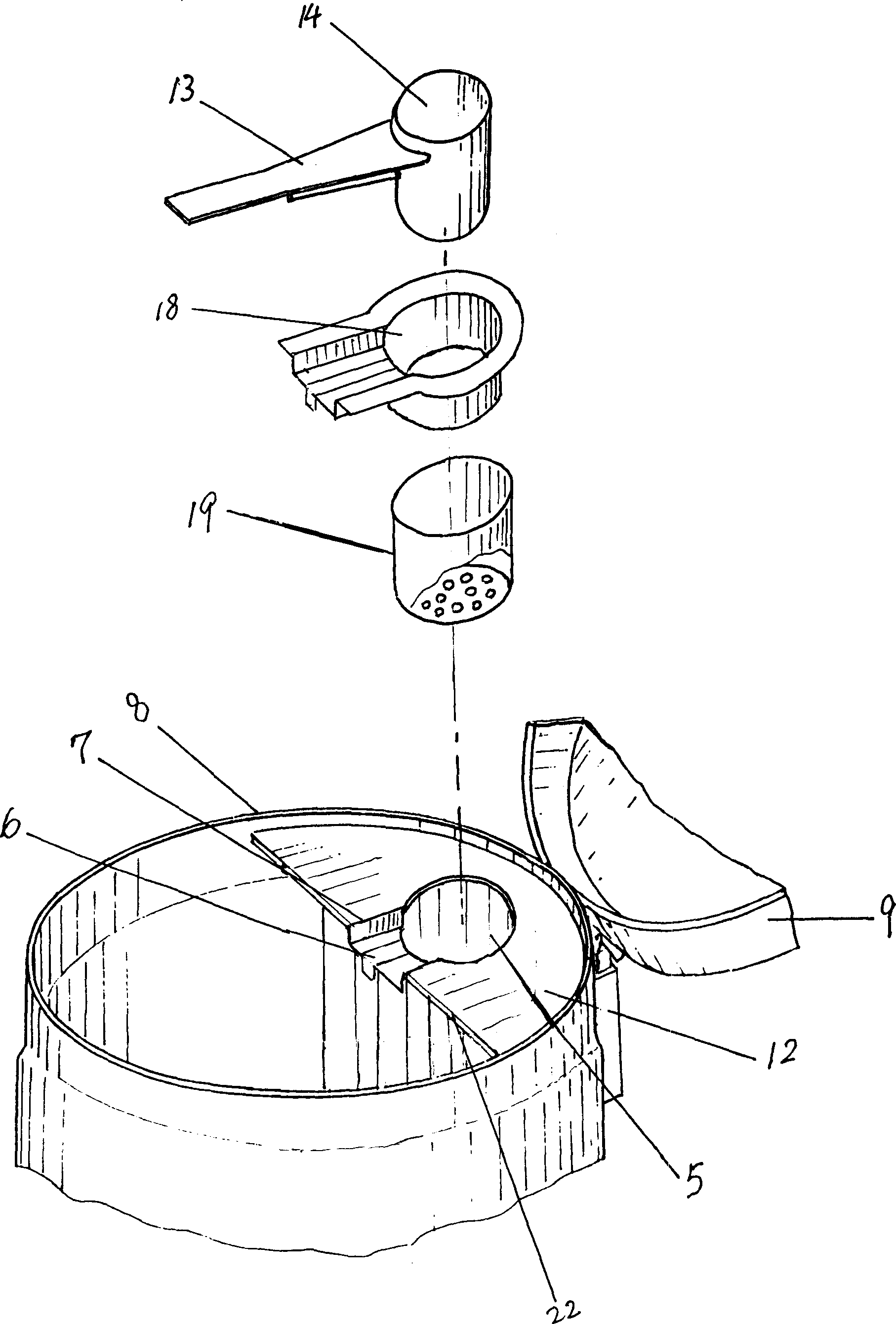

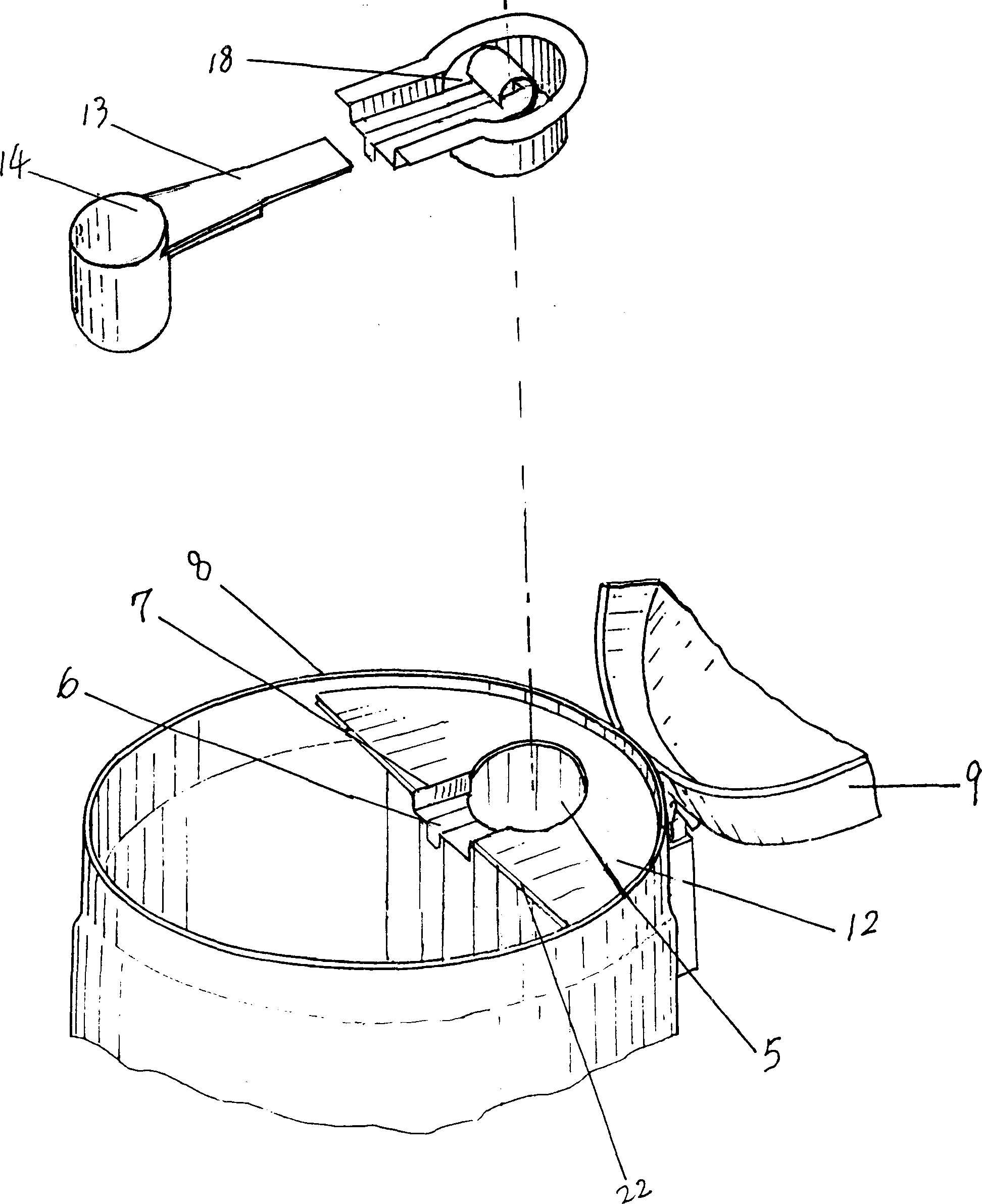

[0022] Example 1, such as figure 2 As shown, select a metal sheet of appropriate thickness to punch out a tank body and a tank cover with an arc groove 16 at the bottom, and design the upper pad mold according to the radian of the tank mouth so that the middle part of the upper pad after stamping is a concave hole 5, and then match it with a bridge and a concave hole The shape of the spoon is consistent with the mouth of the spoon. If there is a rib on the back of the spoon handle, a groove for supporting the rib should be left in the center of the bridge. Or use the welding method or stretching method to connect the arc edge of the upper pad to the inner wall of the tank near the edge of the tank mouth, and set a stopper in the arc groove opposite to the upper pad. Design spoon support 18 and miniature cup 19 by the diameter of recessed hole 5 in addition, can be inserted into recessed hole 5 after making miniature cup and spoon support bottom be connected as the criterion. ...

Embodiment 2

[0023] Example 2, such as Figure 4 As shown, select a metal sheet with an appropriate thickness. After stamping, there are 4 interspersed full holes on the lower pad, and the arc edge of the lower pad is squeezed or bonded to the inner wall of the tank near the edge of the tank mouth with special equipment, and stamped according to Example 1. For the upper pad, single rivet or bond four intersecting columns at the position corresponding to the full hole of the lower pad on the back of the upper pad, so that the lower pad supports the upper pad, and the rest is the same as in embodiment 1.

Embodiment 3

[0024] Example 3, such as Figure 5 As shown, the difference is that the insertion hole of the lower pad is a half hole, so that the insertion column with the end cap corresponding to the upper pad can be pushed into the hole to support the upper pad, and the rest is the same as in embodiment 1.

[0025] The manufacturing material of the present invention can be metal, glass, ceramics, plastic or their combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com