Sheet-form optical element package body, method of using sheet-form optical element, production method for sheet-form optical element package body, and production device for the same

A technology of optical components and assemblies, applied in the direction of optical components, optics, polarizing components, etc., can solve problems such as unsuitable for automation, difficult to peel off, inconvenient, etc., and achieve the effects of sufficient stable protection, easy operation, and convenient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

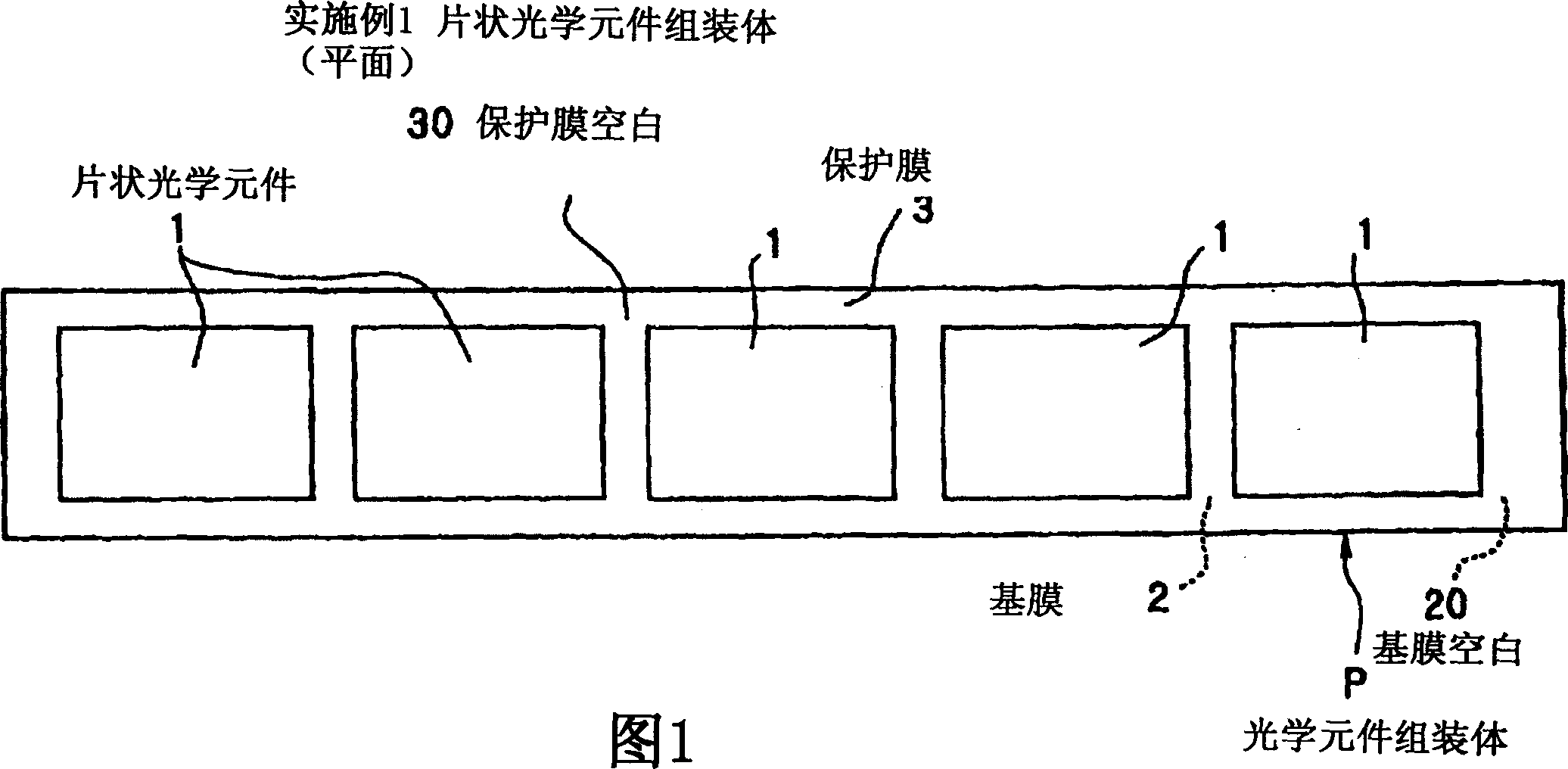

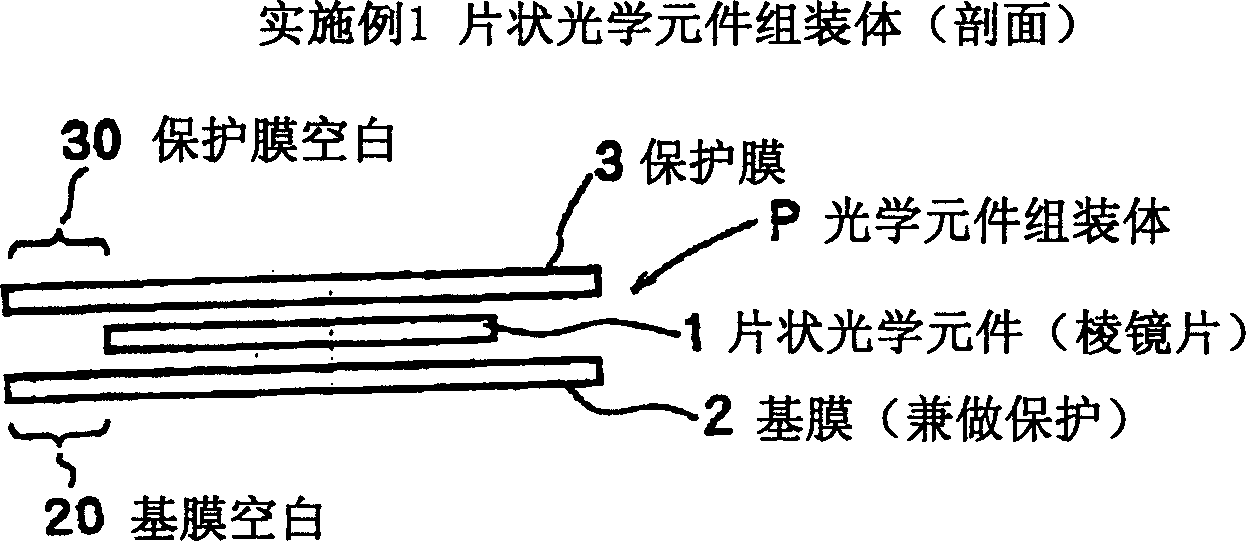

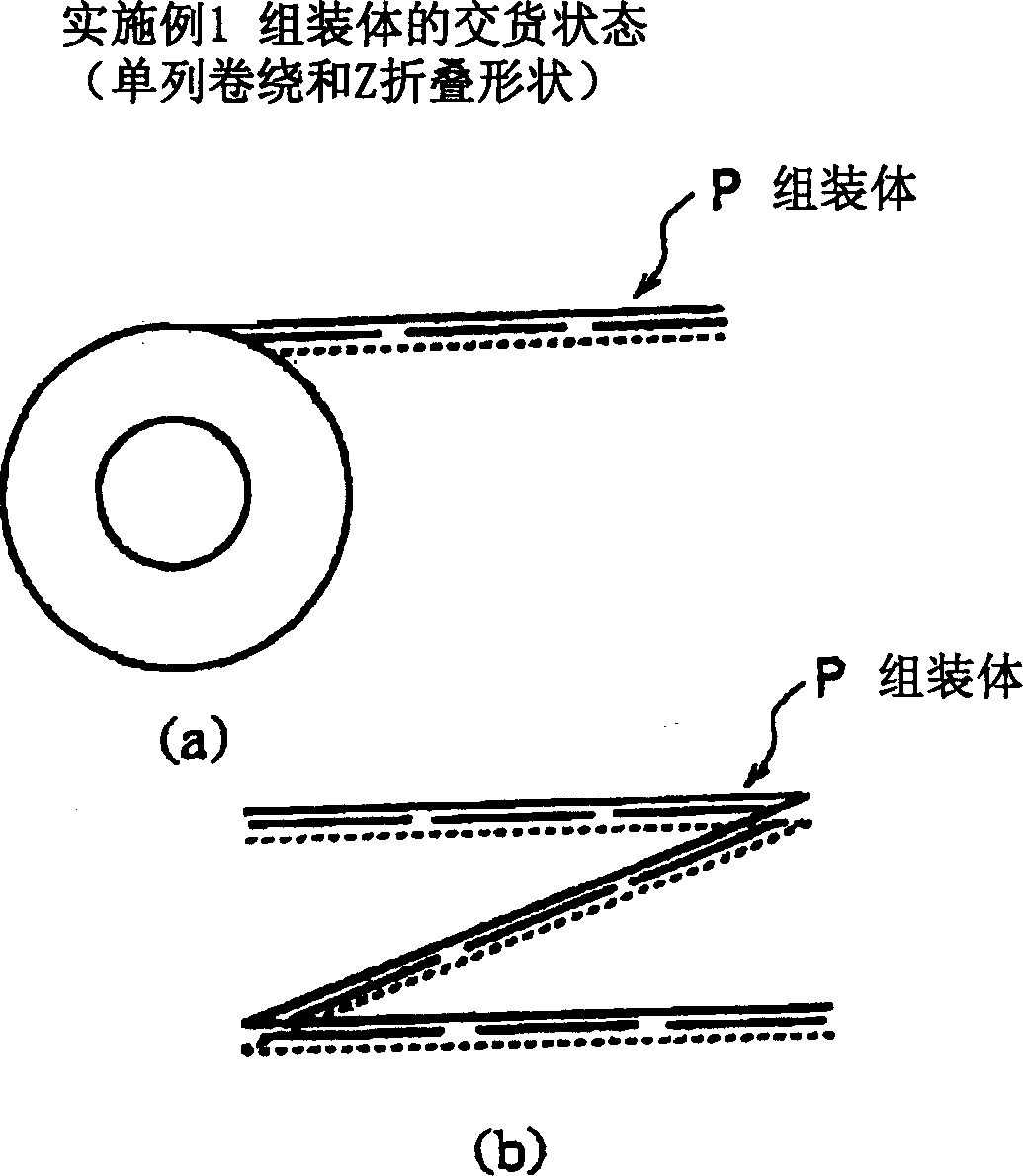

[0145] This embodiment is an example in which the present invention is specifically applied to an assembly of sheet-shaped optical elements in a backlight system of a liquid crystal screen of a handheld phone, a portable information terminal (device called a PDA, etc.), a digital camera, a portable game machine, and the like. Here, a prism sheet having light-collecting and refracting properties is used as the sheet-shaped optical element. The light collection and refraction of the prism sheet used as the sheet optical element used in this embodiment are designed to make the light of the light source evenly distributed on the liquid crystal screen, but it can also be designed to form various shapes on the screen according to other styles. light distribution. Refer to Figure 1 to Figure 4 .

[0146] In this embodiment, the assembled products are in a state of being sandwiched between protective sheets in a state of being neatly arranged in a certain direction. In particular,...

Embodiment 2

[0168] Refer below Figure 5 and Figure 6 Example 2 of the present invention will be described.

[0169] In this example, as using Figure 8 As described above, the first sheet-shaped optical element 1a and the second sheet-shaped optical element 1b perpendicular to the optical directionality of the first sheet-shaped optical element 1a are laminated in the above-mentioned order to obtain at least the above-mentioned laminated Structural part of the sheet optical element assembly.

[0170] refer to Figure 5 .

[0171] In this embodiment, the sheet optical element 1a, the second optical sheet element 1b perpendicular to the optical directionality thereof, and other diffuser sheets 7 required for constituting the sheet optical element assembly P should be placed relative to each other. The traveling direction D1 of their base film 2 is conveyed in the vertical direction D2, and on the base film 2, the sheet-shaped optical element 1a, the sheet-shaped optical element 1b, an...

Embodiment 3

[0208] Embodiment 3 of the present invention will be described below with reference to FIG. 7 .

[0209] In this example, as using Figure 8 As described above, the first sheet optical element 1a (front side) and the second sheet optical element 1b (back side) perpendicular to the optical directivity of the first sheet optical element 1a (back side) are laminated in this order. , to prepare an assembly for obtaining a sheet-shaped optical element assembly having at least the above-mentioned layered structure portion. In this embodiment, the diffusion sheet 7, the light guide plate 6, and the reflective sheet 5 are further stacked in this order to obtain the following Figure 8 The plate optic assembly of the illumination system shown.

[0210] Refer to Figure 7.

[0211] In this embodiment, a bracket 10 having sheet-shaped optical element assembly storage parts 10a to 10e composed of a plurality of recessed parts is used, and the sheet-like optical element assembly storage pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com