Planar display with touch panel

A flat-panel display, touch panel technology, applied in the direction of instruments, chemical instruments and methods, data processing input/output processes, etc., can solve the problems of increasing the weight of the display module, the depth of field, and increasing the thickness and weight of the display module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Some embodiments of the invention are described in detail below. However, the invention may also be practiced broadly in other embodiments than those described in detail, and the scope of the invention is not limited only by the appended claims.

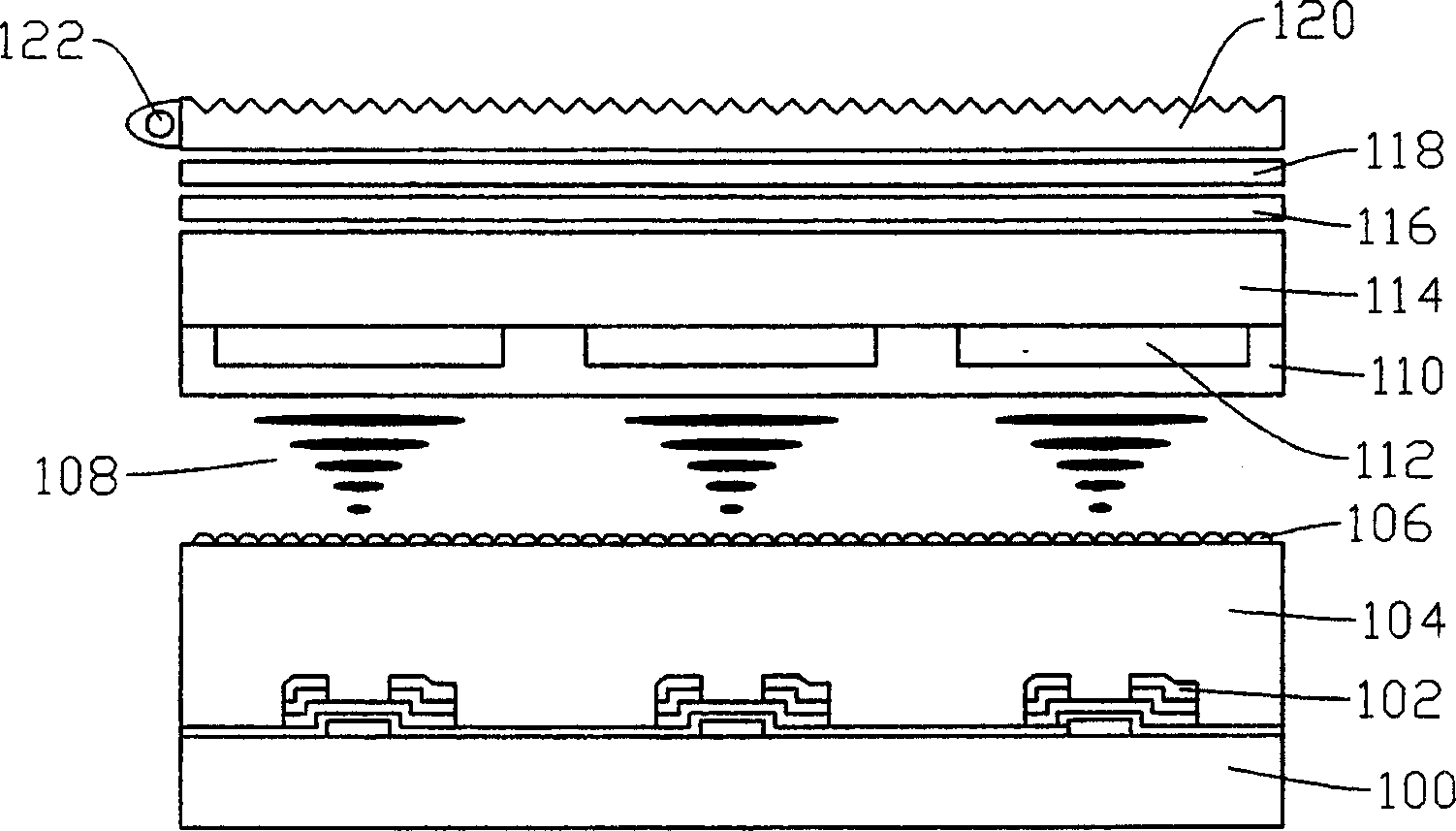

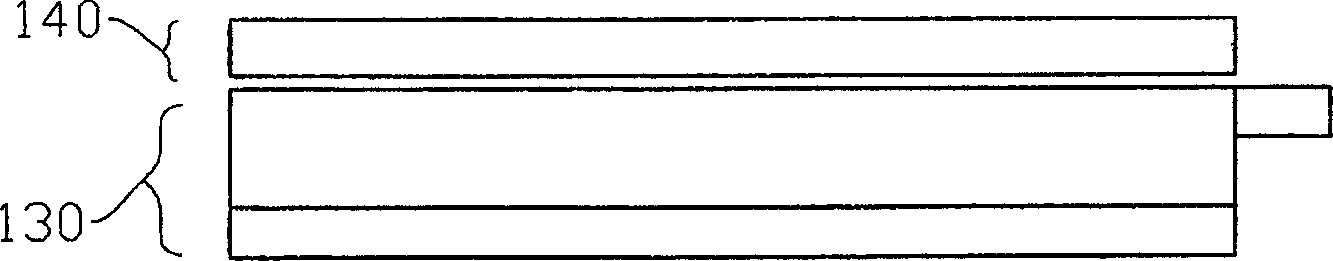

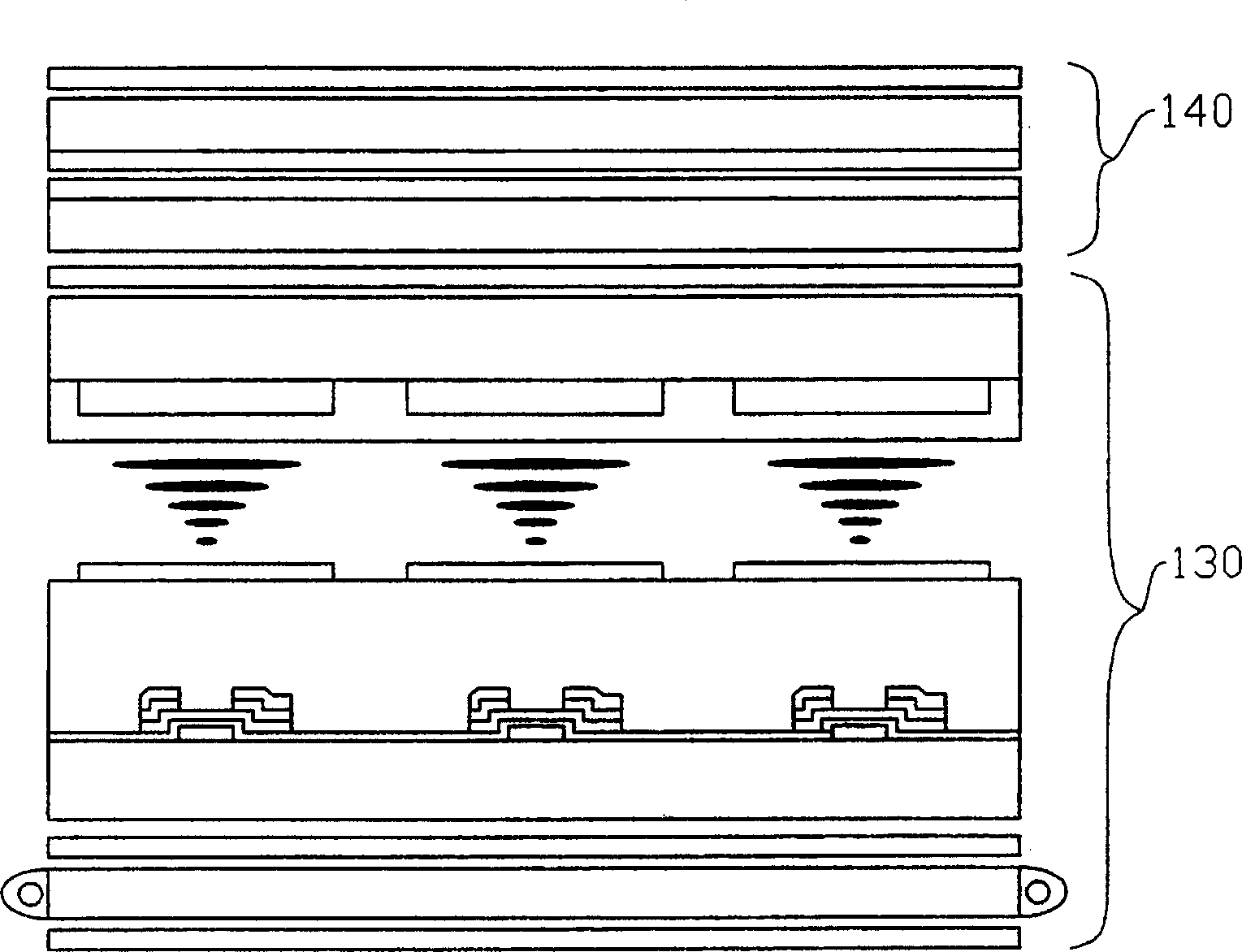

[0044] The present invention mainly provides a flat panel display with a touch panel, including a reflective liquid crystal display and a touch panel. The above-mentioned reflective liquid crystal display at least includes a transparent substrate and a light source located on one end surface of the above-mentioned transparent substrate, wherein the above-mentioned transparent substrate is a light guide plate, and its material can be a plastic substrate. The above-mentioned touch panel is located on the aforementioned reflective liquid crystal display, and at least includes a first transparent conductive layer on the aforementioned transparent substrate, an adhesive layer located on the aforementioned first transparent conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com