Calandria air-gap discharge ozone generator

An ozone generator and air gap technology, applied in the field of ozone generators, can solve problems such as short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

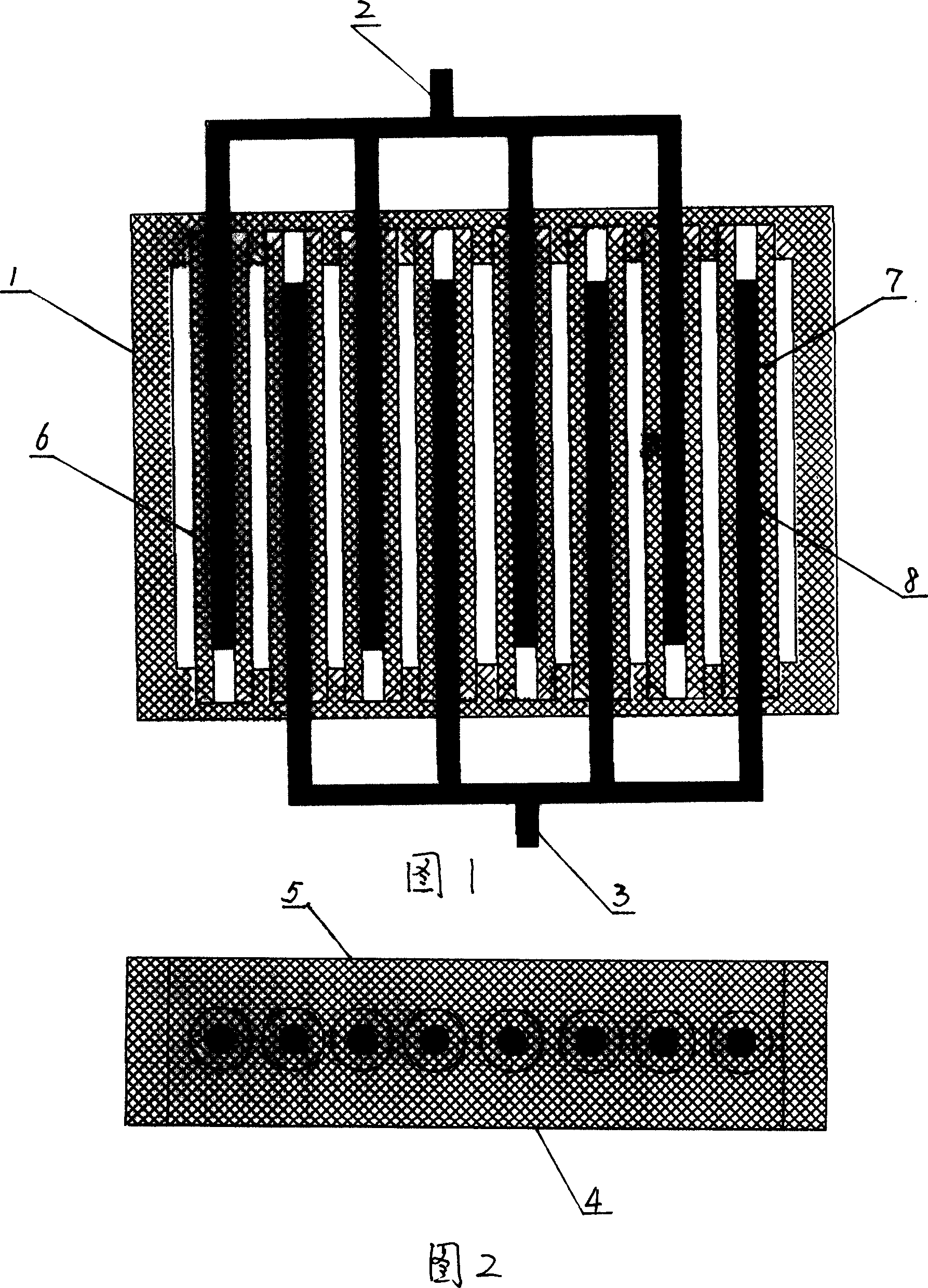

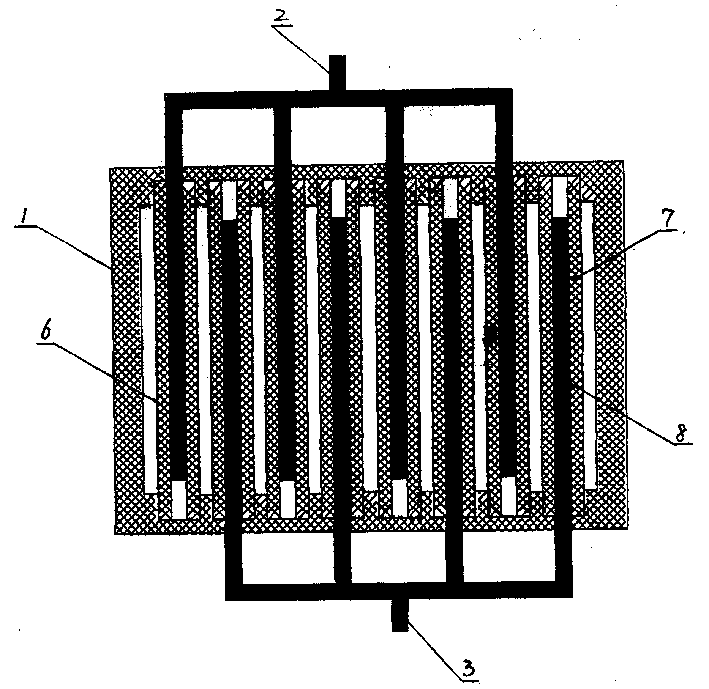

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0014] Please refer to Fig. 1 and Fig. 2. In the figure, the discharge chamber 1 is composed of a side porcelain fixed plate and a side porcelain fixed plate. The high-voltage and high-frequency input 2 and 3 are fixed on the end porcelain fixed plate of the discharge chamber 1. The air inlet 4 and the air outlet 5 are opened on the side porcelain fixing plate, and the discharge pipe electrode 6 is fixed on the end porcelain fixing plate of the discharge chamber 1, and the discharge chamber 1 is divided into several equal-volume spaces, and the discharge pipe electrode is divided into 6 points. There are at least two negative and positive poles, which are arranged in parallel and spaced apart. The tube electrodes 6 are composed of alumina ceramic tubes 7 that evenly wrap conductors 8. They are connected in parallel with high-voltage and high-frequency inputs 2 and 3 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com