Needle set

A needle group and needle butt technology, which is applied in the field of needle group of knitting machines, can solve problems such as the collision of needle butts and cam parts, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

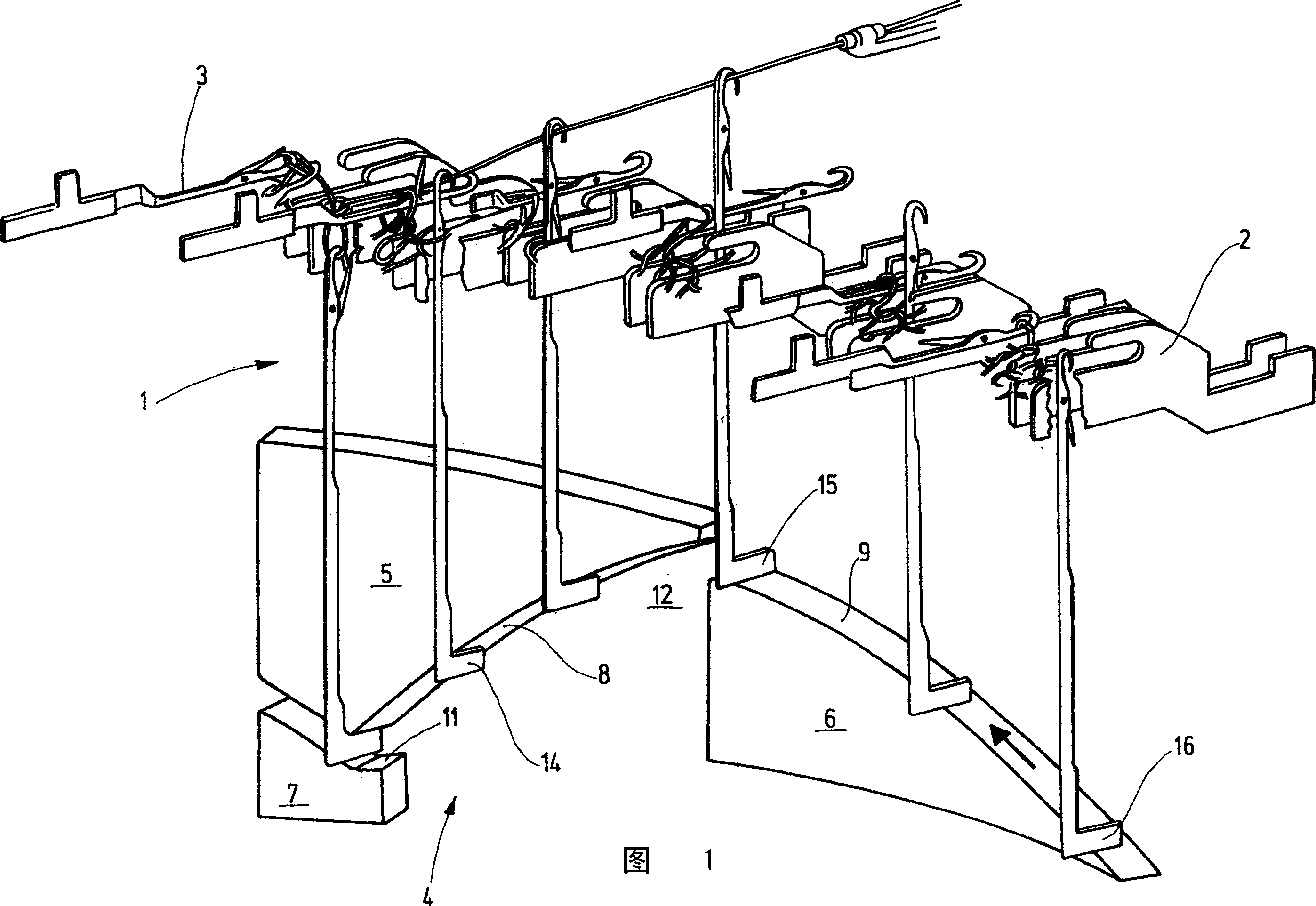

[0023] FIG. 1 shows a needle group 1 which, together with sinkers 2 and further needles 3 arranged transversely to said first needle 1, forms a knitting system of a knitting machine. Needle 1 is driven by a cam 4 formed by cam segments 5,6,7. These triangular parts define a triangular groove 12 with guide surfaces 8 , 9 , 11 . This slot is used to drive the butts 14 , 15 , 16 of the needle 1 into the triangular slot 12 .

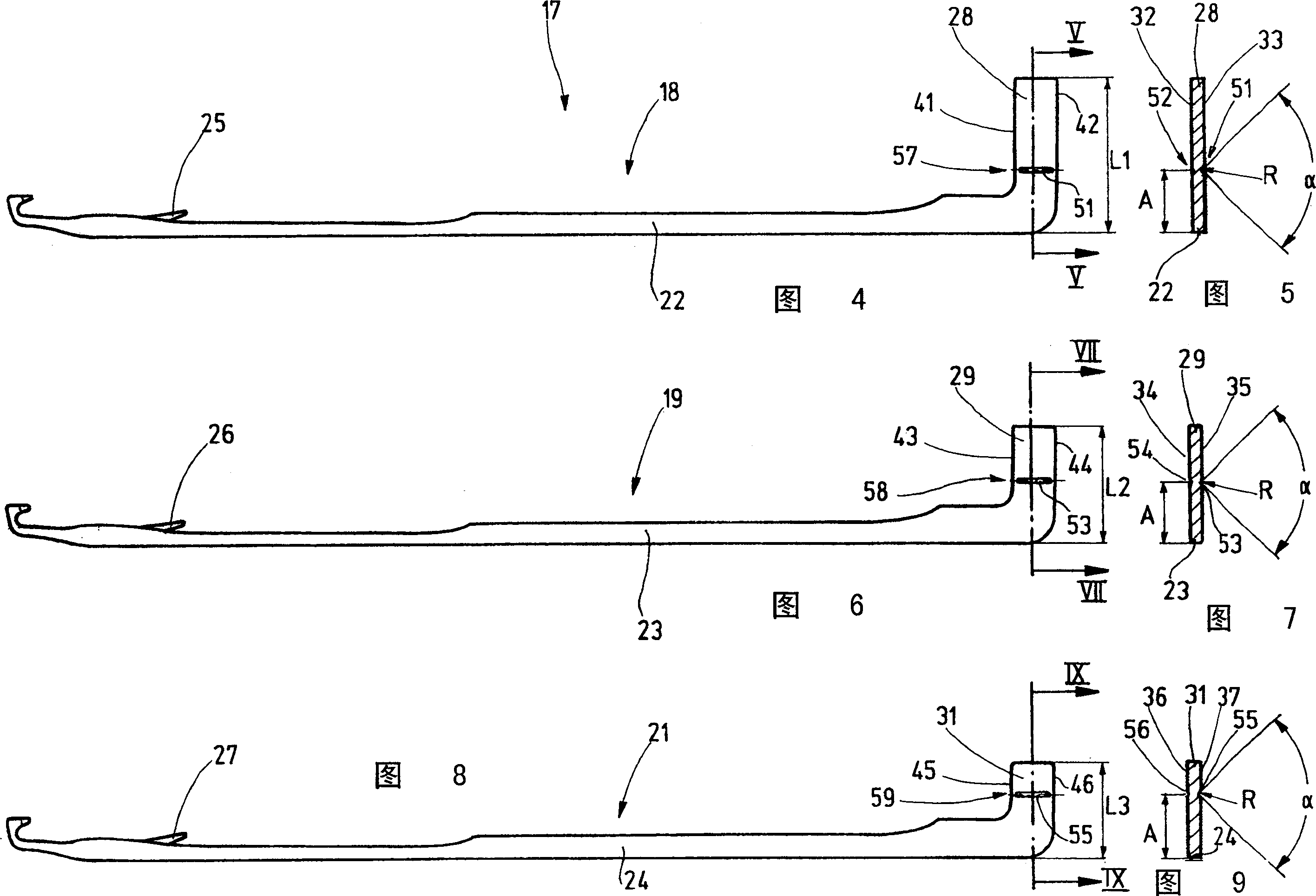

[0024] These needles 1 form a needle set 17 of three needles, indicated by needles 18 , 19 , 21 shown in FIGS. 4 , 6 and 8 . These needles 1 in FIG. 1 comprise needles 18 , 19 , 21 of needle set 7 , for example. These needles 18, 19, 21 have a needle bar 22, 23, 24 respectively, the end of which has a hook. The needles 18 , 19 , 21 are designed, for example, as latch needles, so that a pivotable latch next to each hook opens and closes in a controlled manner.

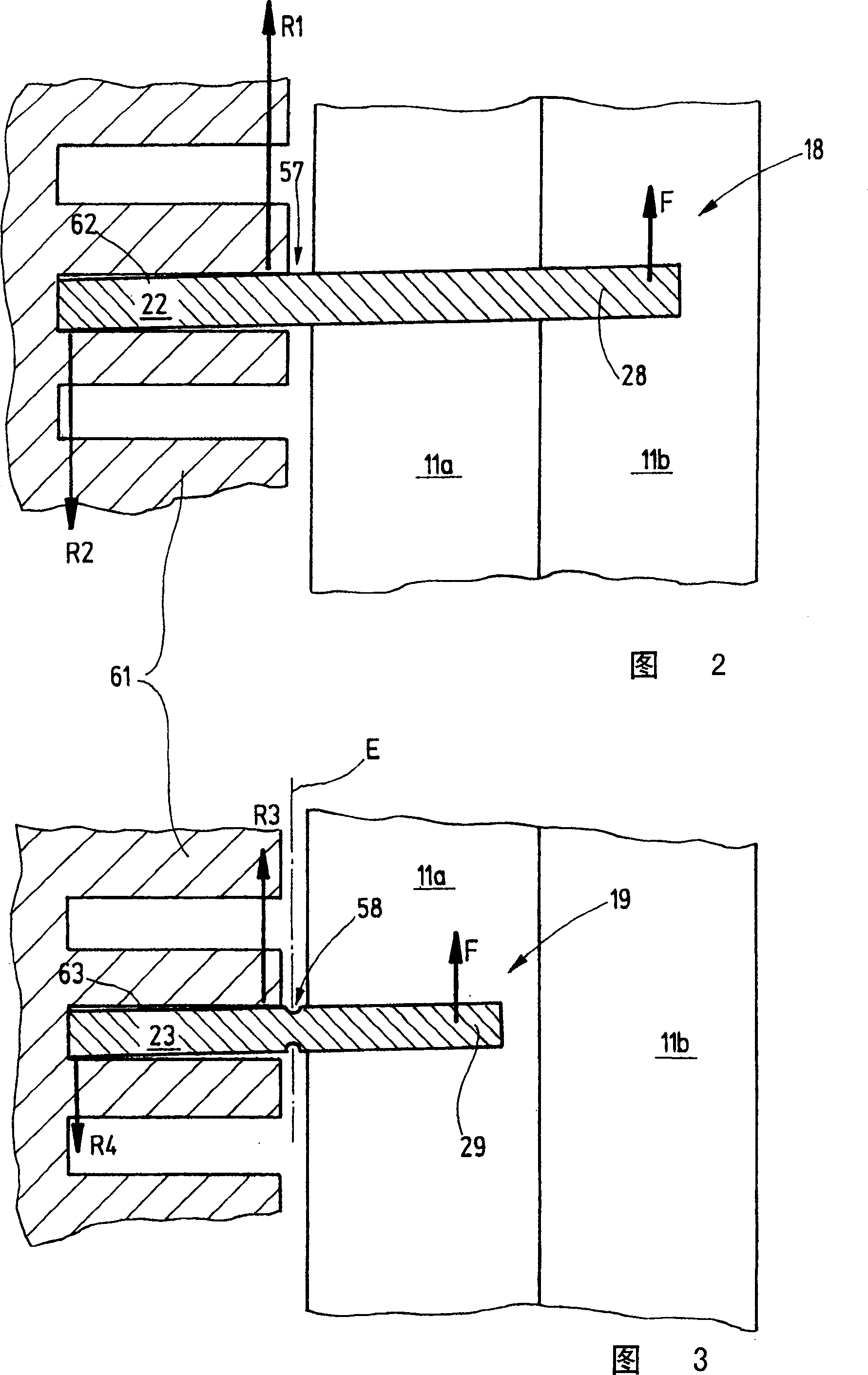

[0025] Needle shanks 22, 23, 24 of needles 18, 19, 21 have a needle butt 28, 29, 31 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com