Device for sterilizing containers to be filled

A disinfection device and container filling technology, which is applied in disinfection, packaging sterilization, chemistry, etc., can solve problems such as unfavorable work efficiency and expensive technical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

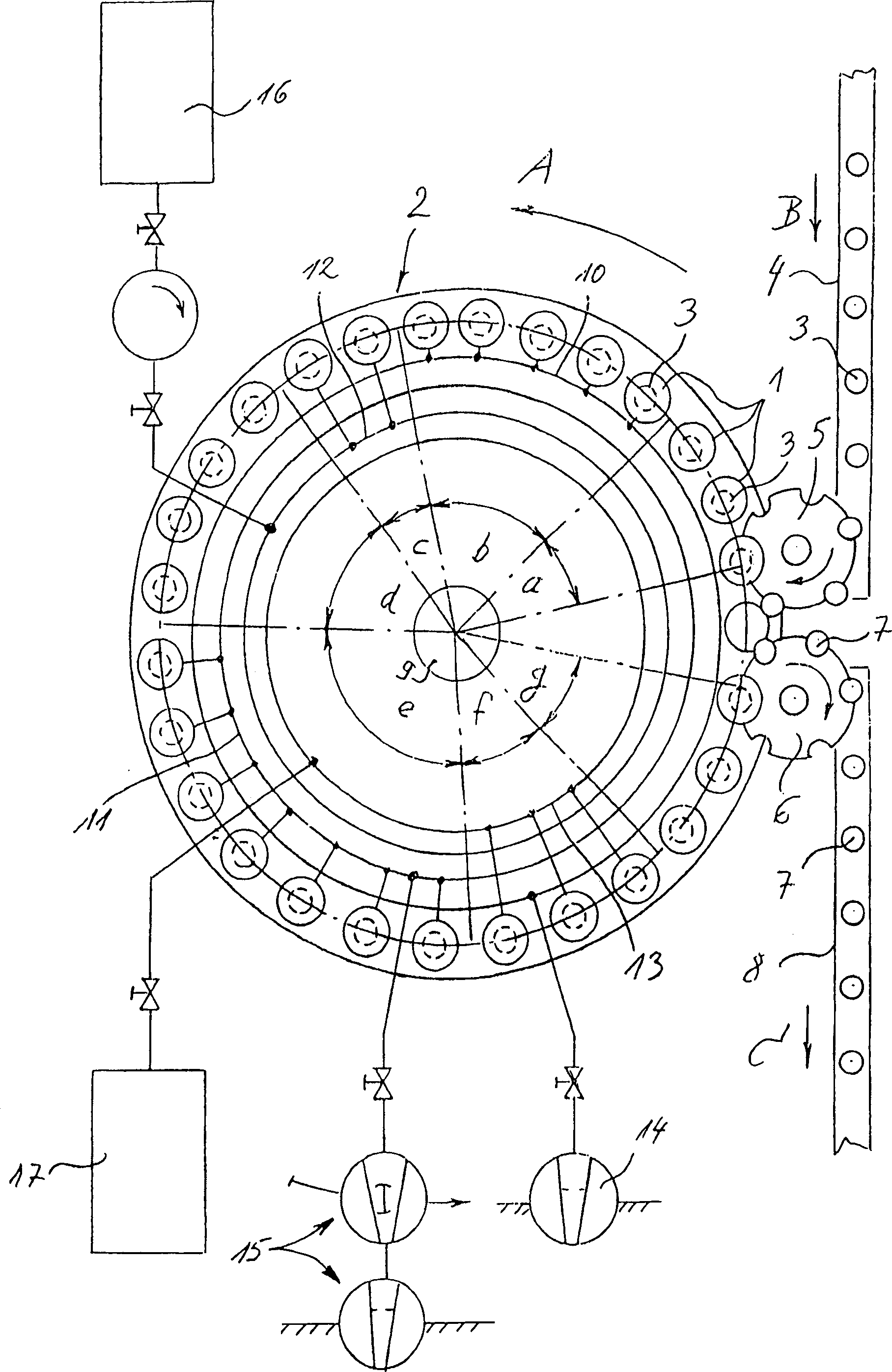

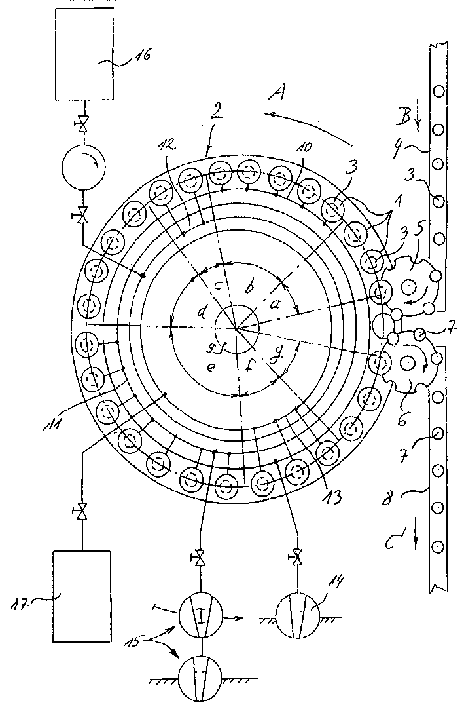

[0015] According to this figure, a plurality of sterilization chambers 1 can be arranged on the periphery of a revolving gantry 2 whose conveying movement direction is indicated by A. In FIG. For example, there may be 100 such sterilization chambers 1 . Each sterilization chamber 1 accommodates a container 3 to be sterilized. The containers 3 are supplied to the revolving crane 2 in the conveying direction B, for example by means of a conveying device 4 which is only schematically indicated. Via a star feed 5 that rotates in the direction of the arrow, the containers 3 continuously reach the area below the sterilization chamber 1 and enter the sterilization chamber. Accordingly, there is a star-shaped delivery mechanism 6 rotating in the direction of the arrow, by means of which the sterilized and possibly filled closed containers 7 are sent out again in the delivery direction C by a delivery device 8 .

[0016] If, for example, the revolving gantry 2 is equipped with fifty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com