Method for producing light guide plate and mold

A manufacturing method and technology for manufacturing molds, which are applied in the field of light guide plate manufacture and molds, can solve the problems of poor uniformity of wedge-shaped or dish-shaped light guide plates, and achieve the effects of uniform shape, good uniformity, and good optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

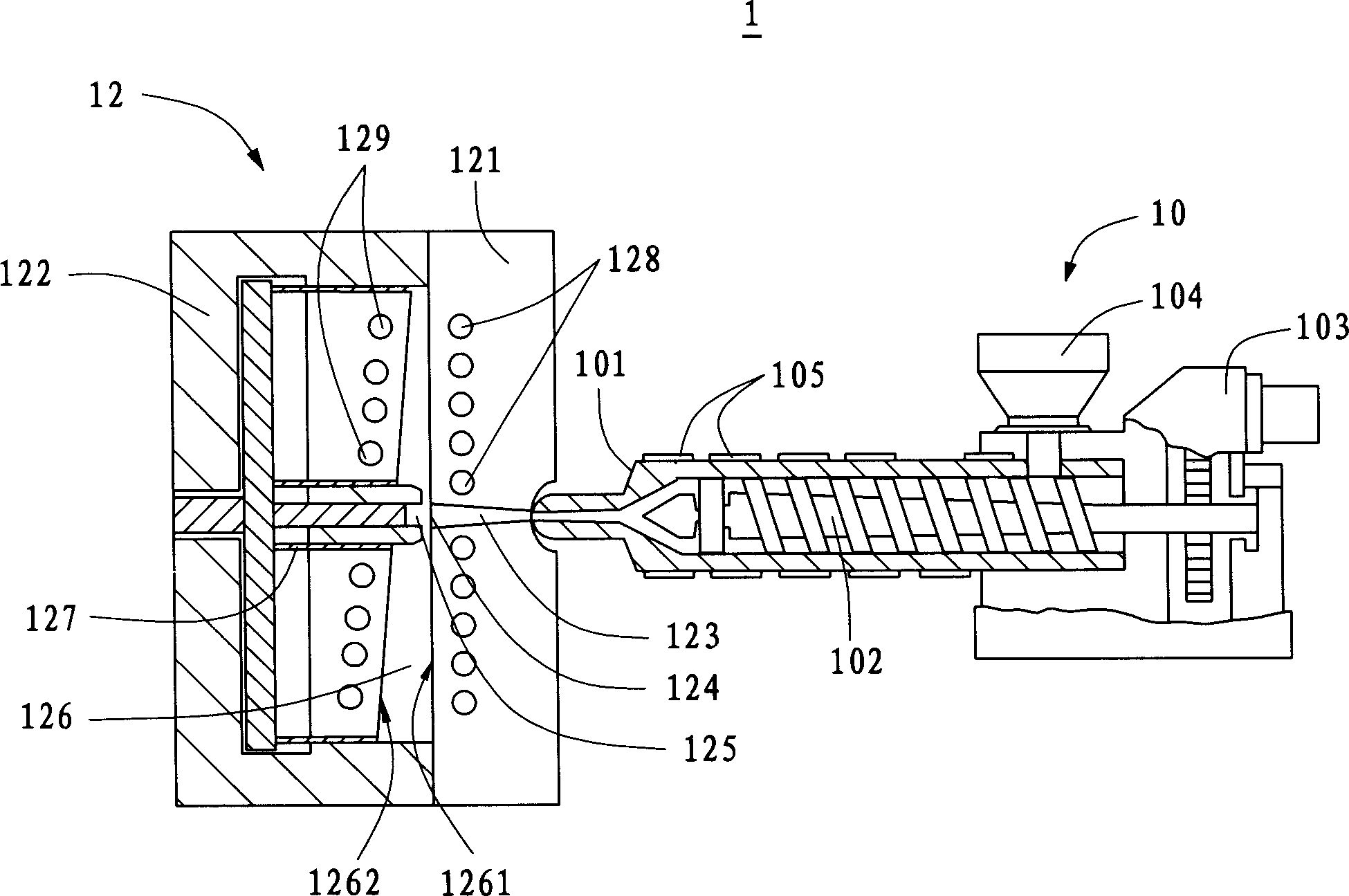

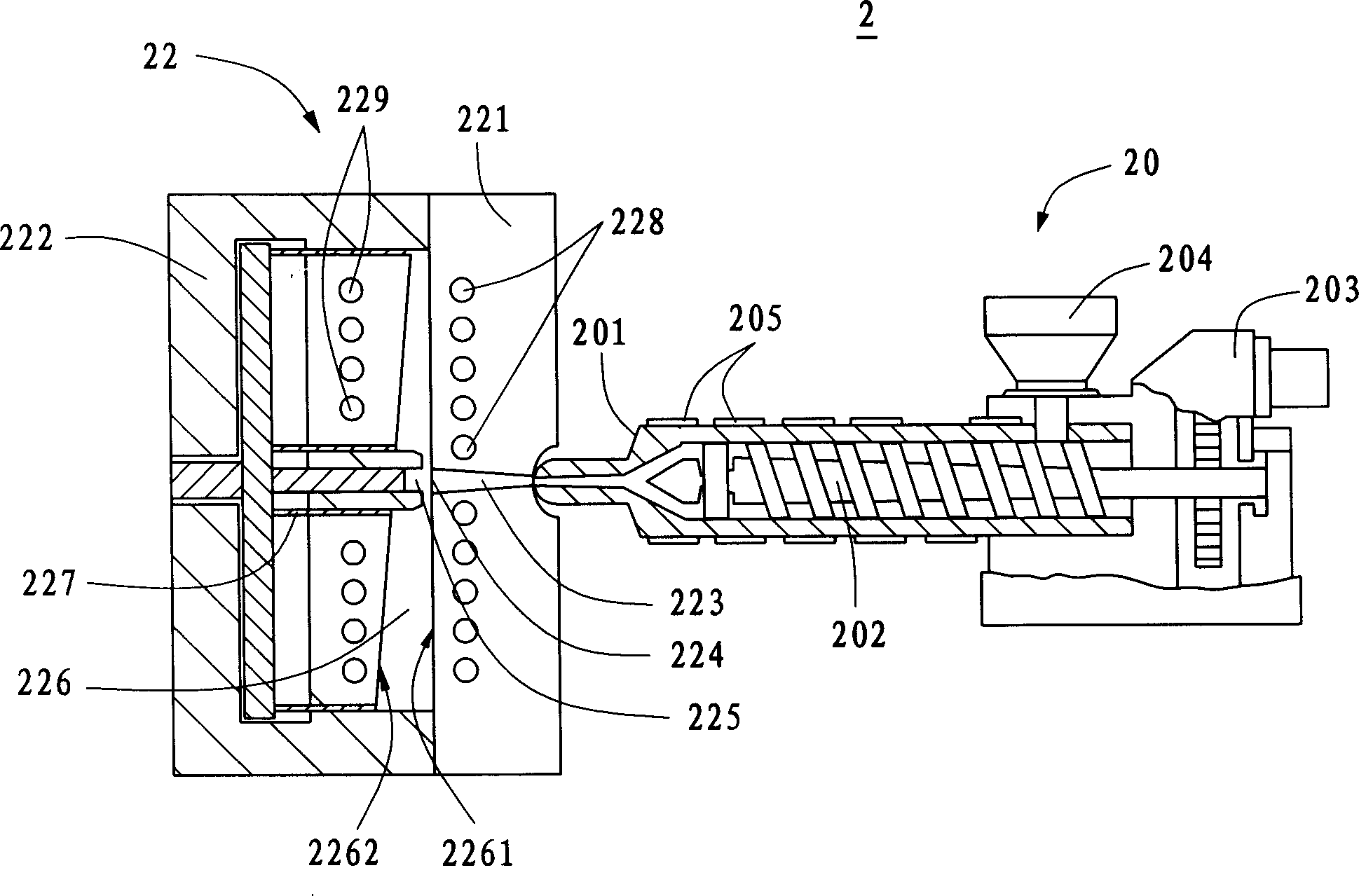

[0018] See figure 2 , Is the first embodiment of the molding device used in the manufacturing method of the light guide plate of the present invention. The molding device 2 includes an injection device 20 and a mold 22. The injection device 20 includes an injection barrel 201, a screw 202 rotatably driven in the barrel 201, a motor 203 that drives the screw 202, a hopper 204 that supplies resin material into the barrel 201, and a hopper 204 provided on the outer surface of the barrel 201 Heater 205. The mold 22 includes a fixed mold 221, a movable mold 222, a channel 225 connecting the two front ends of the fixed mold 221 and the movable mold 222, a flow channel 223 through which molten resin passes and a gate communicating with the flow channel 223 are formed in the fixed mold 221 224. The refrigerant passage 228 of the fixed mold 221 and the refrigerant passage 229 of the movable mold 222. Wherein, the fixed mold 221 and the movable mold 222 form a wedge-shaped mold cavity 226 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com