Heat pipe vacuum tube solar energy heat collector

A technology of vacuum tube collectors and glass vacuum tubes, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., and can solve problems such as performance degradation and thermal performance degradation in summer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

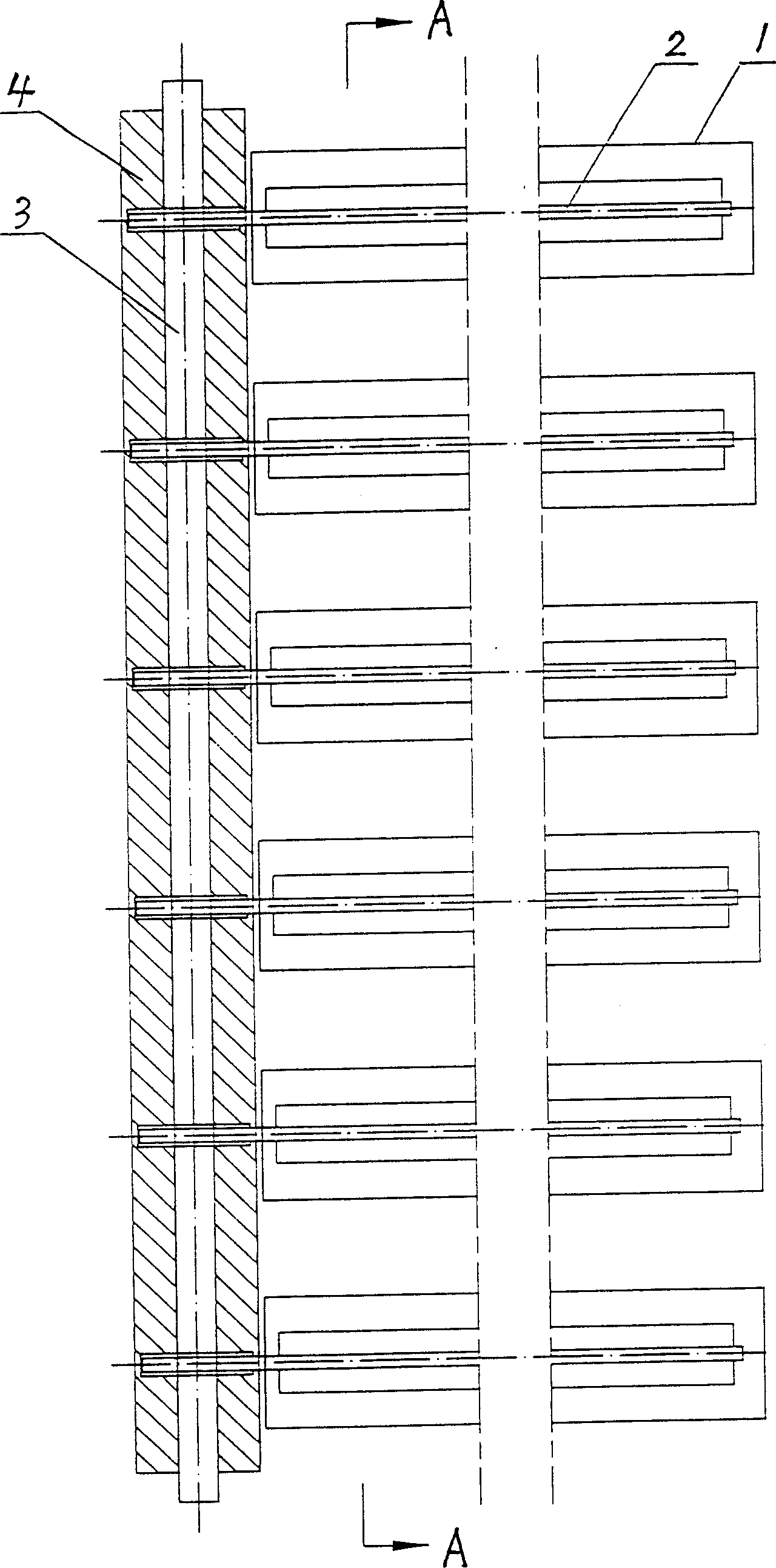

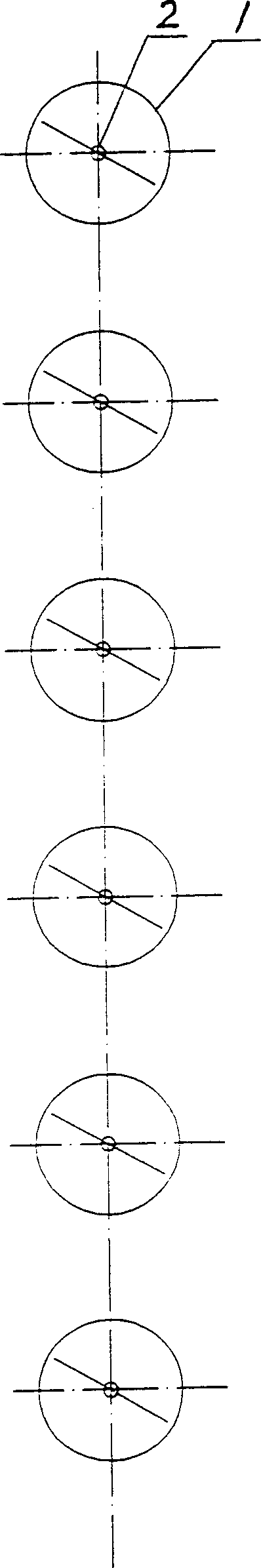

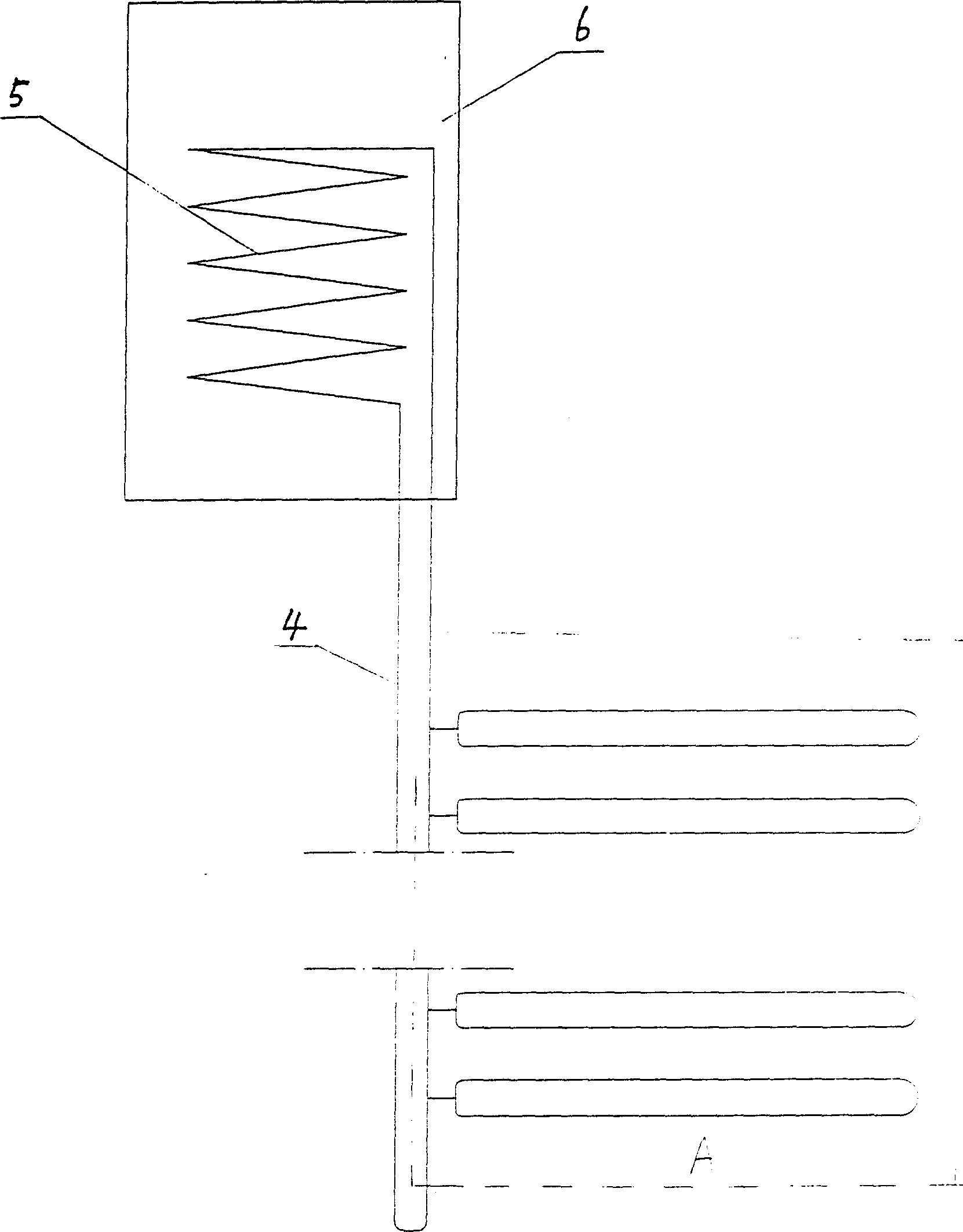

[0016] see first figure 1 and 2 , this figure is a solar heat collector with heat pipe vacuum tubes placed horizontally according to the first embodiment of the present invention.

[0017] This embodiment is composed of a glass tube 1 , a gravity heat pipe 2 with ribs, a header 3 and an insulating material 4 .

[0018] The glass tube 1 and the gravity heat pipe 2 inside are placed horizontally, and the fins of the gravity heat pipe 2 can be selected to form an optimal angle with the ground according to the local latitude. The inner diameter of the evaporation section of the gravity heat pipe 2 is greater than 9mm, but considering the linearity of the heat pipe in actual production, the instability of installation and the cost of consumables, the inner diameter is preferably between 12mm and 15mm. The working mass to be filled is greater than 10% of the volume of the evaporating section, but the liquid filling volume should not be too high, otherwise there will be too much li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com