Dryness measurement device

A technology for measuring device and dryness, which is applied in washing devices, household clothes dryers, textiles and papermaking, etc., and can solve problems such as inaccurate measurement of dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will now be described in detail with reference to the embodiments shown in the accompanying drawings.

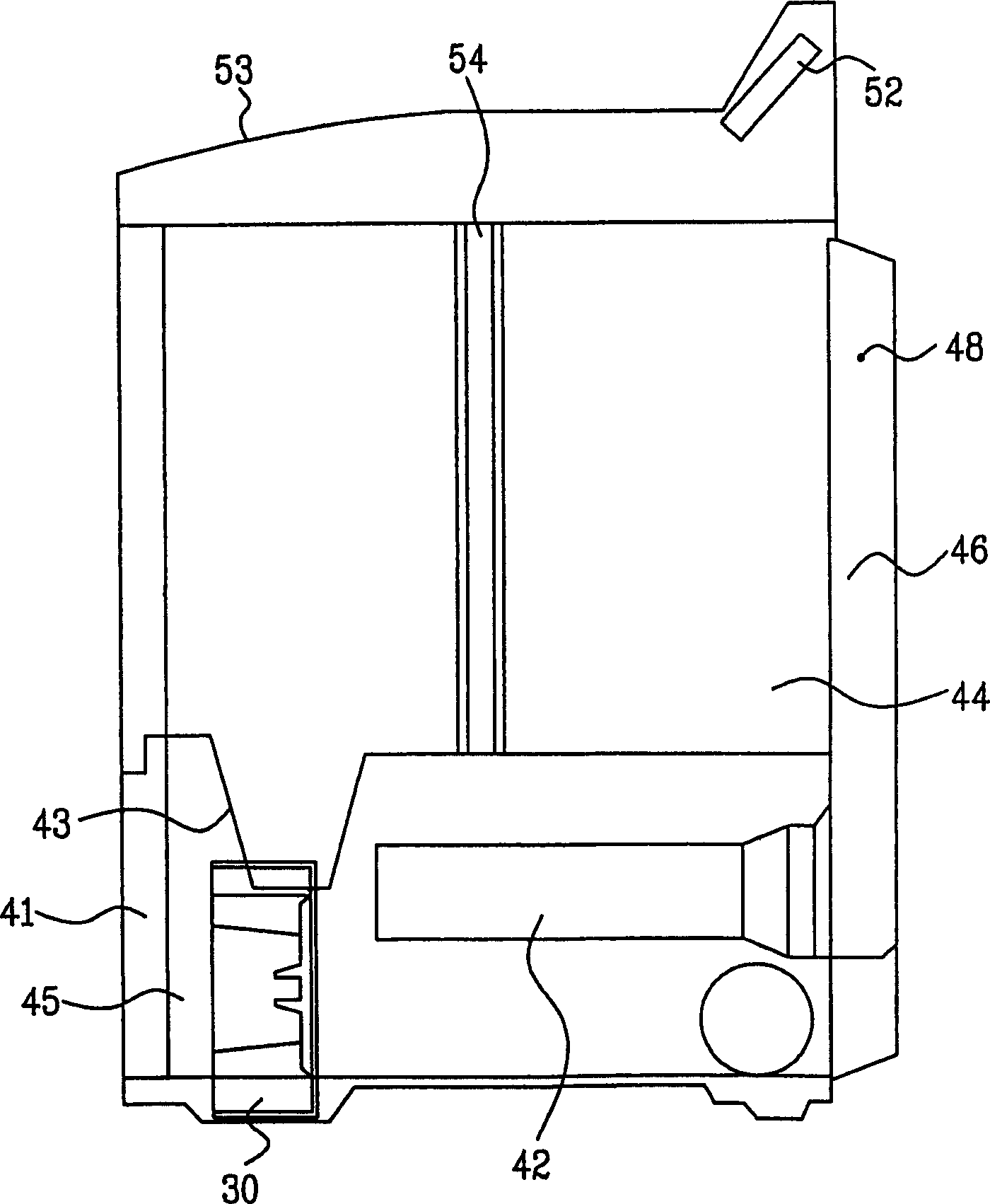

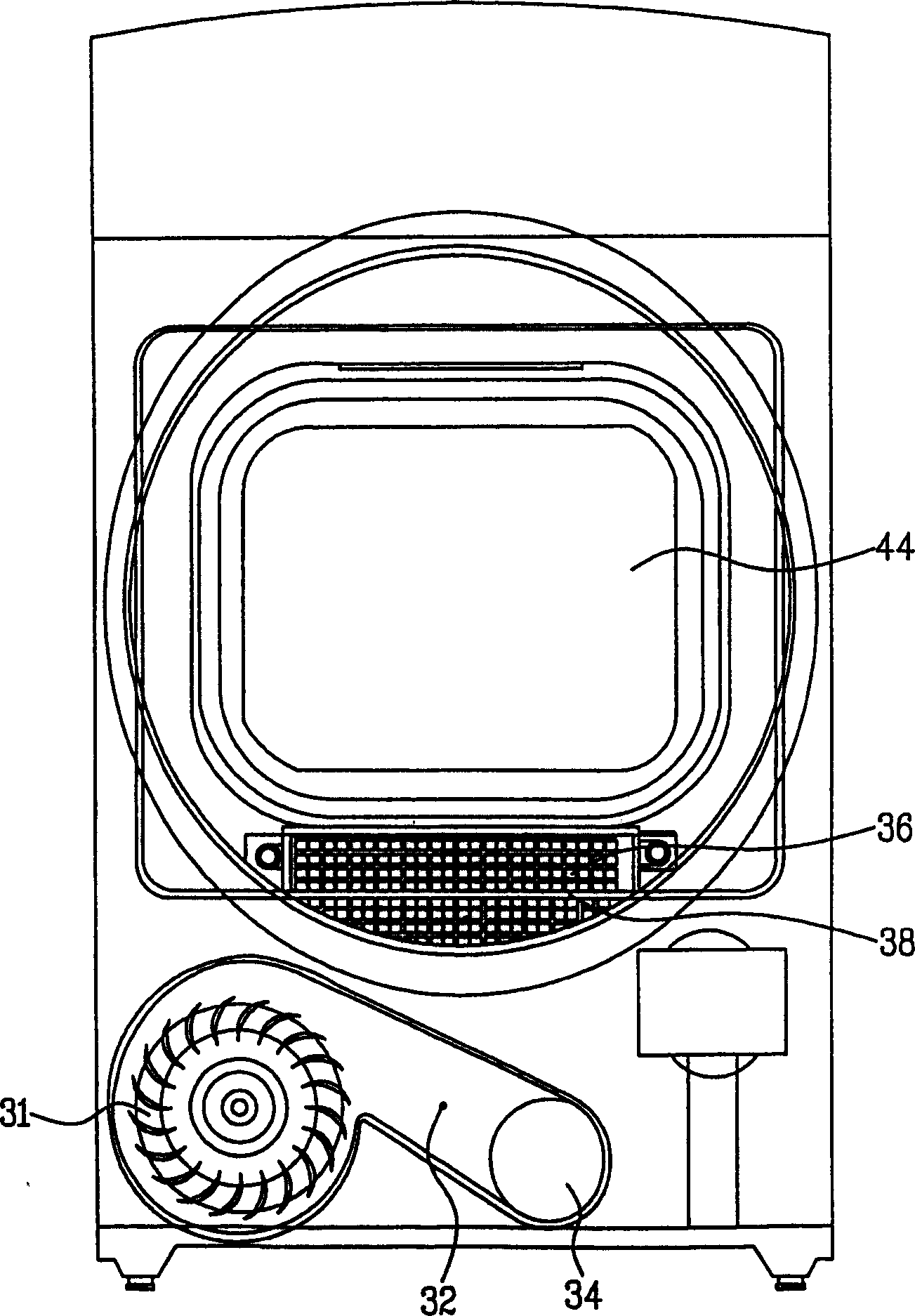

[0029] Figure 5 Shown is the structure of the dryness measuring device in the dryer according to the present invention, wherein the required explanation of the structure of the dryer will refer to FIGS. 1 to 3 .

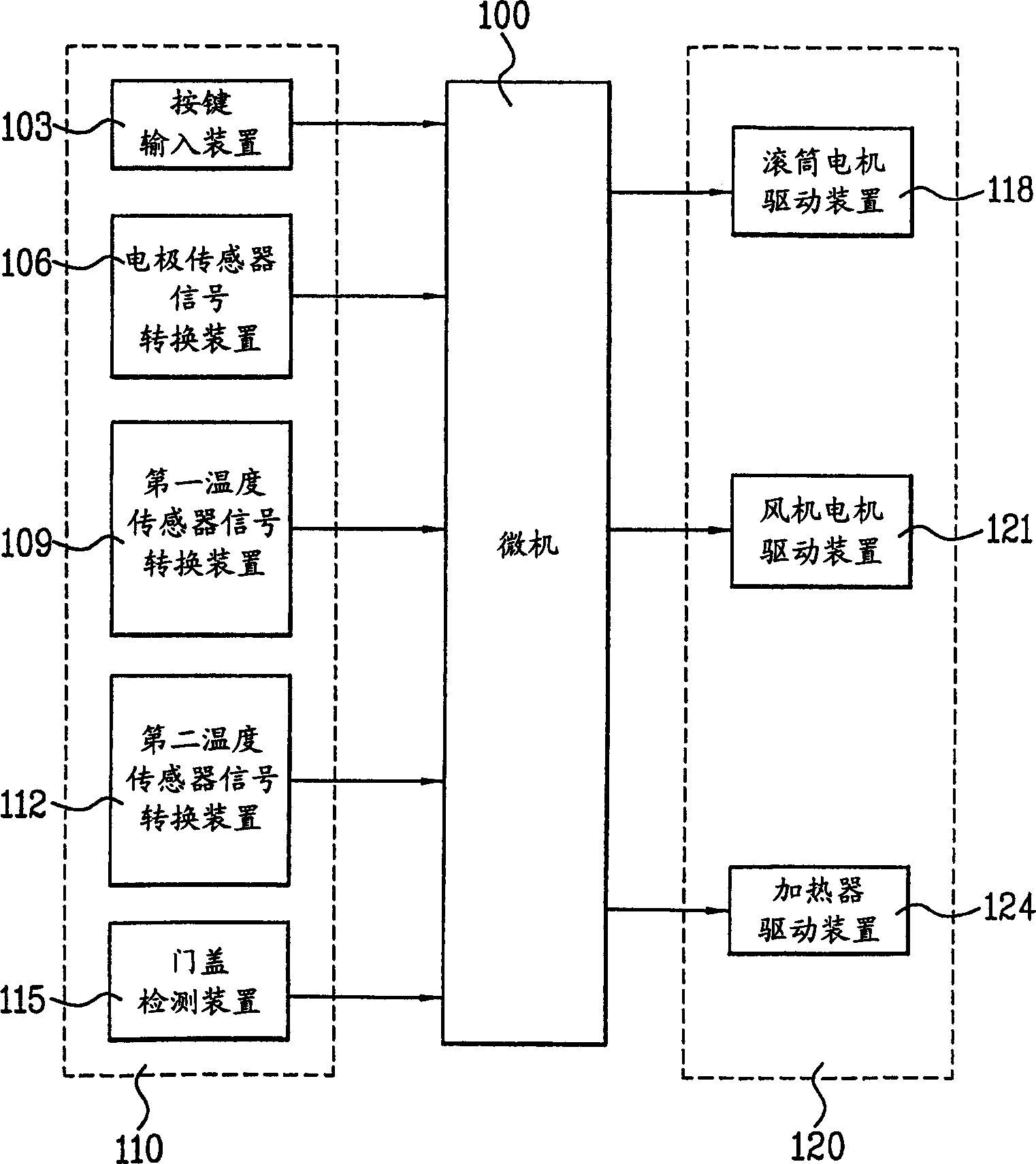

[0030] refer to Figure 5 , in the dryness measuring device of the present invention, the electrode sensor 38 and the capacitor C1 are respectively connected in series with the resistor R1, so that the charging voltage on the capacitor C1 varies with the impedance value of the electrode sensor 38.

[0031] The discharge circuit is provided between the electrode sensor 38 and the capacitor C1.

[0032] The discharge circuit includes a resistor R2 and a transistor Q1 as switching means. When the transistor Q1 is turned on under the control of the microcomputer 100, the charged voltage of the capacitor C1 is rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com