Tooth hydraulic chain tensioner with rotary reset and locking means

A technology with tensioner and ratchet, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., and can solve problems such as chain tension fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

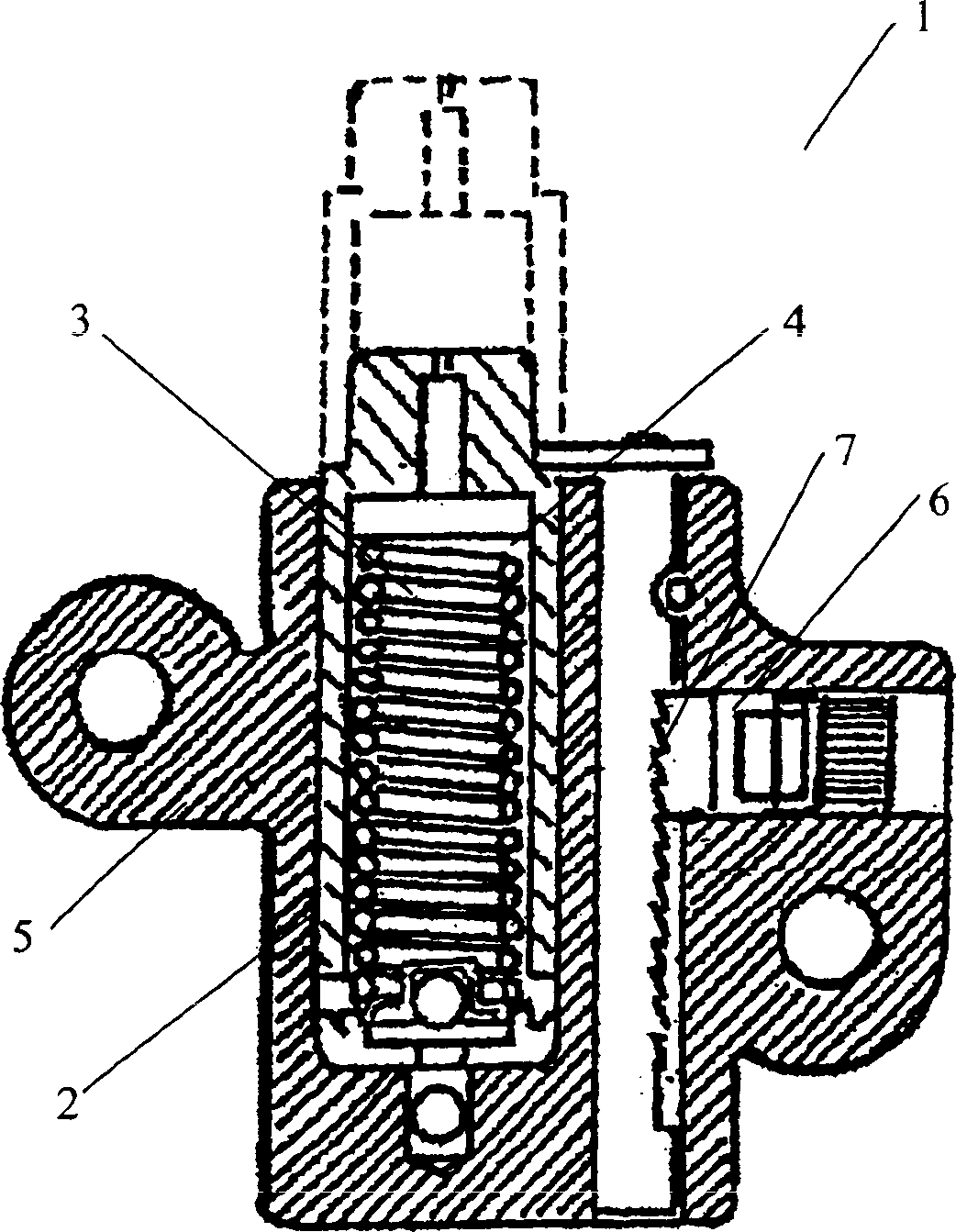

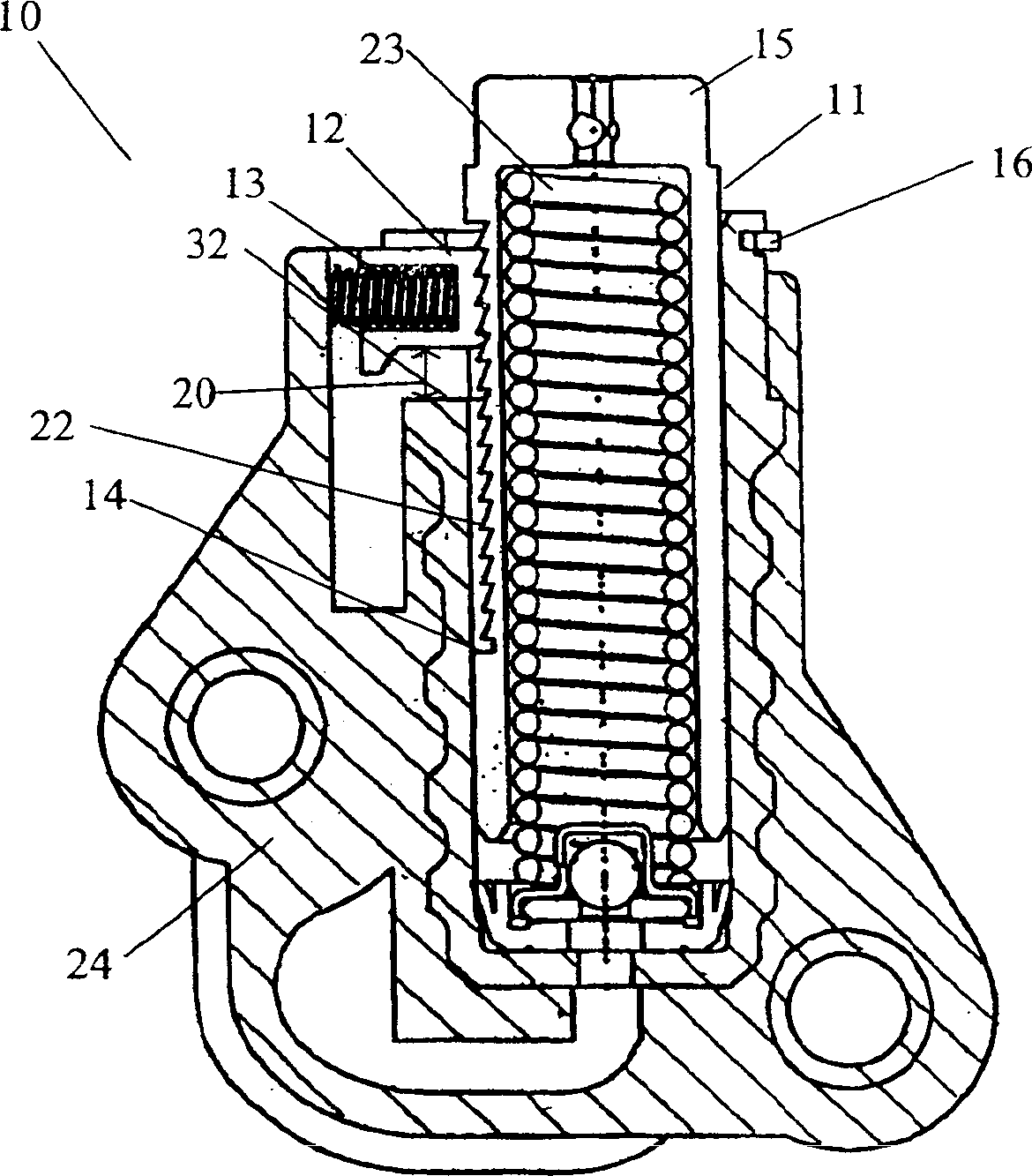

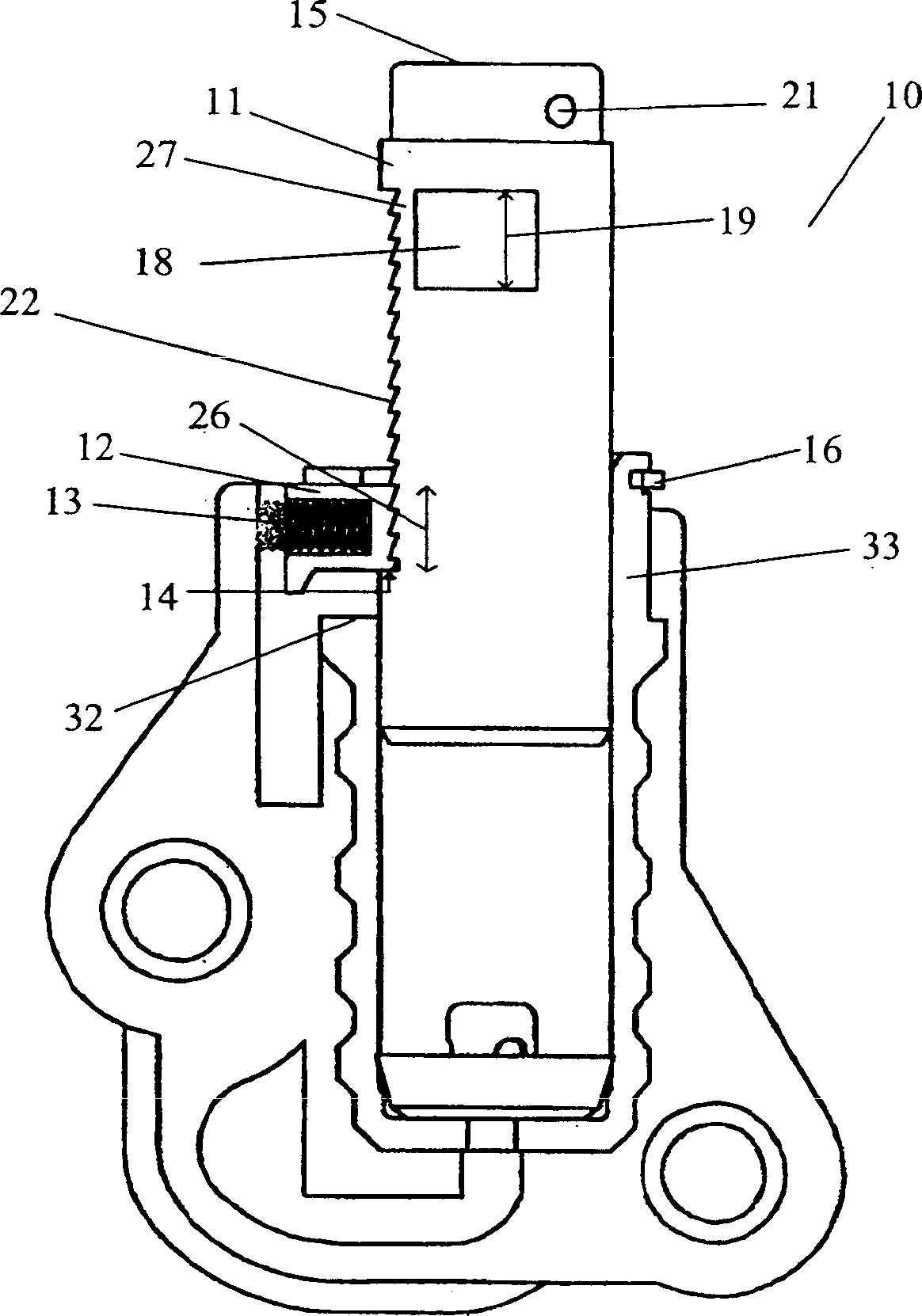

[0017] refer to Figures 2 to 9 , the hydraulic piston tensioner 10 of the present invention has a toothing interface between the piston skirt 11 and the pawl 12 . A tensioner spring 23 biases the piston 15 in the direction of the chain (not shown). The piston is located within the housing 24 .

[0018] The meshing interface between the piston skirt 11 and the pawl 12 includes teeth 22 shaped to allow the piston 15 to extend when the slope of the tooth forces the pawl 12 away from the piston 15 and against the action of its spring 13 . The opposing faces of the teeth 22 prevent piston compression. The teeth 22 are sufficiently recessed into the skirt 11 to provide a shoulder 14 against which the pawl 12 compresses at the predetermined piston position. Even if the teeth are not engaged, the pawl 12 prevents further extension of the piston 15 .

[0019] The pawl 12 is positioned and constrained by the pawl spring 13 , the retaining ring 16 and a series of surfaces formed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com