Super high pressure air-actuated proportional pressure-reducing valve

A proportional pressure reducing valve, ultra-high technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of long adjustment time, to avoid pressure errors, improve response speed, and improve pressure control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

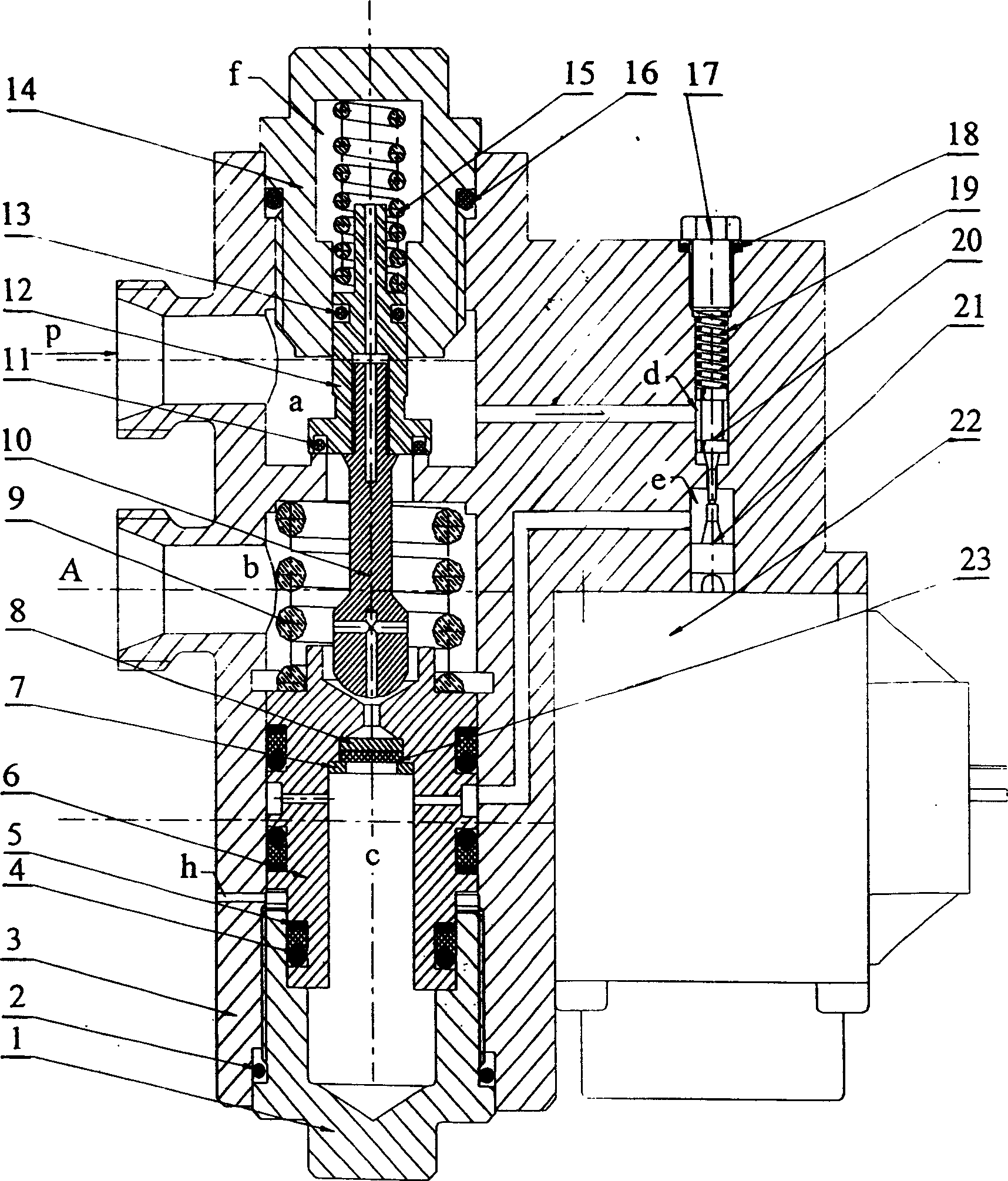

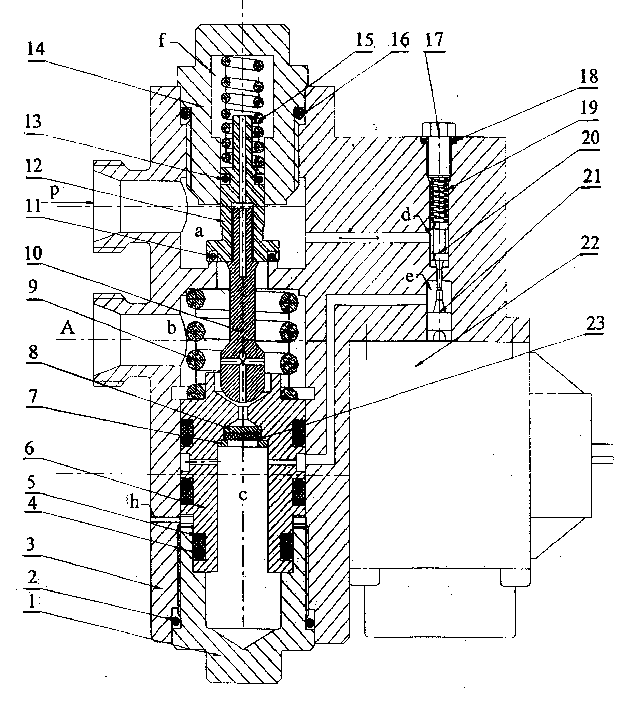

[0018] As shown in the accompanying drawings, the structure of the present invention can be functionally divided into two parts, the pilot valve stage and the main valve stage.

[0019] 1) Pilot stage: the pilot stage gas circuit is a C-type half bridge structure, the input end of the half bridge is led from the input end P of the high-pressure gas of the pressure reducing valve, and the pilot valve controlled by the proportional electromagnet 22 constitutes the dynamic gas damping of the input end, The output end of the half bridge is connected to the output end A of the pressure reducing valve, and the damping plate 23 constitutes the fixed damping of the C-type half bridge; the air inlet chamber d of the pilot stage has a first screw plug 17 and an O-shaped rubber seal from top to bottom. Ring 18, return spring 19, pilot valve spool 20, wherein the O-shaped rubber sealing ring 18 is used for sealing the upper end of the air intake chamber d of the pilot stage. A guide platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com