Method for manufacturing loess cinerary urn and loess cinerary urn manufactured by the method

An urn, loess technology, applied in the following fields, can solve the problems of surface damage, weak surface hardness, poor ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention is described with reference to the accompanying drawings.

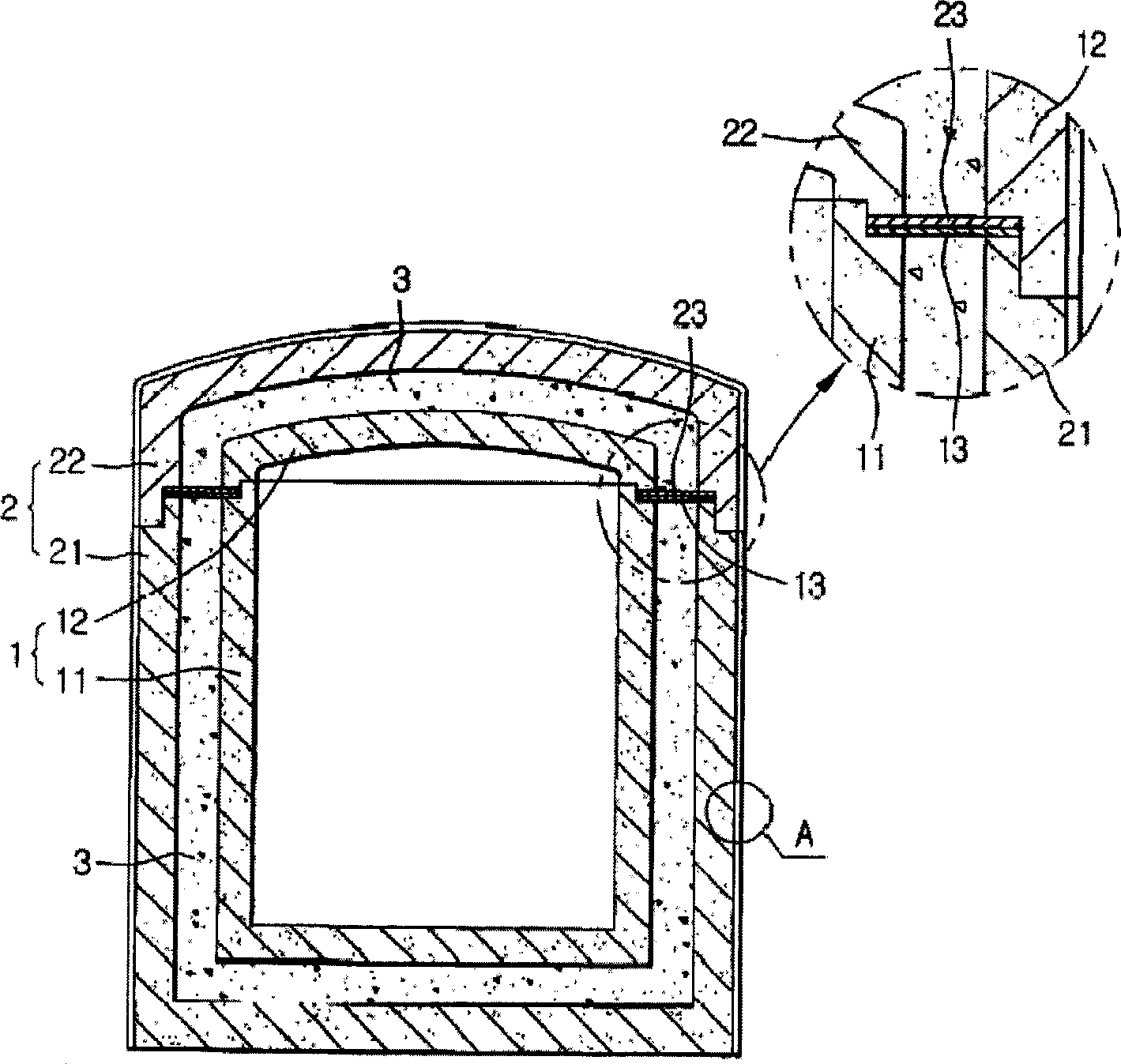

[0034] figure 1 is a cross-sectional view of the loess urn of the present invention, and figure 2 Yes figure 1 A magnified view of part A. First, the structure of the loess urn of the present invention is as follows.

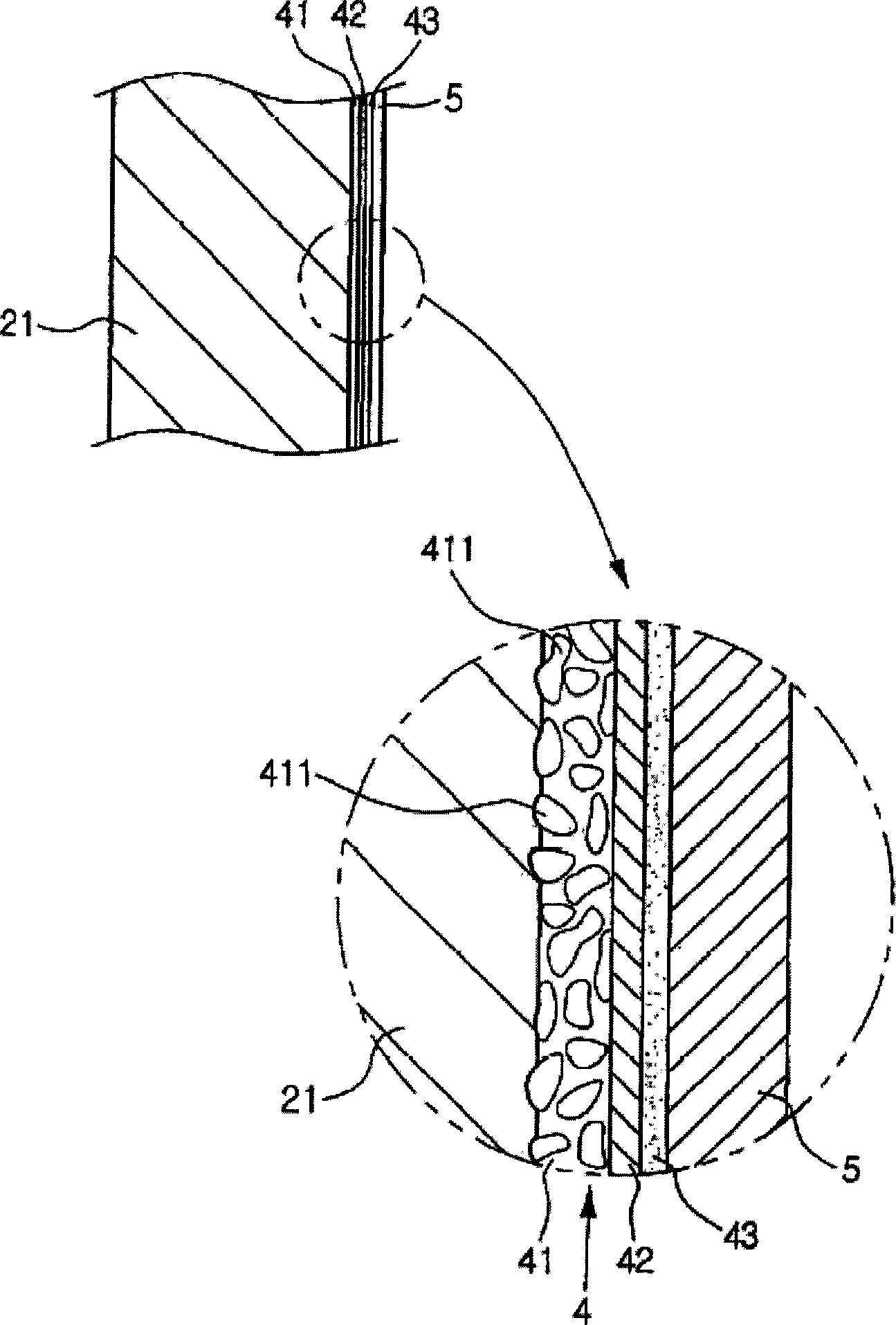

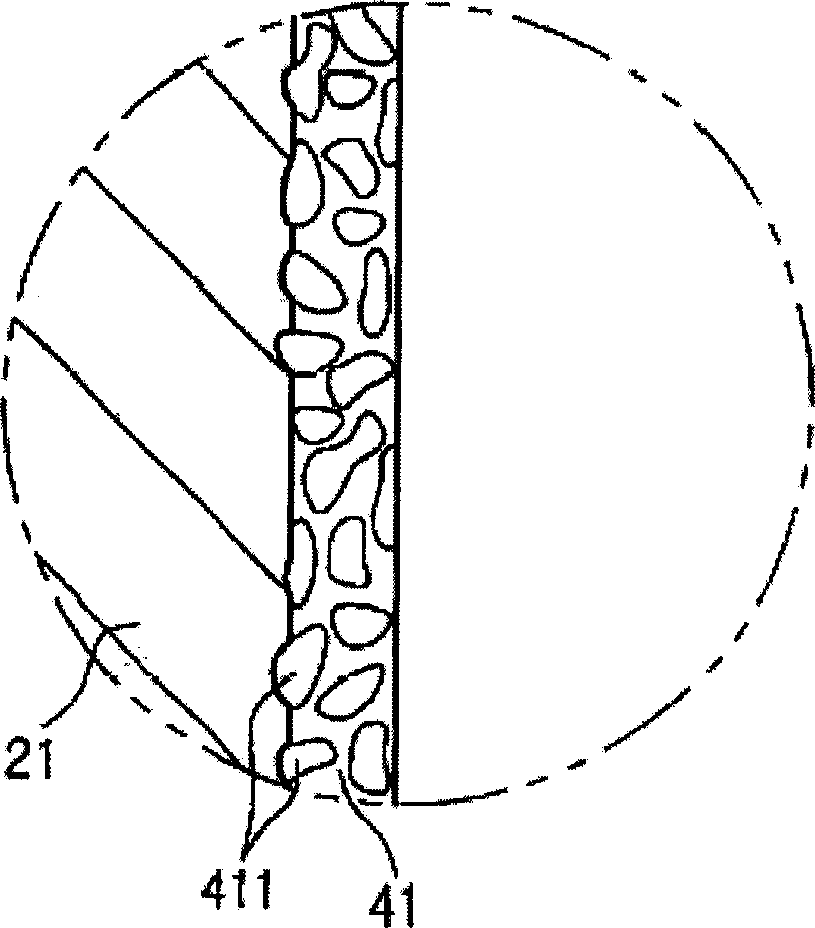

[0035] The loess urns include: basic inner and outer loess urns 1, 2, which include a pair of bodies 11, 21 and lids 12, 22, and these bodies 11, 21 and lids 12, 22 are china, the china Fired at 600-850 degrees with the following conditions: inner loess urn inserted into outer loess urn; and charcoal layer 3, which is stacked between inner loess urn and outer loess urn; adhesion layer 4 , which is formed on the surface of the outer loess urn 2 to stick to the board inlaid with mother-of-pearl, thus reinforcing the loess wall and smoothing the surface of the loess wall; and the traditional board, which is inlaid with mother-of-pearl 5, and the pearl The mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com