Hydraulic tension apparatus

A tensioning device, hydraulic technology, used in the direction of household components, flat products, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

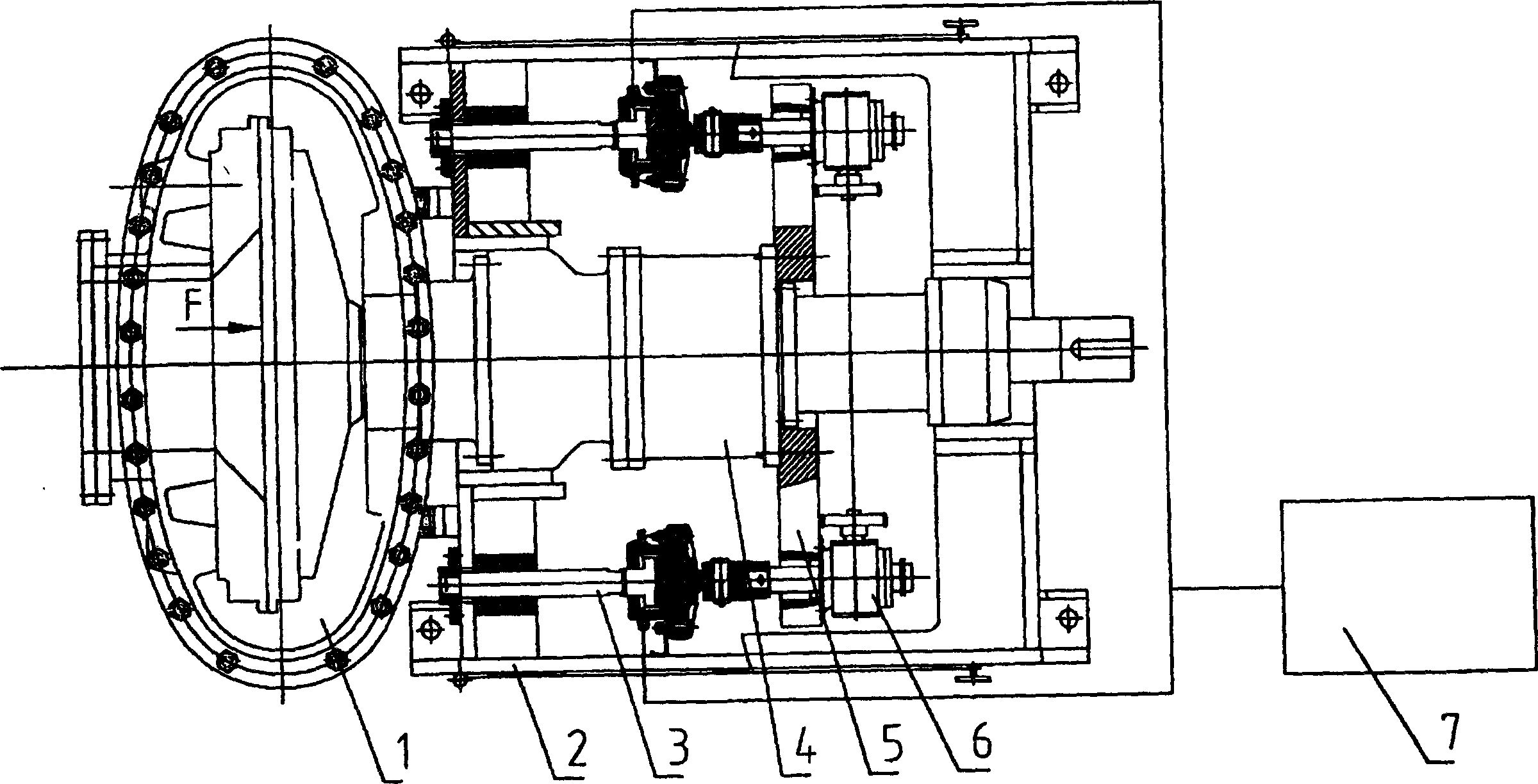

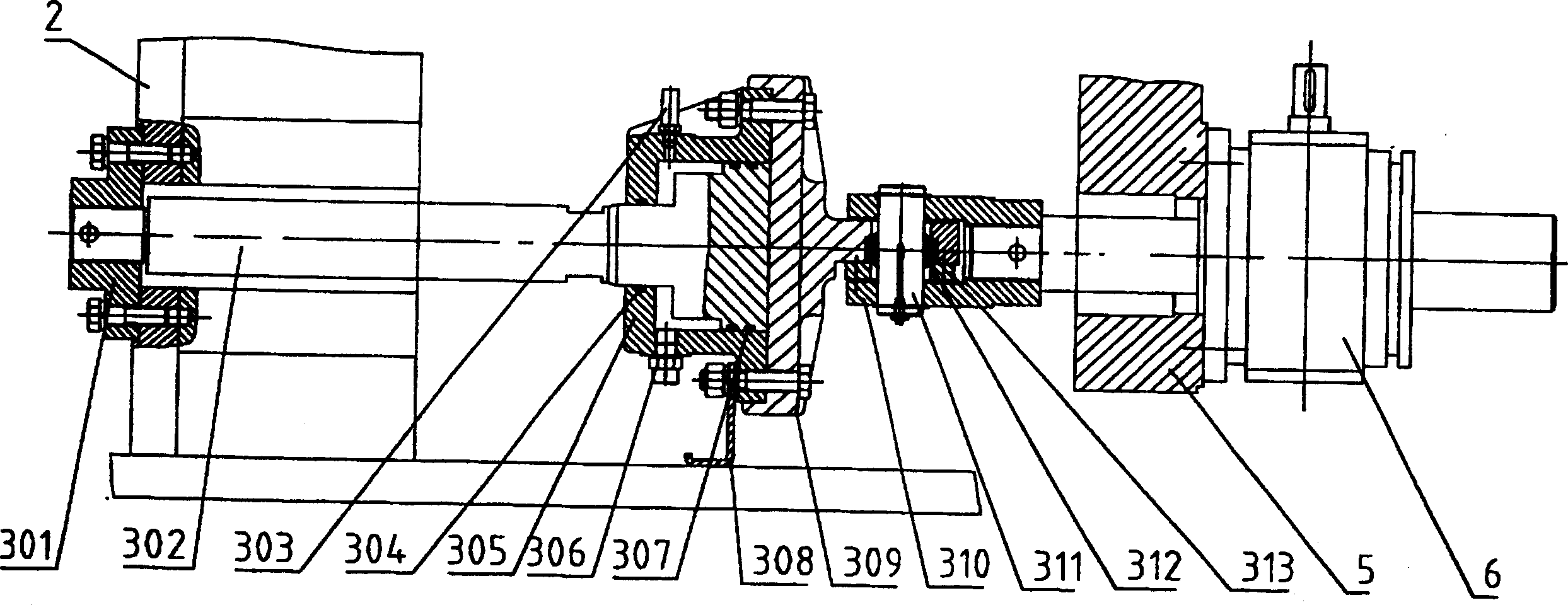

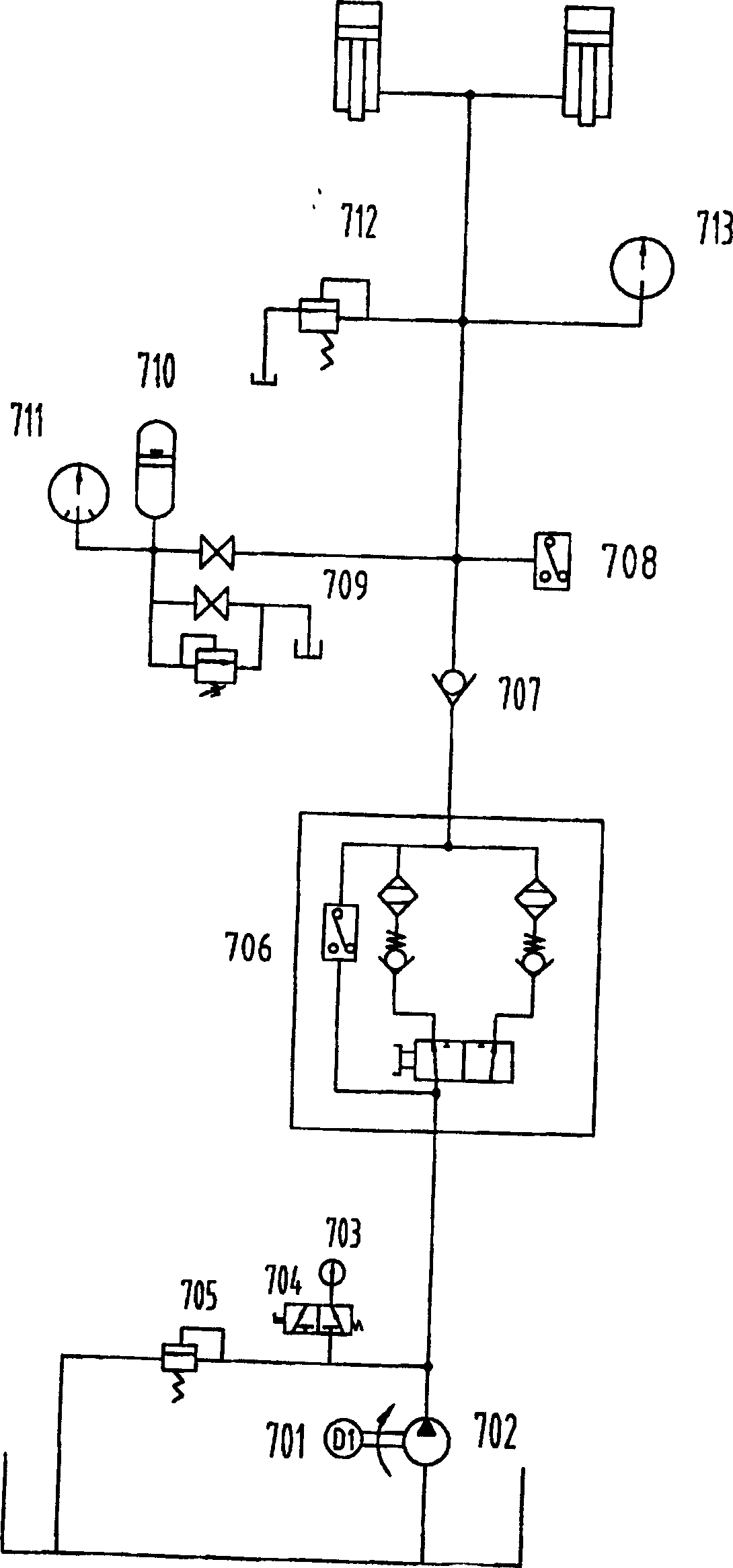

[0029] A wood-based panel fiber heat refiner with a production capacity of 15 tons per hour, which consists of figure 1 , figure 2 and image 3 The other components shown are the main shaft system 4 with a 1.4-meter-diameter main engine rotating grinding disc fixedly connected to the adjustment mechanism mounting plate 5 by bolts, and placed in the frame 2 to slide left and right. The right end of the main shaft system 4 is connected to the power source (3500KW, 1500 revolutions per minute motor), two hydraulic locking devices 3 are arranged on both sides of the main shaft system 4 respectively, and the exhaust pressure measuring joint 303, O-ring a 304, box body 305, oil inlet Mouth 306, O-ring b 307, anti-rotation lever 308, case cover 309, connecting rod 310, garden column pin 311, joint bearing 312, baffle plate 313, adjustment mechanism mounting plate 5 and adjustment mechanism driving device 6 press figure 2 It is required to be assembled into a whole, and the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com