Spiral-skeleton self-bearing type multi-core cable

A multi-core cable, self-supporting technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of not easy to bend, the center of gravity does not coincide, and the weight is large, and achieve the effect of high degree of freedom, uniform force and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

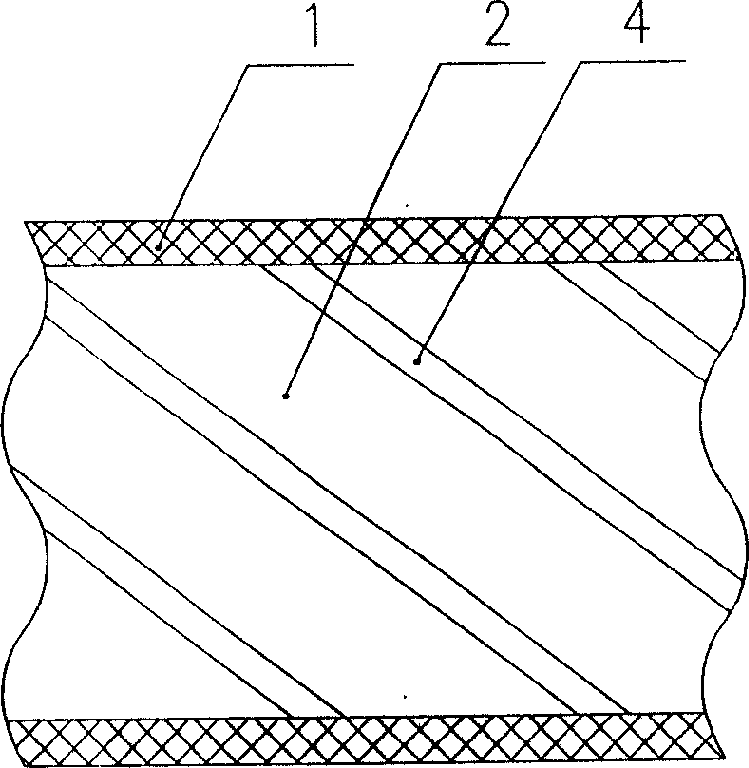

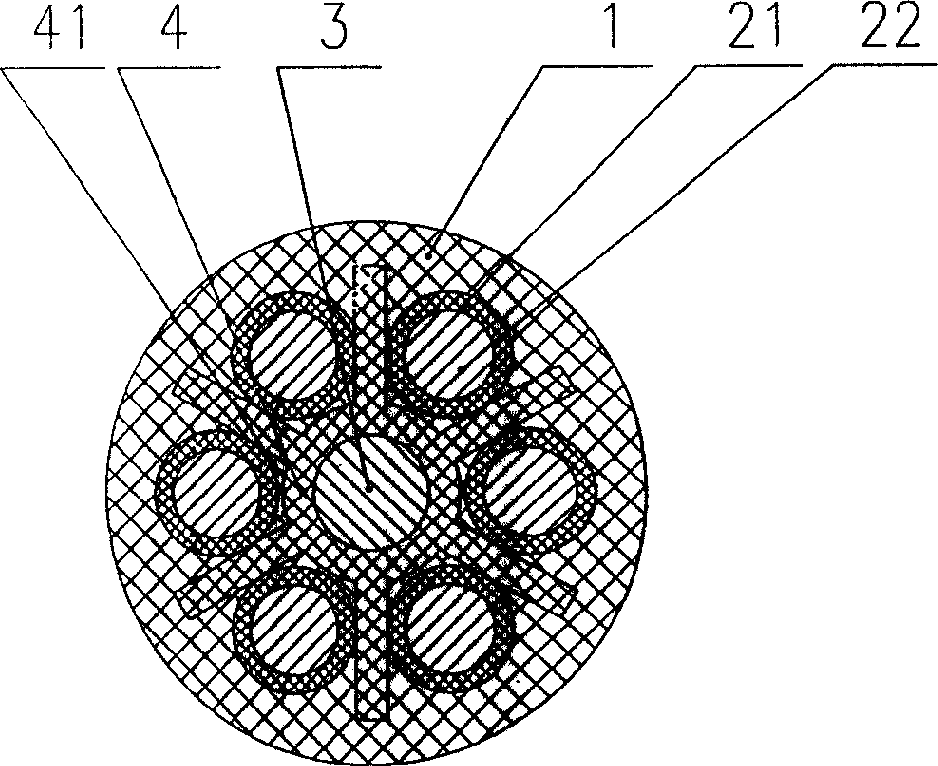

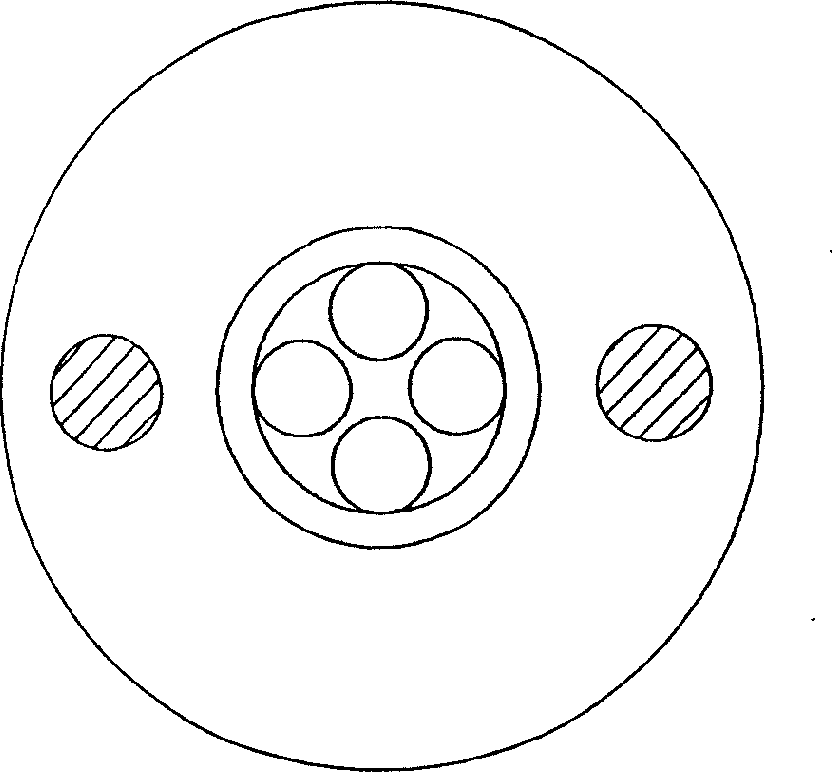

[0018] Such as figure 1 , figure 2 The spiral skeleton self-supporting multi-core cable shown has a cable outer sheath 1, and the materials used for the cable outer sheath 1 are PU, PVC, and TPE. According to requirements, the cable outer sheath 1 is provided with six insulated wires 2, and the insulation Conductive wire 2 is made up of multi-strand metal material conductive wire core 22 and insulated wire insulation layer 21 covering it, and multi-strand metal material conductive wire core 22 has relatively high conductivity, which can be silver wire, copper wire, aluminum wire, plated Silver copper wire, tinned copper wire, insulated wire insulation layer 21 use material is PVC, PE, PET, PU, multi-strand metal material conductive wire core 22 and insulated wire insulation layer 21 are assembled into one with extruder. The center of the cable outer sheath 1 is provided with a spiral skeleton 4, and the center of the spiral skeleton 4 is provided with a strong rope 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com