Endless belt and method of manufacturing endless belt

A manufacturing method and a technology of an endless belt, applied to chemical instruments and methods, belts, and other household appliances, etc., can solve problems such as loss of elasticity, hardening of silicone rubber, etc., and achieve the effects of preventing wrinkles, dimensional stability, and excellent fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

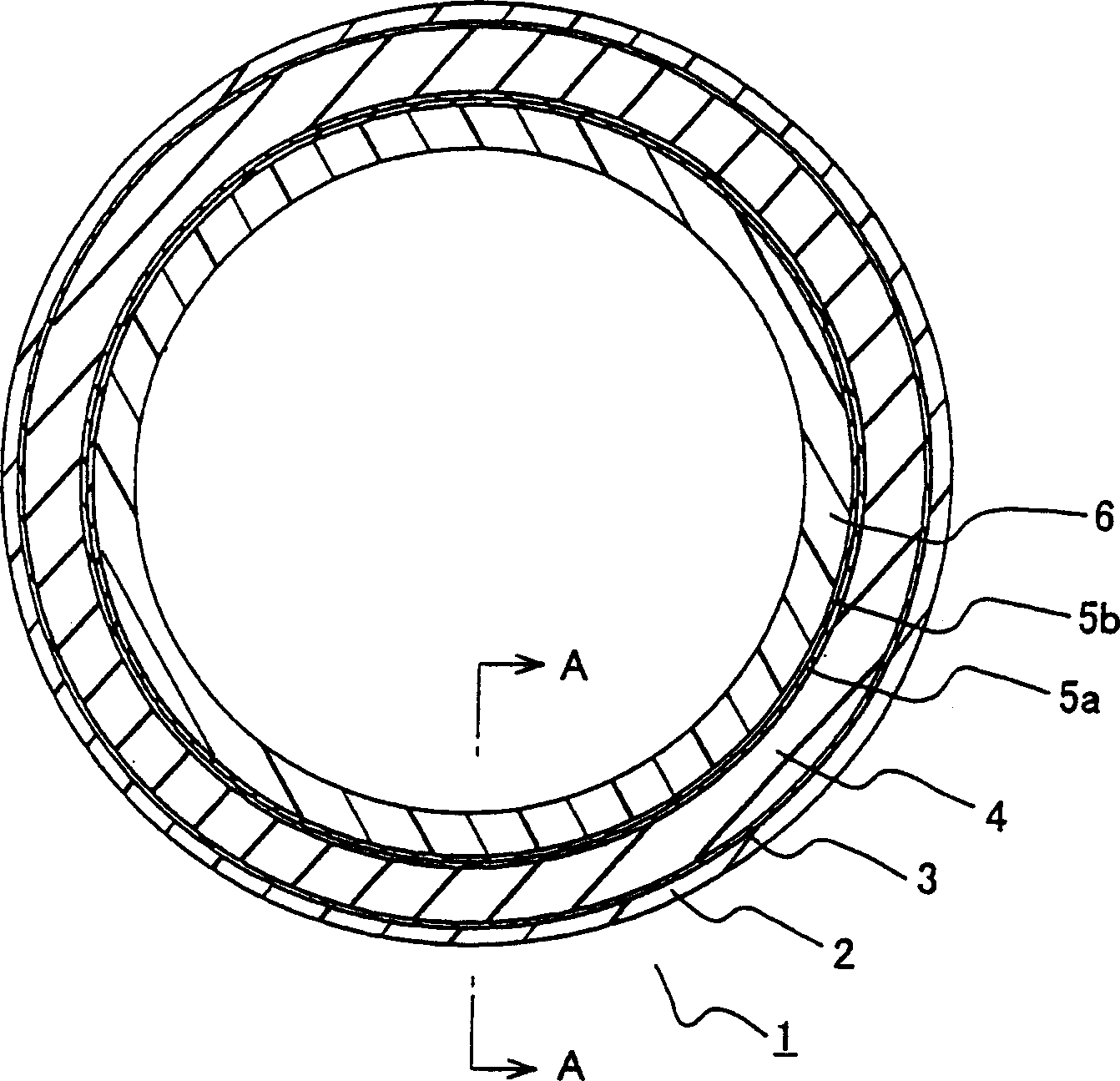

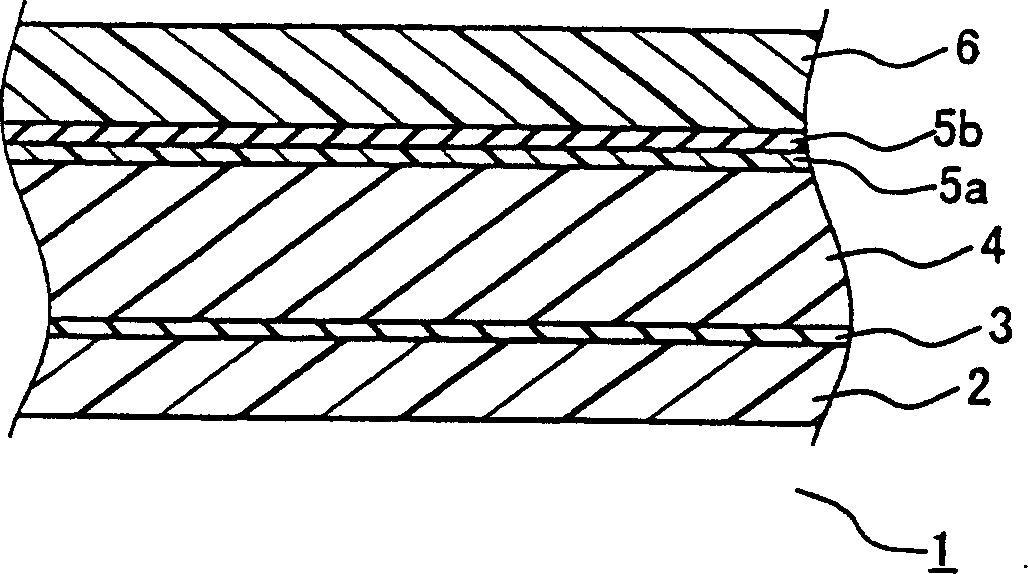

[0034] figure 1 is a cross-sectional view of an annulus according to the invention, figure 2 Yes figure 1 A sectional view of the main part at the A-A plane in . The endless belt 1 according to the present invention includes: a release layer 2 as the outermost layer, which is formed of fluororesin, and whose outer surface is constituted by a molding surface; a first adhesive layer 3, which is arranged following the release layer 2 ; an elastic layer 4, which follows the first adhesive layer 3; a second adhesive layer consisting of two layers 5a and 5b, which follows the elastic layer 4; and a support layer 6 as the innermost layer, which Follow layer 5b settings. In other words, the endless belt according to the present invention is an endless belt having the following layers: a release layer 2 as the outermost layer of the endless belt 1, which is formed of fluororesin and has an outer surface composed of a molding surface; a support layer 6; and an elastic layer 4 as an...

Embodiment approach 2

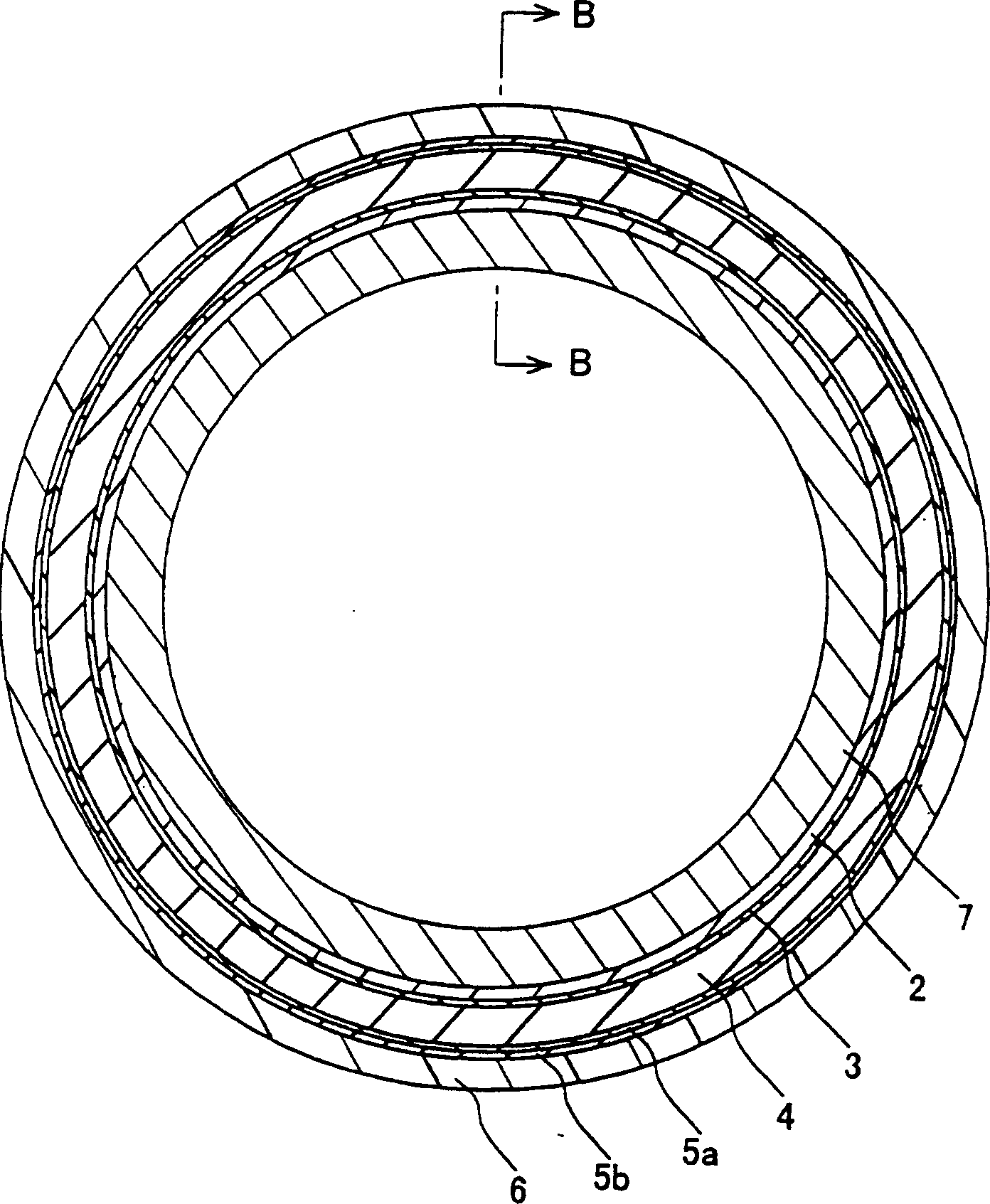

[0056] image 3 is a sectional view for explaining a method of manufacturing an endless belt according to the present invention, Figure 4 Yes image 3 A cross-sectional view of the main part at the B-B plane. The manufacturing method of the endless belt according to the present invention comprises: a release layer 2 made of fluororesin is coated on the outer peripheral surface of the ring forming mold 7; a first bonding layer 3 is coated on the release layer 2; Afterwards, these layers are baked at a given temperature; Afterwards, an elastic layer 4 is coated on the first bonding layer 3 and is baked at a given temperature; Afterwards, a bonded by two A second adhesive layer composed of layers 5a and 5b is applied on the elastic layer 4 and dried; after that, a support layer 6 is applied on the layer 5b in the second adhesive layer and heated at a given temperature to be baked. Next, if Figure 5 As shown, the endless belt 1 is separated from the forming mold 7 by being ...

Embodiment approach 3

[0065] A method for manufacturing an endless belt according to the present invention includes: a release layer made of fluororesin is coated on the outer peripheral surface of the ring forming mold and baked at a given temperature; after that, the release layer The surface is etched; after that, an elastic layer is coated on the etched surface of the release layer and baked at a given temperature; after that, an adhesive layer is coated on the elastic layer and dried; after that , a support layer is coated on the bonding layer and baked at a given temperature. Next, in the same manner as in Embodiment Mode 2, the endless belt is separated from the molding die by being turned inside out and pulled down. In this way, an endless belt according to the present invention is completed, comprising: a release layer as the outermost layer of the endless belt, which is formed of fluororesin and has an outer surface composed of a molding surface; layer; and an elastic layer as an interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com