Functional material fixing method and functional material fixing device

A technology of functional materials and fixing methods, applied in printing devices, lighting devices, optical/shielding devices, etc., can solve problems such as wiring disconnection, drying step taking a long time, reference line offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

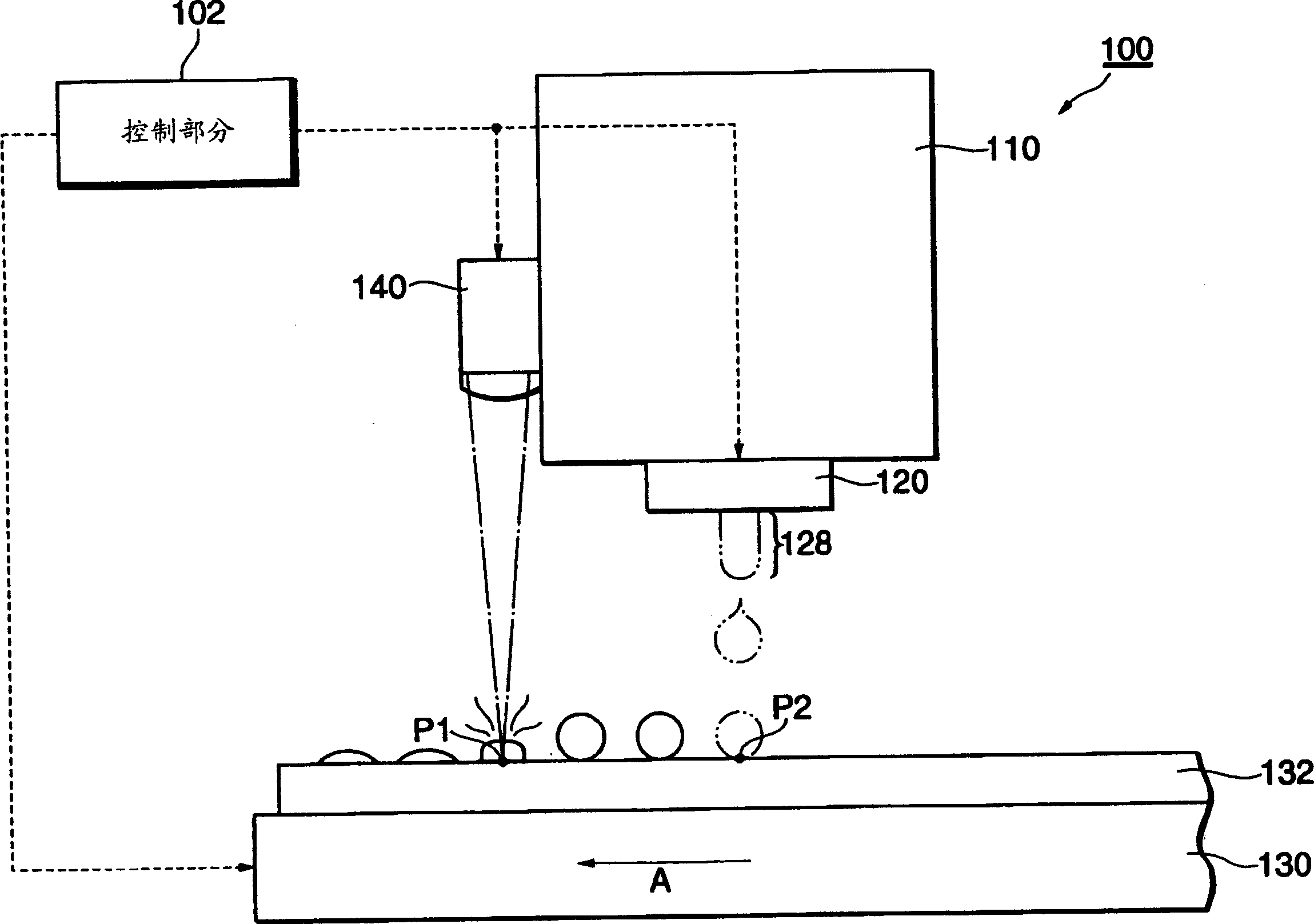

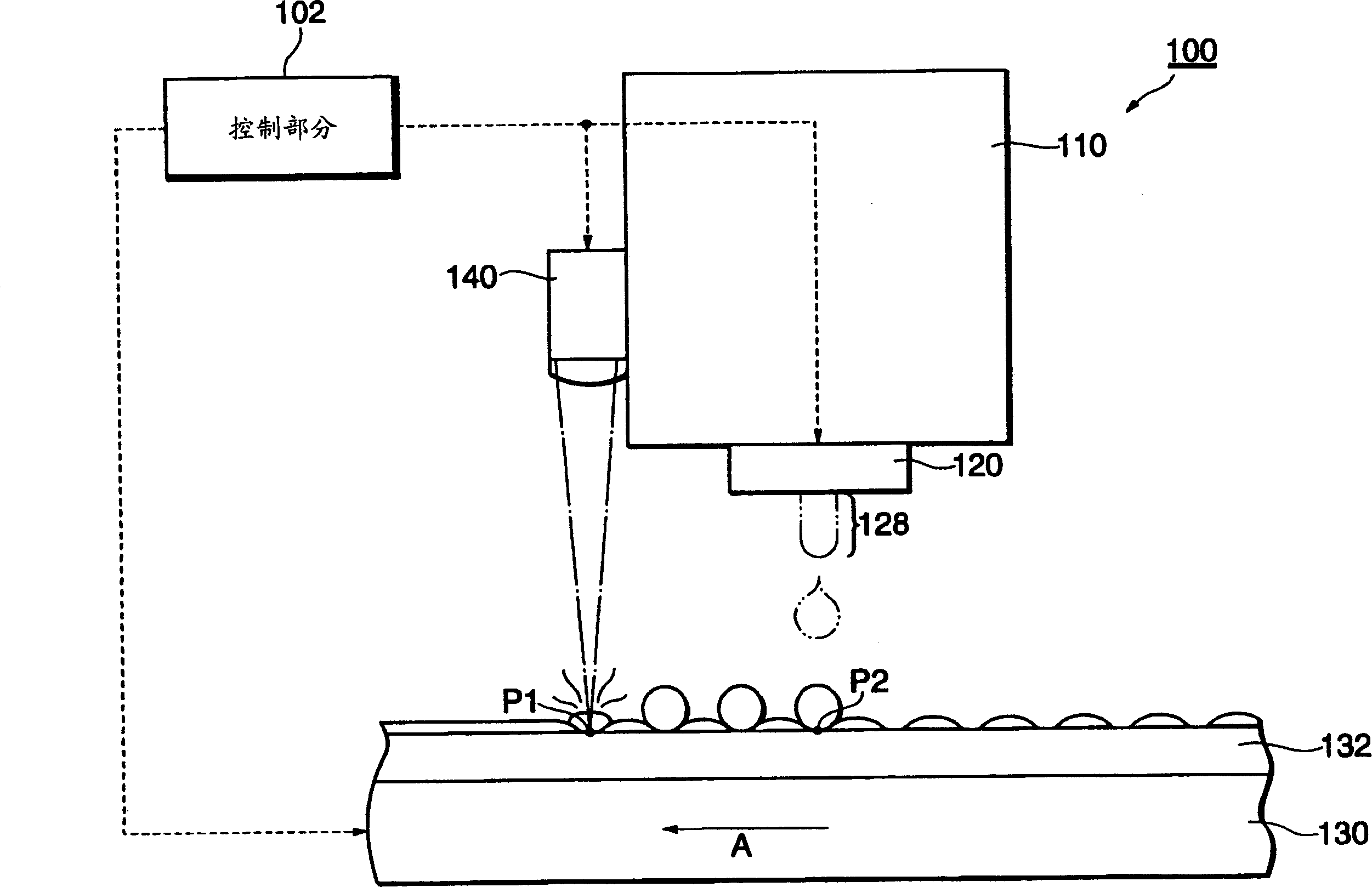

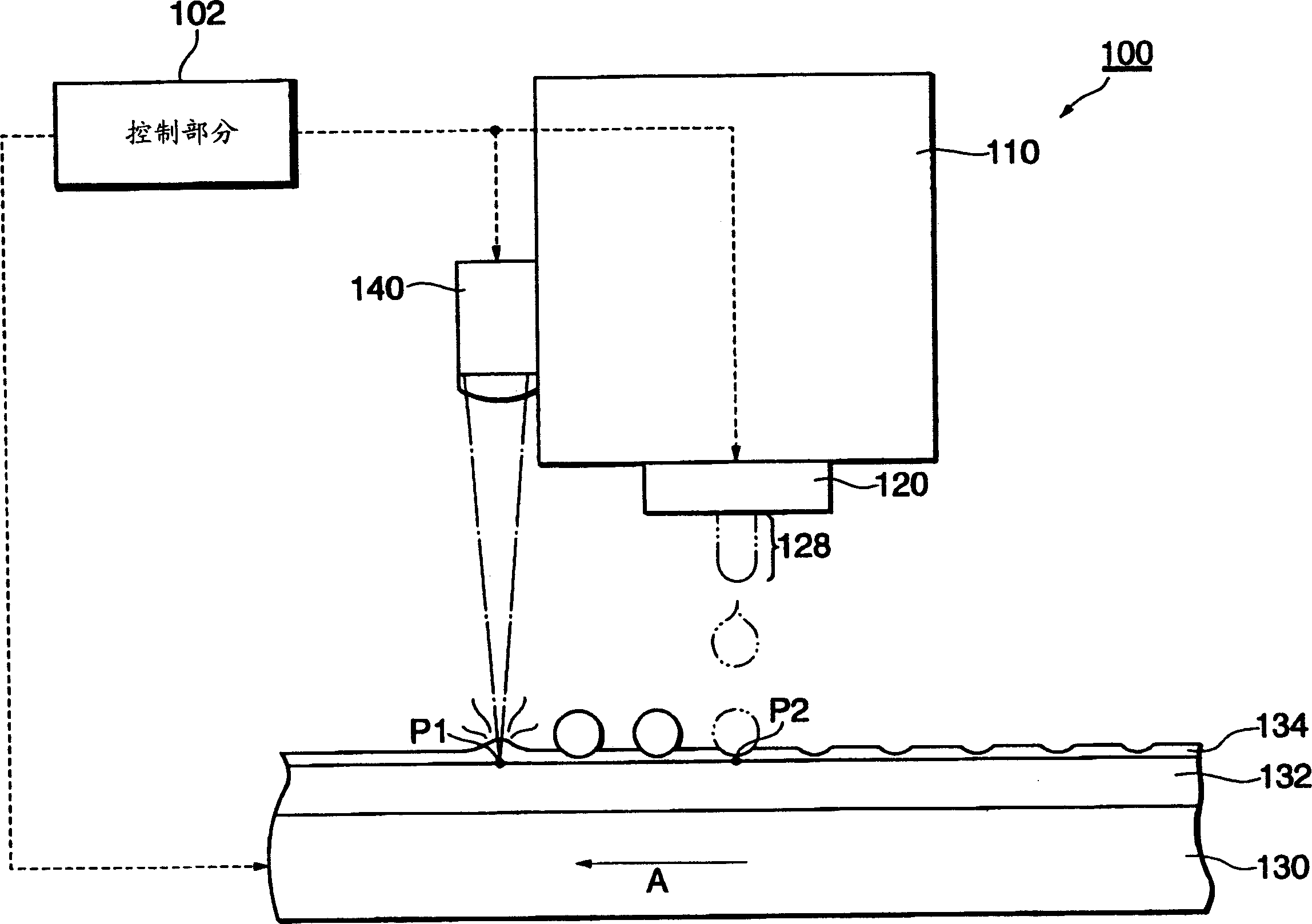

[0075] figure 1 It is a schematic diagram of the structure of the functional material fixing device 100 of the first embodiment.

[0076] According to the figure, the control unit 102 outputs drive signals to the ejection head 120, the base carriage 130, the laser source 140, and the actuator 170 to control the entire system. The control section 102 includes a CPU, a timer, a memory storing wiring patterns, and the like. The solution container 110 stores a solution with a viscosity of 20mpa·s, which is mixed with silver particles constituting the wiring material in C 14 h 30 (n-tetradecane: n-tetradecane) and other organic solutions (solvents). The ejection head 120 receives the solution supplied from the solution container 110 under the control of the control unit 102 , and ejects the solution into droplets.

[0077] The substrate carrier 130 transfers the substrate 132 in a horizontal direction corresponding to the ejection head 120 under the control of the control part ...

Embodiment 2

[0092] According to the first embodiment, the functional material fixing device 100 for immobilizing the liquid droplets by irradiating the liquid droplets with a low-intensity laser after applying them has been described. On the other hand, according to the second embodiment, a functional material fixing device that irradiates the droplet with laser light almost simultaneously with the application of the droplet to fix the droplet will be described. Among the configurations of the functional material fixing device of this embodiment, the same configurations as those of the above-mentioned first embodiment are denoted by the same symbols.

[0093] Figure 4 It is a schematic diagram of the structure of the functional material fixing device 200 of the second embodiment. As shown in the figure, compared with the functional material fixing device 100 of the first embodiment, this device 200 newly adds a reflector 180 on the optical path of the laser light. The reflector 180 ref...

Embodiment 3

[0099] According to the above-mentioned first embodiment, the functional material fixing device 100 for fixing the functional material by scanning the substrate 132 with respect to a set of the ejection head 120 and the laser light source 140 has been described. On the other hand, according to the third embodiment, a functional material fixing device that scans a substrate 132 with respect to two sets of jet heads and laser light sources will be described.

[0100] Figure 7 It is a schematic diagram of the structure of the functional material fixing device 300 of the third embodiment. As shown in the figure, this apparatus 300 includes a solution container 110 a located upstream in the transport direction A of the substrate and a solution container 110 b located downstream. Wherein, the solution container 110a is equipped with a spray head 120a and a laser source 140a. On the other hand, the solution container 110b is equipped with an ejection head 120b and a laser light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com