Hydraulic bearing, main shaft motor with said hydraulic bearing and disc driver with said main shaft motor

一种液动、轴承的技术,应用在带有静止电枢和旋转磁体的同步电动机、机电装置、滑动接触轴承等方向,能够解决外部助振力耐性不足等问题,达到防止保持量不足、扩大适用范围、强化耐性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

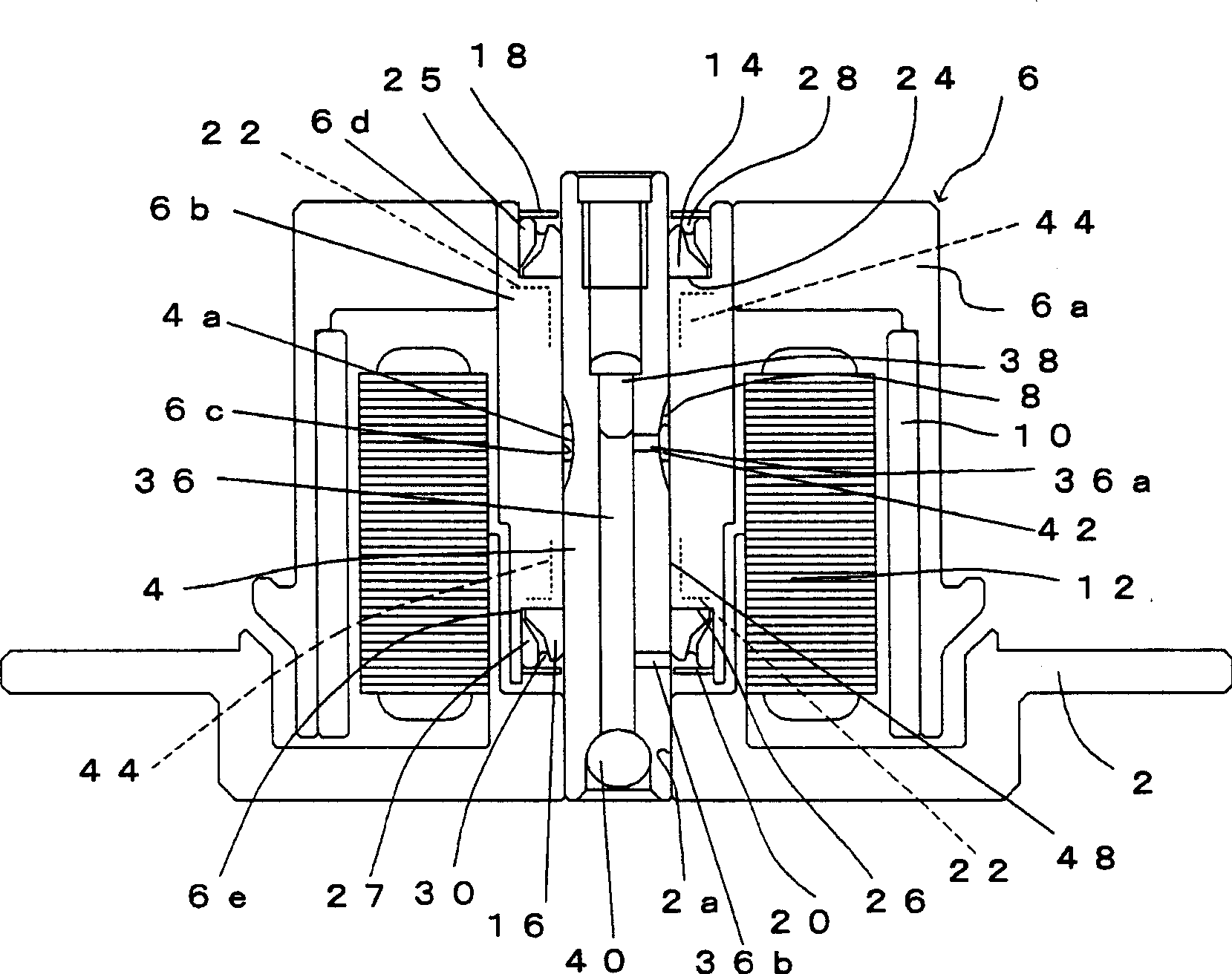

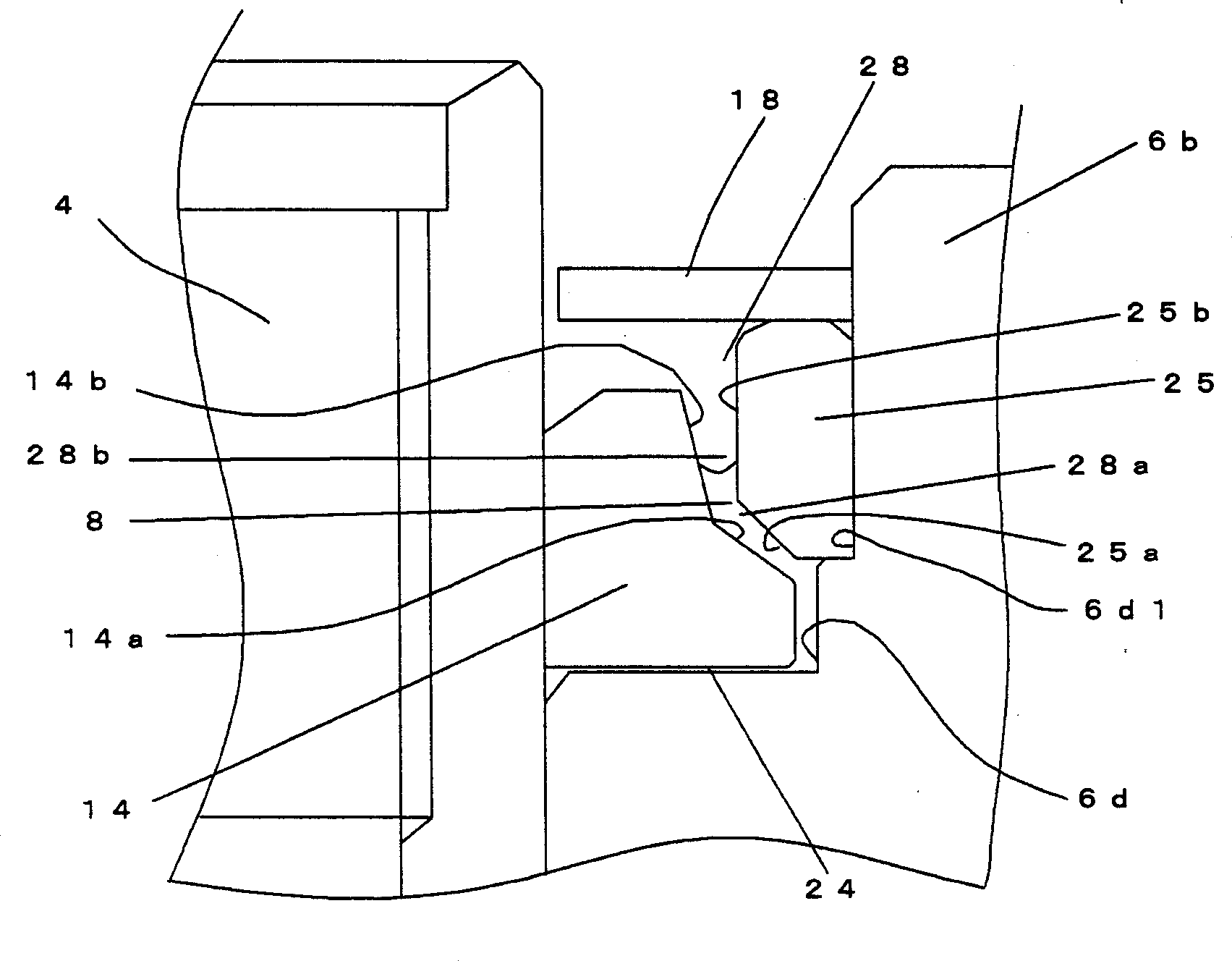

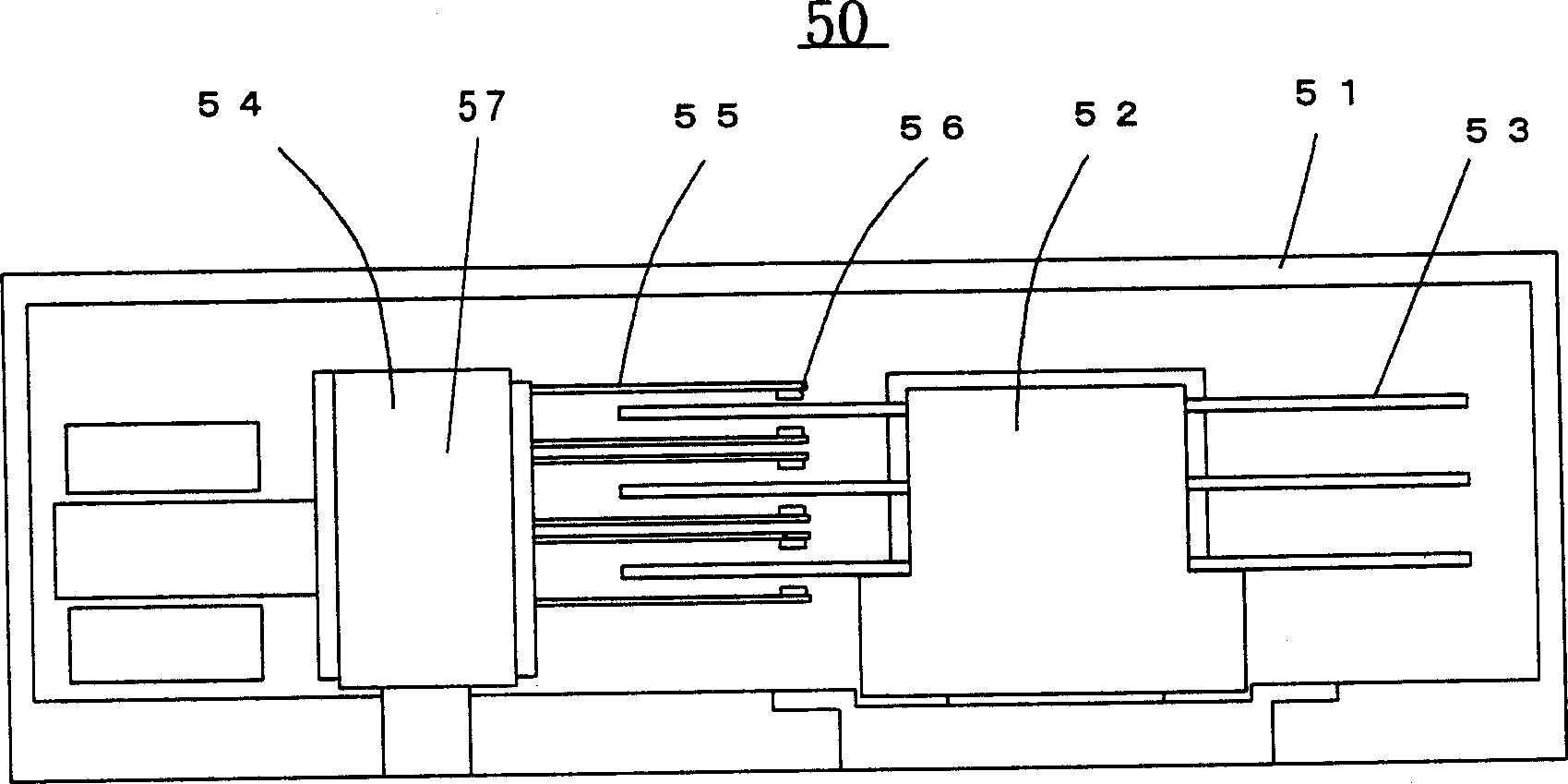

[0026] Below, refer to Figure 1 to Figure 3 ,and Figure 5 One embodiment of the fluid dynamic bearing of the present invention, a spindle motor using the fluid dynamic bearing, and a disk drive device including the spindle motor will be described. In addition, in one embodiment described in the present invention, the up-down direction in each drawing is referred to as "up-down direction" for convenience, but it is not used to limit the direction in the actual installation state.

[0027] figure 1 The shown spindle motor has: a bracket 2; a shaft 4 fixed on the bracket 2; a rotor 6 supported by the shaft 4 through a hydrodynamic bearing and relatively freely rotatable.

[0028] In the center of the bracket 2 as a stationary member, a center hole 2a in which one end of the shaft 4 is fitted and fixed is formed.

[0029] The rotor 6 as a rotating member includes: a sleeve 6b facing the shaft 4 via a hydrodynamic bearing; and a rotor hub 6a fitted and fixed to the outer peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com