Electron emitter and method for fabricating the same, cold cathode field electron emission element and method for fabricating the same, and cold cathode field electron emission display and method

A field electron emission and electron emitter technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the growth obstruction of carbon nanotube structures and the electron emission efficiency of carbon nanotube structures decline, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Embodiment 1 relates to the electron emitter of the present invention, the manufacturing method of the electron emitter related to the first embodiment of the present invention, the cold cathode field electron emission device (hereinafter referred to simply as the field emission device) of the first embodiment and its manufacturing method And the so-called two-electrode type cold cathode field electron emission display device of the first form (hereinafter, simply referred to as a display device) and its manufacturing method also relate to a first method.

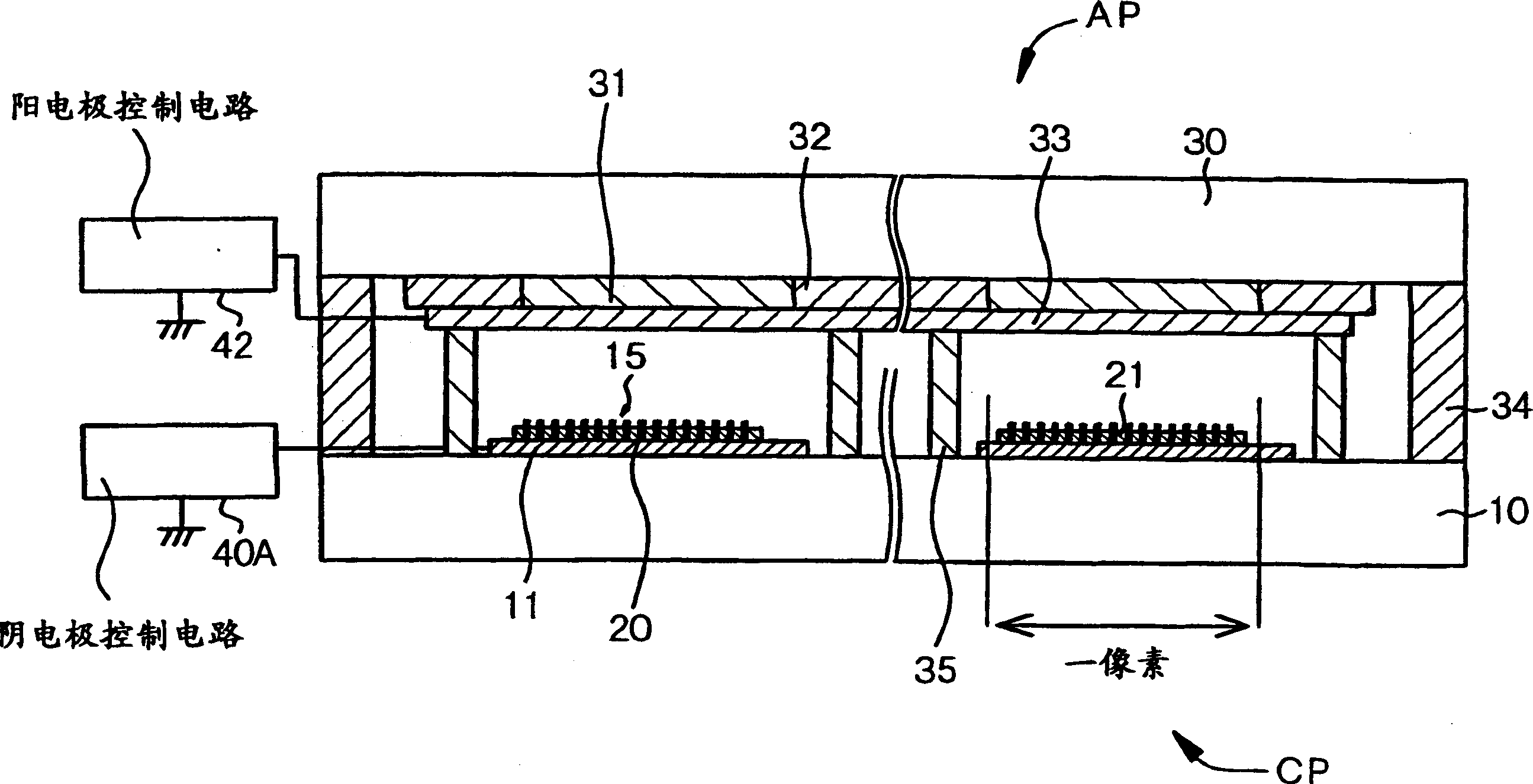

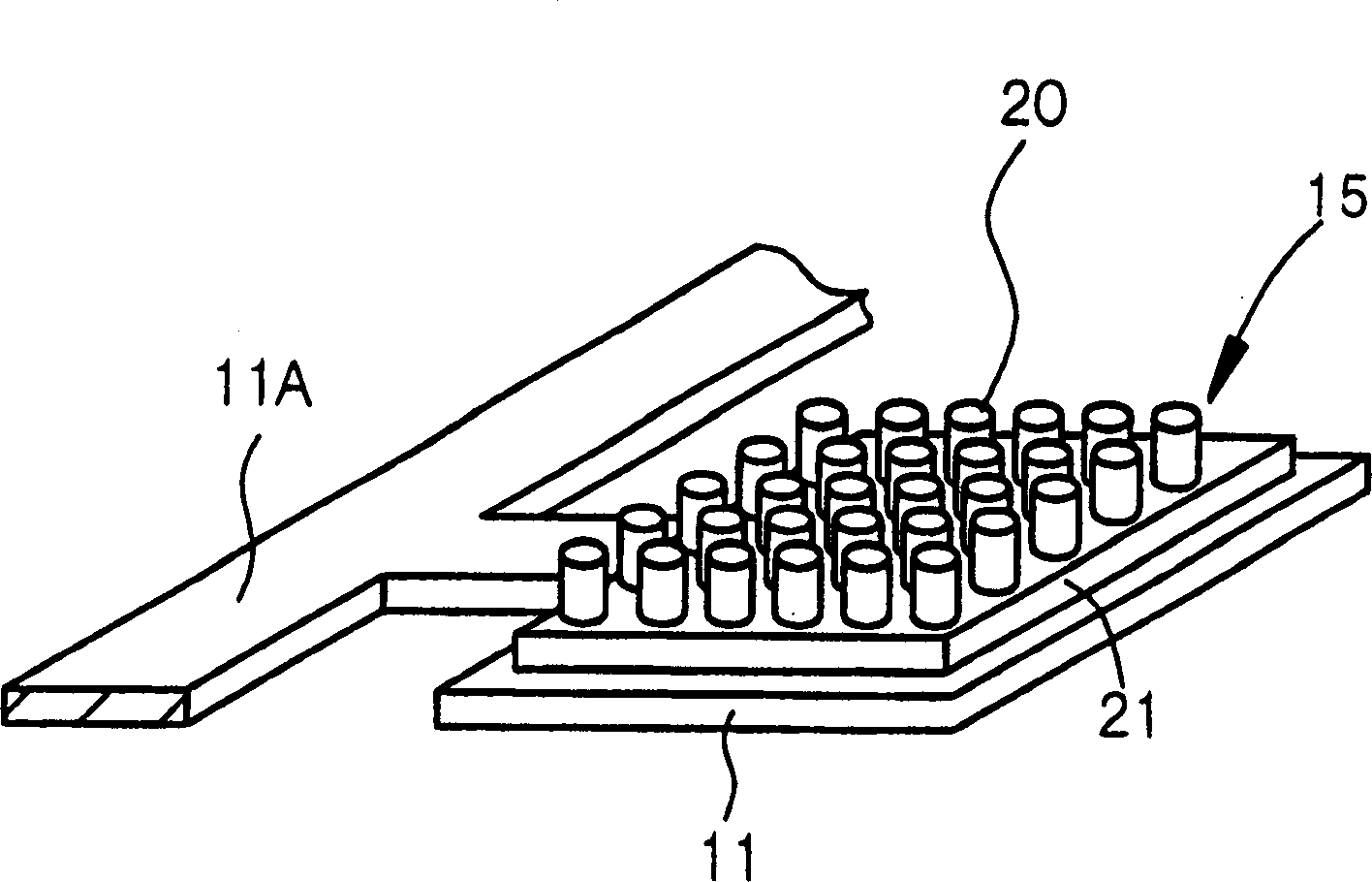

[0124] figure 1 A schematic cross-sectional view of a part of the display device in Example 1 is shown, figure 2 A schematic perspective view of an electron-emitting portion is shown, and (B) of FIG. 4 shows a schematic cross-sectional view of a part of an electron-emitting portion.

[0125] The electron emitter in Example 1 is composed of a matrix 21 and a carbon nanotube structure embedded in the matrix 21 with i...

Embodiment 2

[0178] Embodiment 2 relates to the electron emitter of the present invention, the manufacturing method of the electron emitter of the first aspect of the present invention, the field emission device of the second aspect and its manufacturing method, and the so-called three-electrode display device of the second aspect and its manufacturing method. The manufacturing method also relates to the first method.

[0179] (B) in FIG. 10 shows a partial schematic end view of the field emission device in Example 2, Figure 7 shows a partial schematic end view of the display device, Figure 8 It shows a partial schematic perspective view when the cathode panel CP and the anode panel AP are disassembled. This field emission component is made up of following parts: the negative electrode 11 (corresponding to substrate) that is formed on the support body 10; The insulating layer 12 that is formed on the support body 10 and the negative electrode 11; The gate electrode that is formed on the...

Embodiment 3

[0202] Embodiment 3 is a modified example of Embodiment 2. Embodiment 3 differs from Embodiment 2 in that carbon nanotubes are formed on the cathode electrode 11 (substrate) by plasma CVD. That is, Embodiment 3 is related to the second method. Hereinafter, a method of manufacturing an electron emitter, a method of manufacturing a field emission member, and a method of manufacturing a display device in Example 3 will be described with reference to (A) and (B) in FIG. 11 .

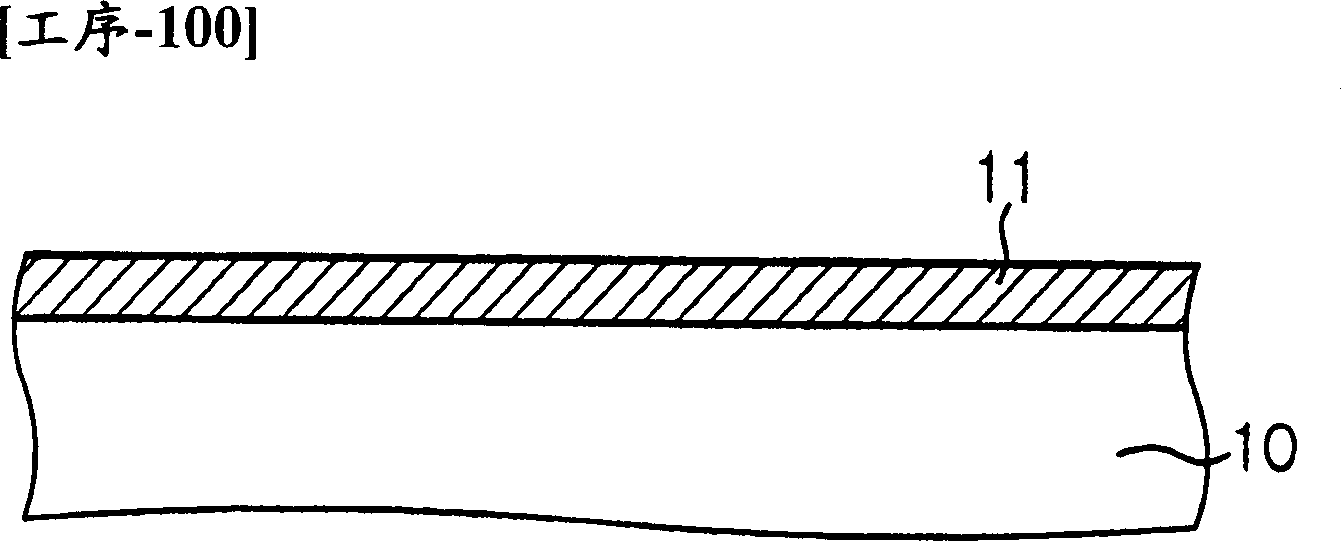

[0203] [Process-300]

[0204] First, the cathode electrode 11 on which the selective growth region 23 has been formed is formed in the surface region where the electron emission portion is to be formed. Specifically, a mask layer made of a resist material is formed on a support 10 made of, for example, a glass substrate. A mask layer is formed to cover the support 10 other than the portion where the stripe-shaped negative electrodes are to be formed. Next, after forming an aluminum (Al) layer over the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com