Mixed compressor

A compressor and hybrid technology, used in liquid variable capacity machinery, rotary piston machinery, mechanical equipment, etc., can solve problems such as mechanical damage and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

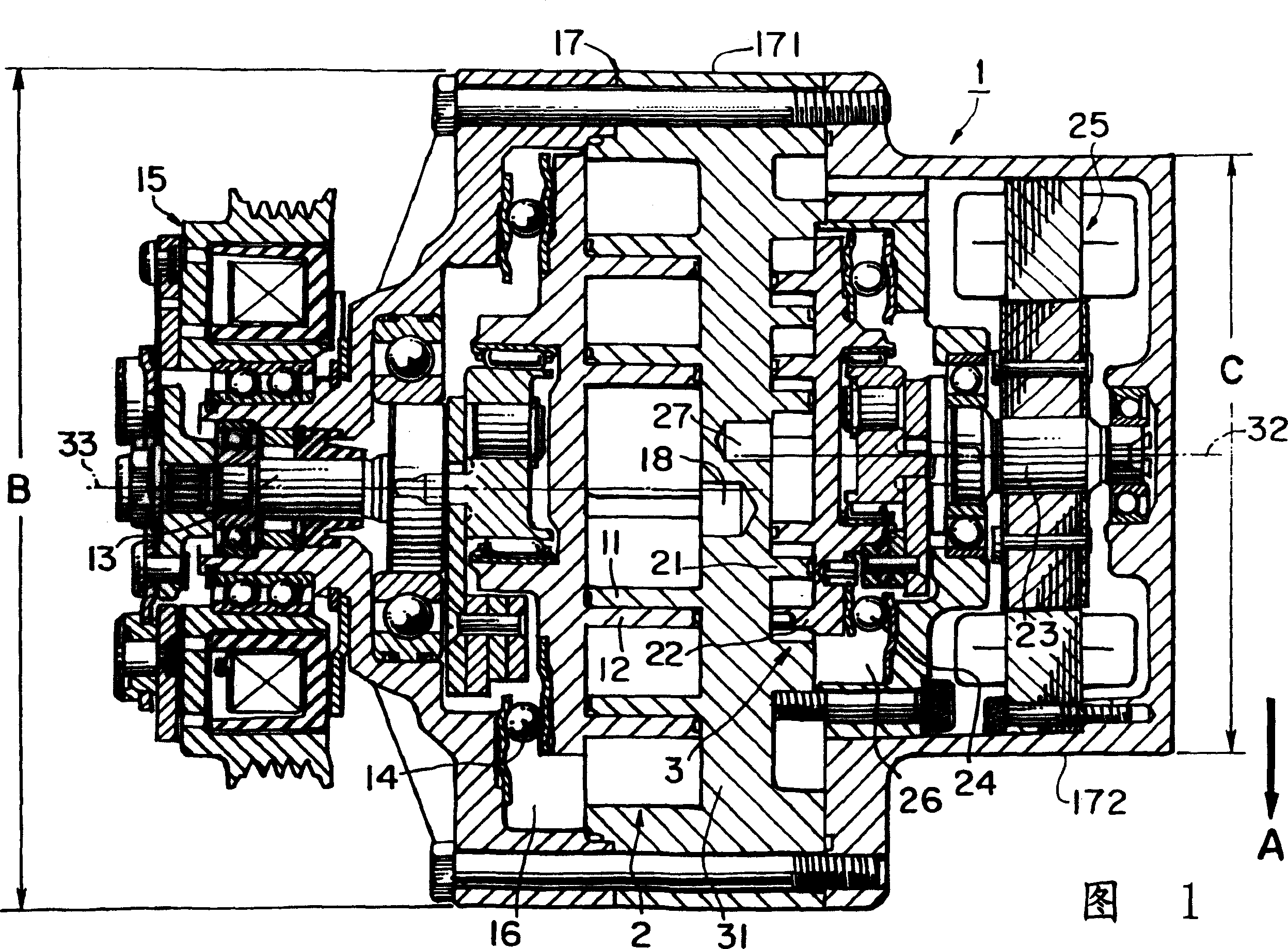

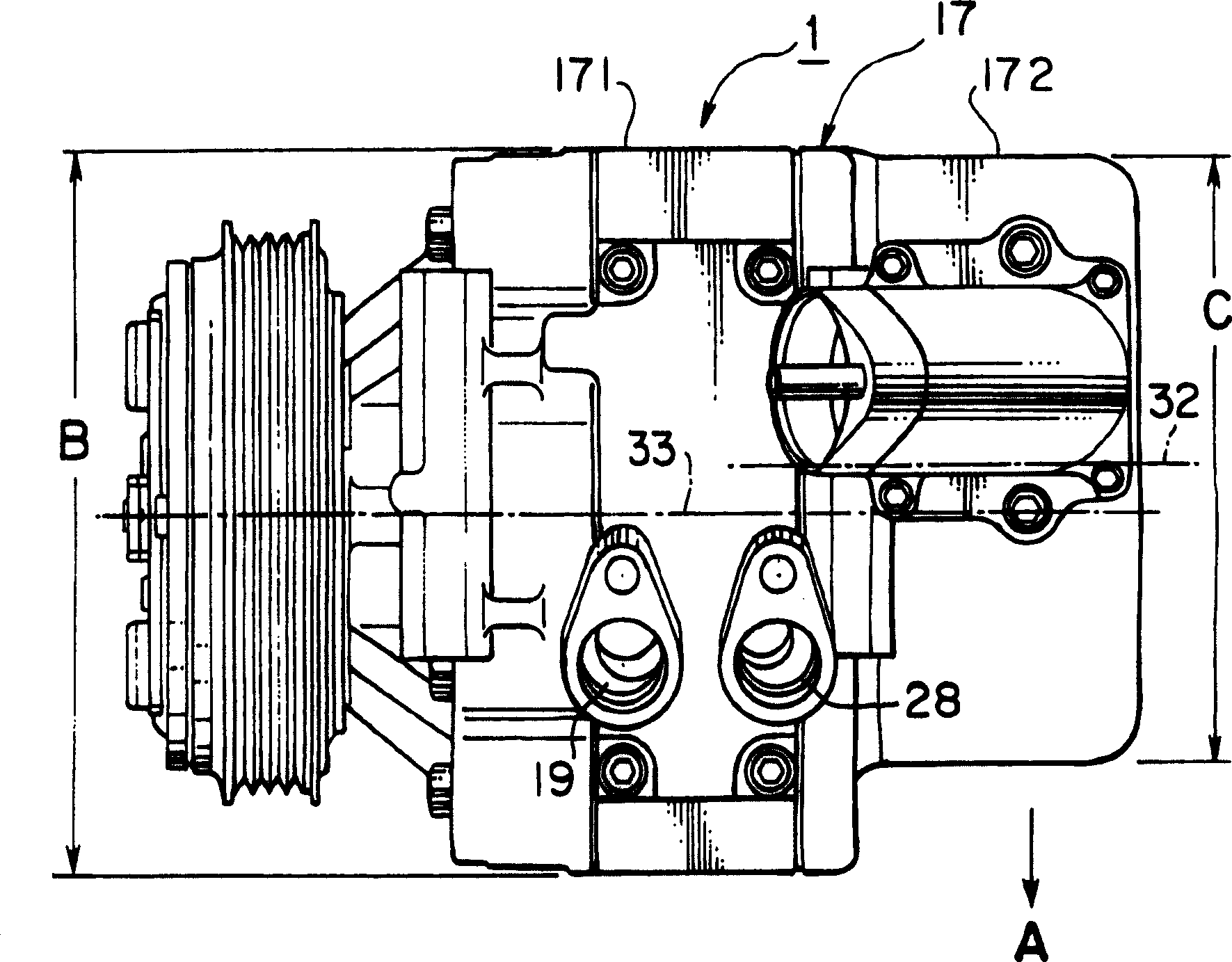

[0023] Figures 1 and 2 illustrate a hybrid compressor according to one embodiment of the present invention. This embodiment is a preferred embodiment in which the above-mentioned structures of the first and second hybrid compressors of the present invention are employed simultaneously. The hybrid compressor is used, for example, in a refrigeration cycle of an air-conditioning system installed in an automobile.

[0024] In Fig. 1, a hybrid compressor 1 includes a first compression mechanism 2 and a second compression mechanism 3, wherein the first compression mechanism is only driven by a first drive source (not shown) through an electromagnetic clutch 15, and the second compression mechanism The mechanism is driven only by the electric motor 25 installed inside as the second driving source. The first and second compression mechanisms 2 and 3 are arranged in the axial direction of the hybrid compressor 1 and they are integrally assembled with each other inside the compressor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com