Ink box filling machine for ink-jet recording equipment

An inkjet recording and filling machine technology, applied in printing and other directions, can solve problems such as damage, large error value, and affecting the quality of ink cartridges, and achieve the effect of prolonging the service life and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

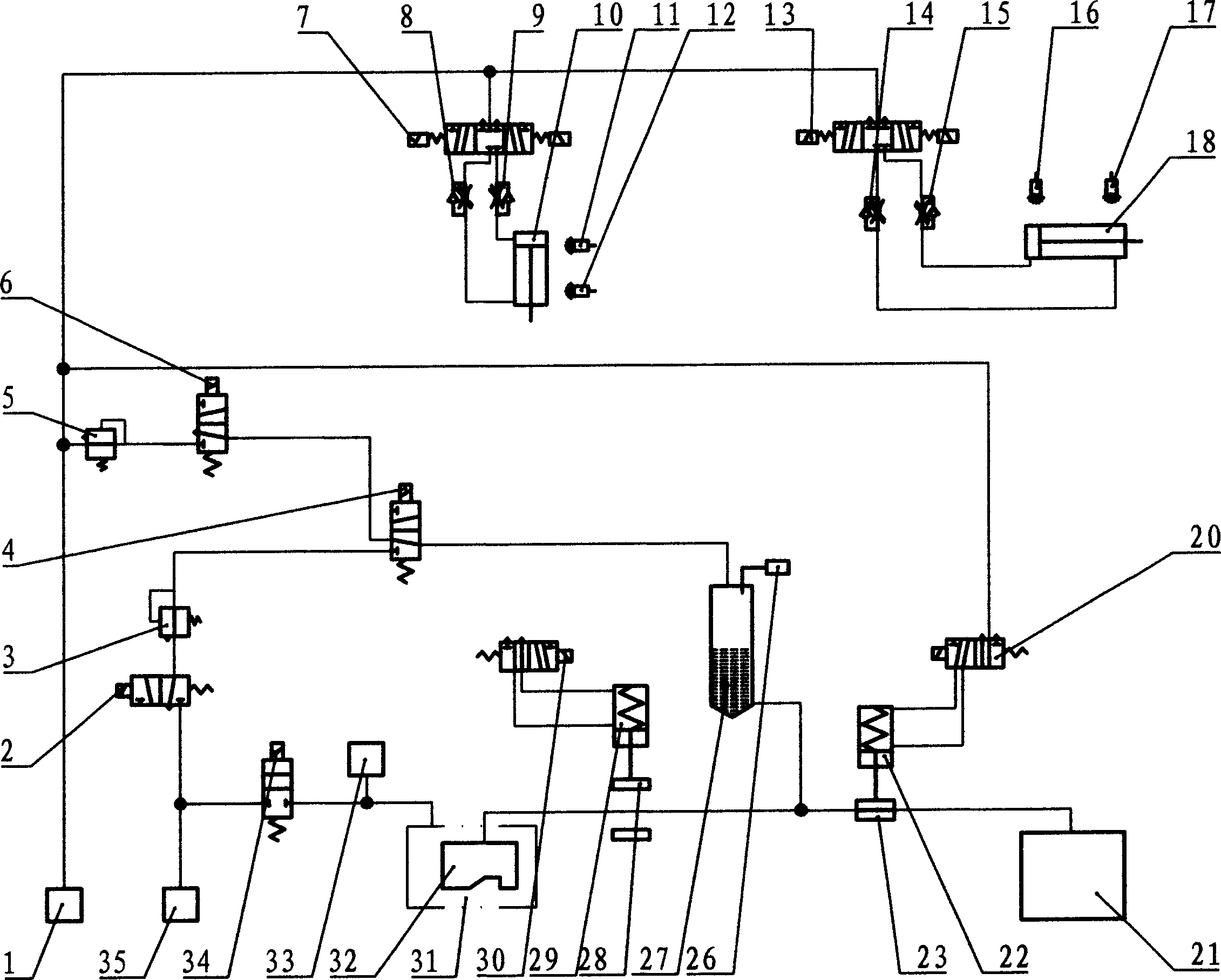

[0020] see figure 1 , where the parts represented by each part number are as follows:

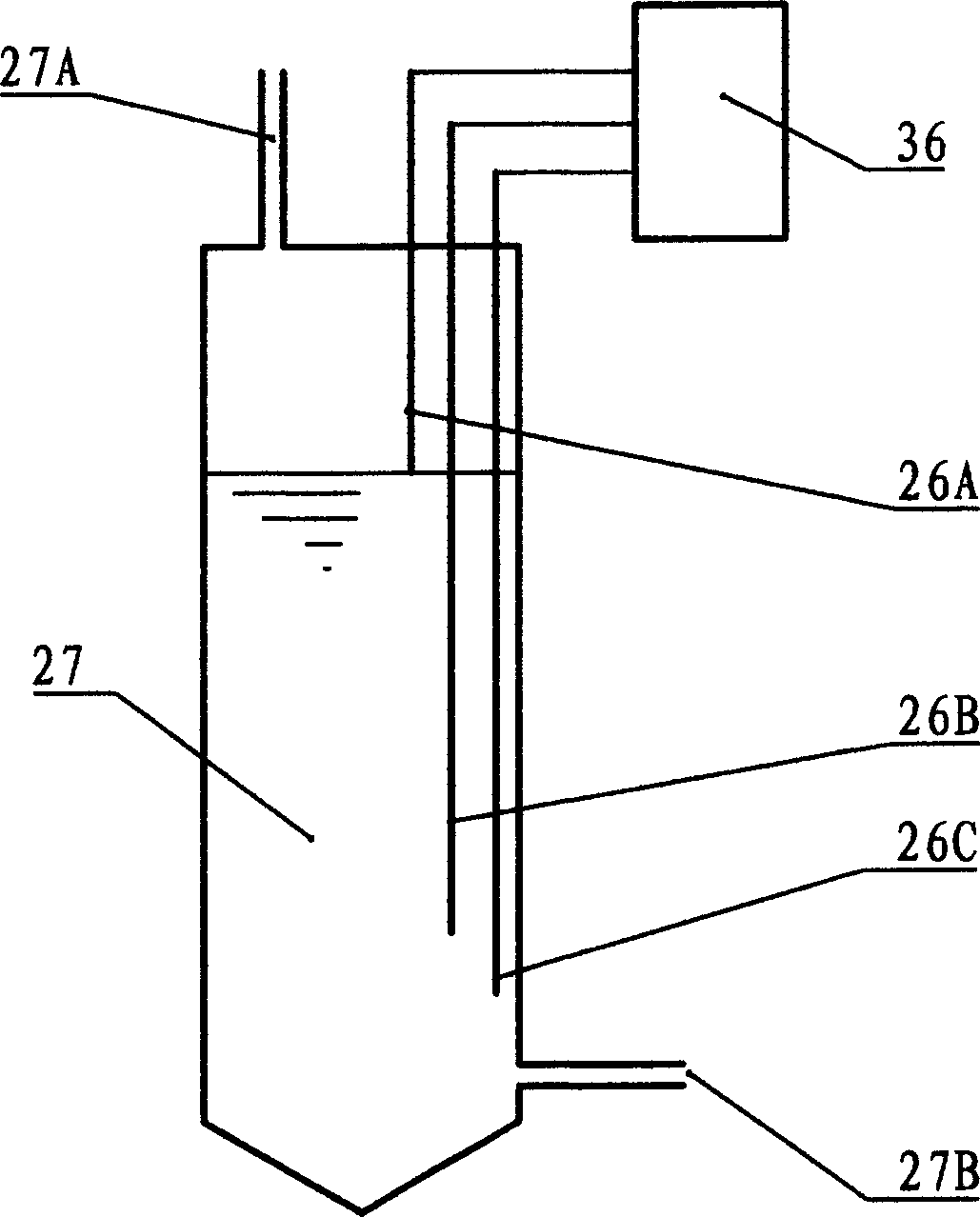

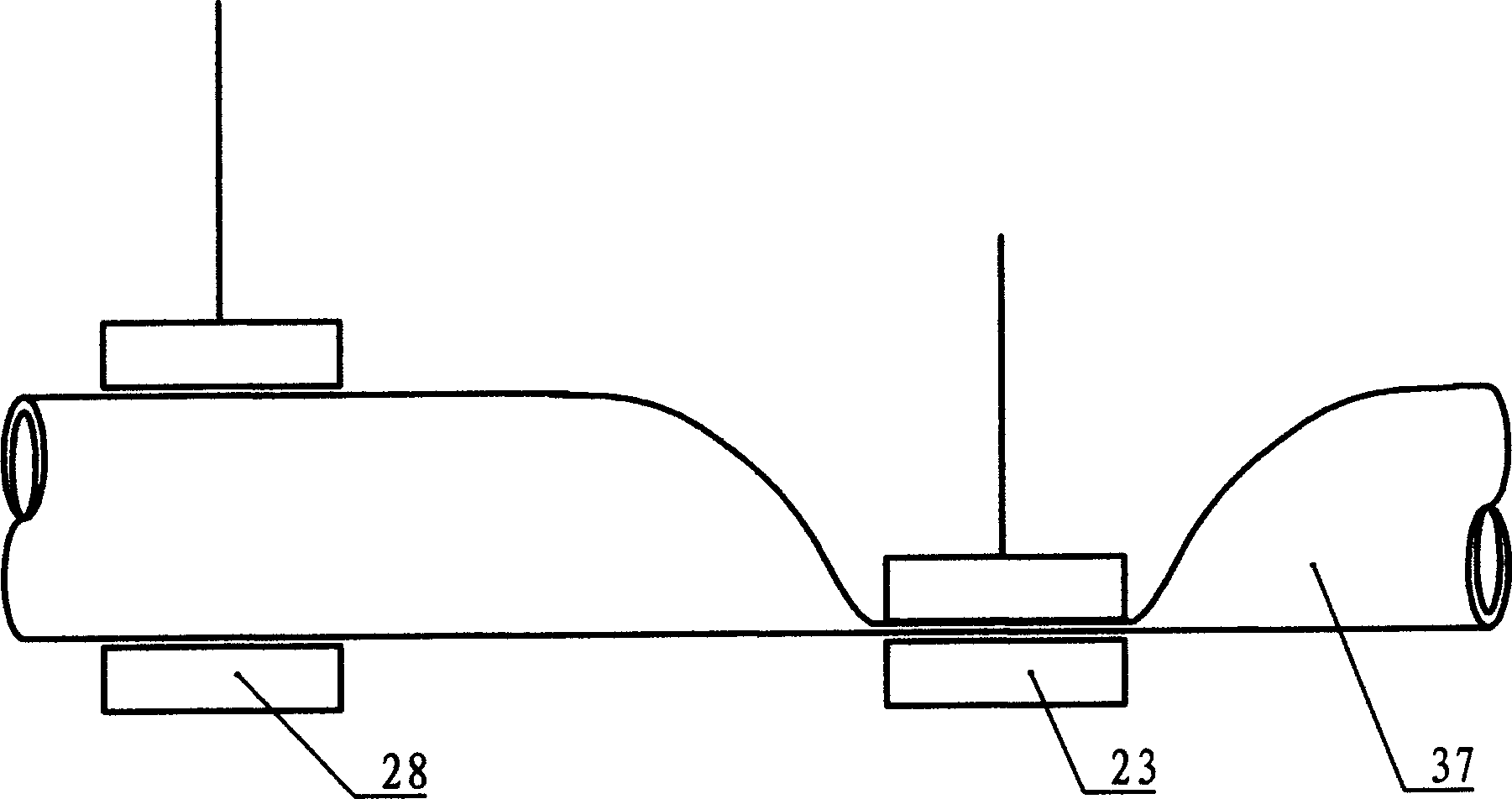

[0021] 1 positive pressure source, 2 two-position three-way solenoid valve, 3 negative pressure reducing valve, 4 two-position three-way solenoid valve, 5 positive pressure reducing valve, 6 two-position three-way solenoid valve, 7 three-position five-way solenoid valve , 8 throttle valve, 9 throttle valve, 10 cylinder, 11 magnetic induction switch, 12 magnetic induction switch, 13 three-position five-way solenoid valve, 14 throttle valve, 15 throttle valve, 16 magnetic induction switch, 17 magnetic induction switch, 18 cylinder , 20 Two-position five-way solenoid valve, 21 Ink source, 22 Cylinder, 23 Shunt type pipeline switch, 26 Sensor, 27 Measuring container, 28 Shunt type pipeline switch, 29 Cylinder, 30 Two-position five-way solenoid valve, 31 Cartridge fixing position , 32 ink cartridges, 33 vacuum switches, 34 two-position two-way solenoid valves, 35 negative pressure sources.

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap