Low-power back illuminating light component

A backlight, low-power technology, applied in the direction of optics, electrical components, nonlinear optics, etc., can solve problems such as impact, shading phenomenon, brightness of backlight components, increase in power consumption of backlight components, etc., to achieve low power consumption rate, The effect of increasing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

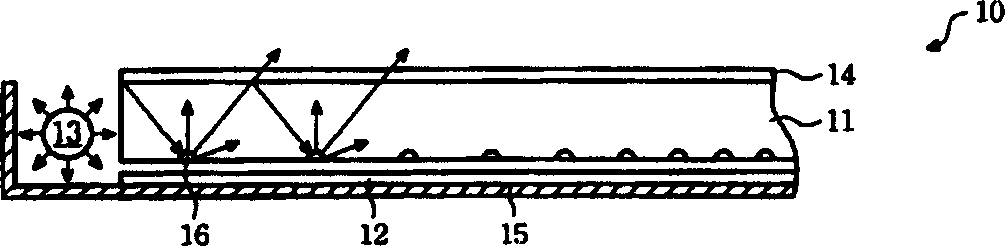

[0030] The invention discloses a low-power backlight assembly. The uniformity of the backlight assembly is increased by means of a fluorescent agent coated on a light guide plate. In addition, the low shading rate of the fluorescent agent can increase the brightness of the backlight assembly and reduce the brightness of the lamp tube. Using current to obtain a low-power backlight assembly, the preferred embodiment of the present invention and its implementation method will be described in detail in the following content.

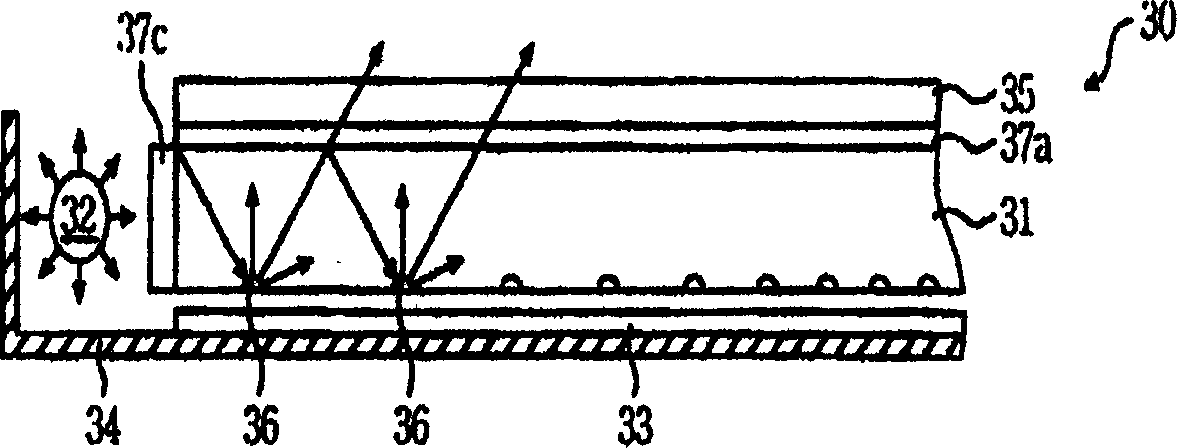

[0031] image 3 It is a cross-sectional view of the low-power backlight assembly 30 of the present invention. The assembly 30 includes a light guide plate 31 , a lamp tube 32 , a reflector 33 , an aluminum back cover 34 and a plurality of optical films 35 . The light guide plate 31 is a plate structure composed of a bottom surface, a top surface and four sides, wherein the sides are perpendicular to the top and bottom surfaces. The material of the light gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com