Method for mfg. semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, construction components on-site preparation, etc., can solve the problems of vertical MOSFET area increase and gate insulating film withstand voltage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

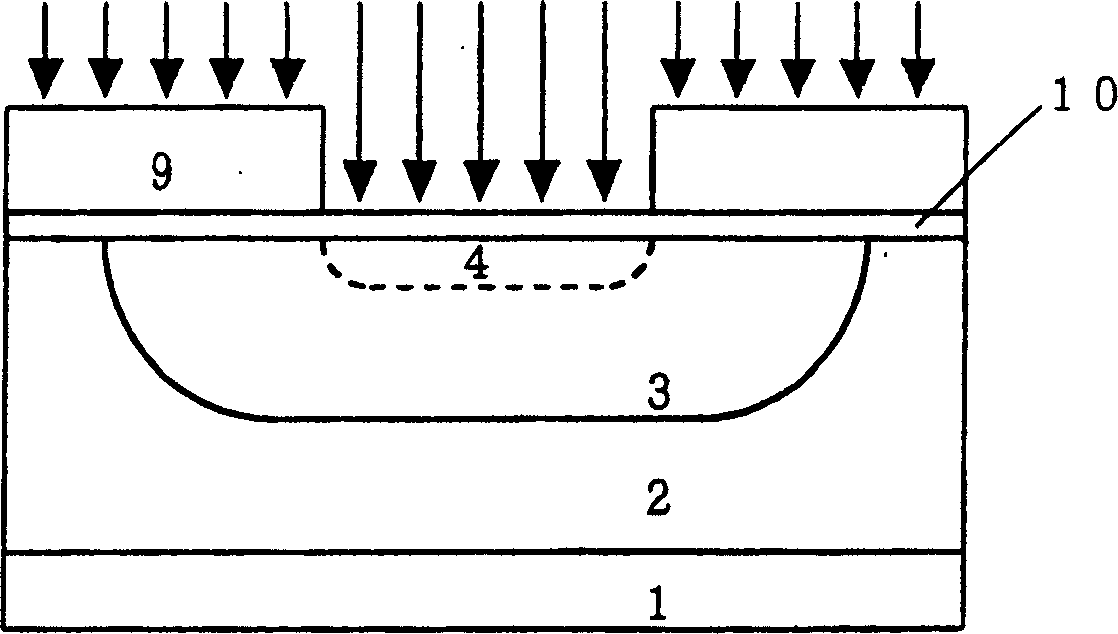

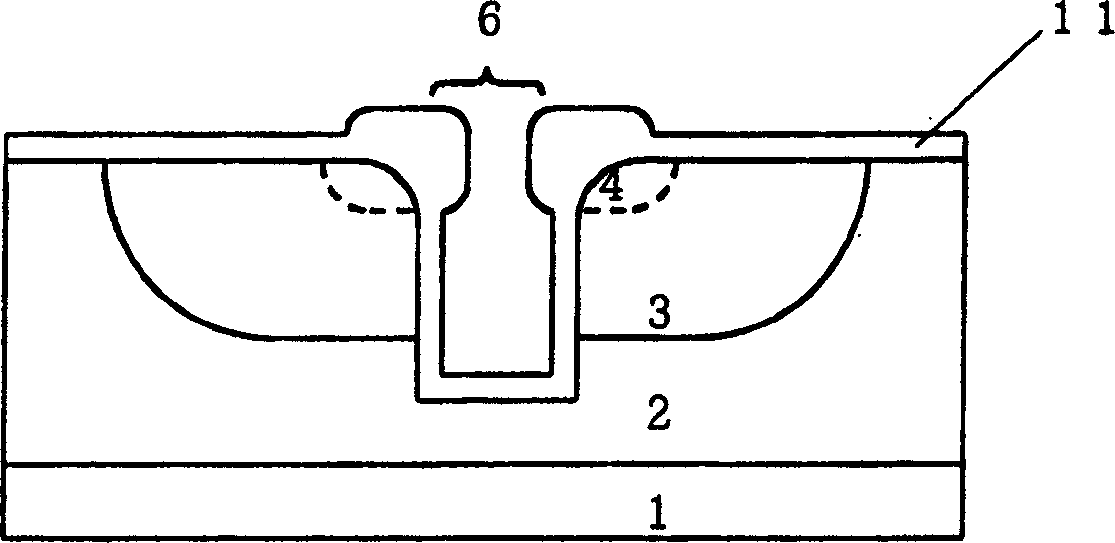

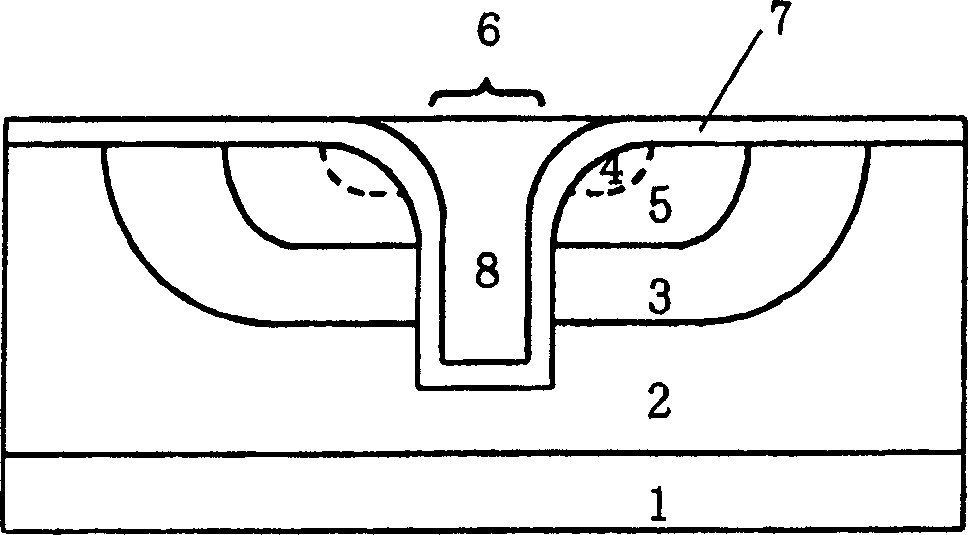

[0030] FIG. 1 is a schematic cross-sectional defect showing a first embodiment of a method of manufacturing a semiconductor device of the present invention. In Fig. 1 (a), on the N+ type semiconductor substrate 1, that is, for example doped with arsenic, the resistivity is 1mΩcm~10mΩcm on the semiconductor substrate of the impurity concentration, form N-semiconductor substrate 2, that is for example doped with phosphorus A semiconductor substrate with a resistivity of 0.1Ωcm to 1Ωcm impurity concentration, on the N-semiconductor substrate 2, for example, ion implantation method with 1 × 10 16 atom / cm 3 ~1×10 18 atom / cm 3 Impurity concentration of boron is implanted to form P- diffusion layer 3 . After the ion implantation, heat treatment for diffusing the P − diffusion layer 3 to a desired depth is performed. After the above-mentioned heat treatment, a photoresist 9 for forming the N-diffusion layer 4 is formed, and the ion implantation method is used to form a 1×10 17 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com