Spring balancer

A spring balancer and coupling technology, applied in the field of spring balancers, can solve the problems of reduced operating efficiency, entanglement of hoses, complicated hoses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

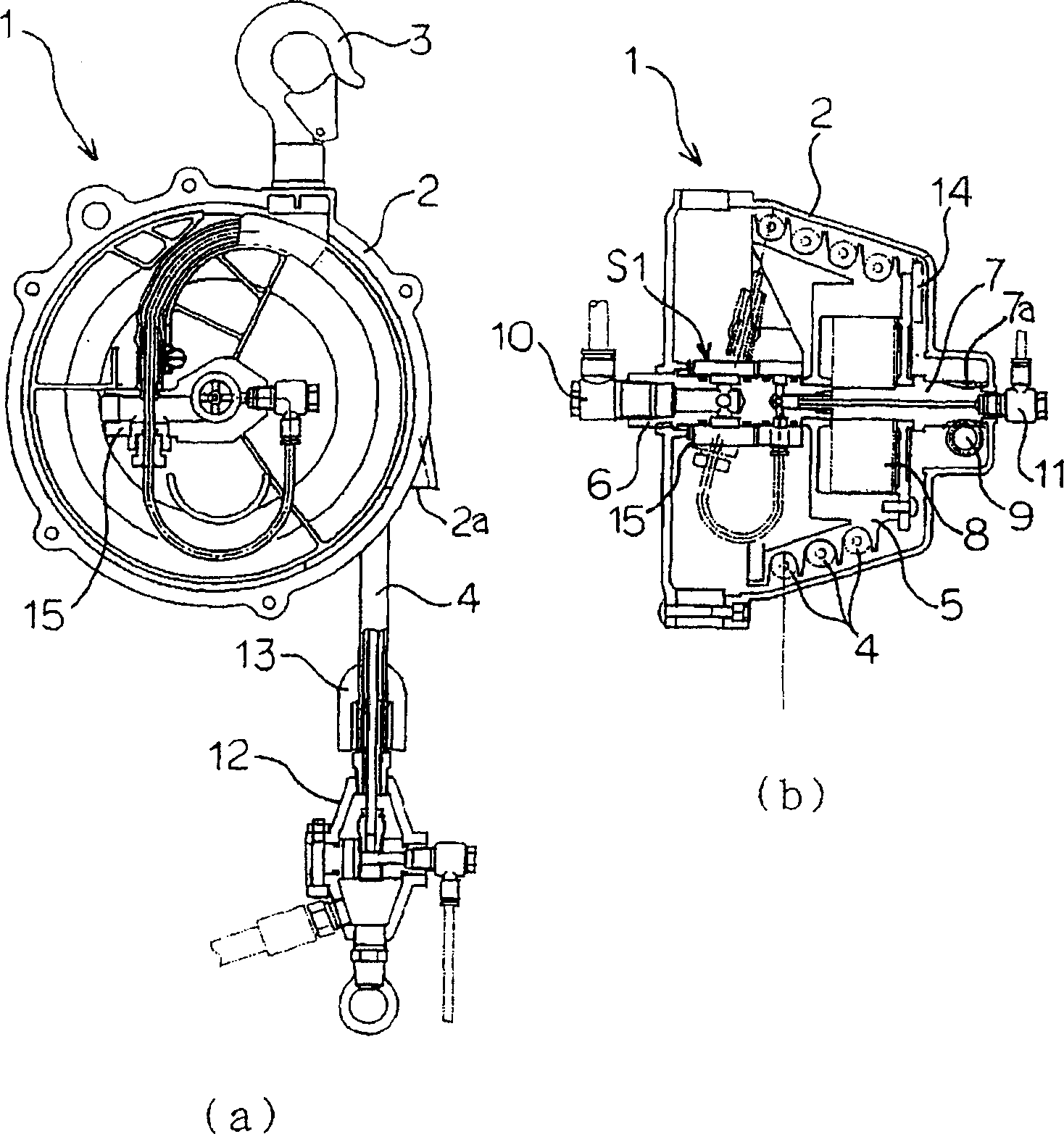

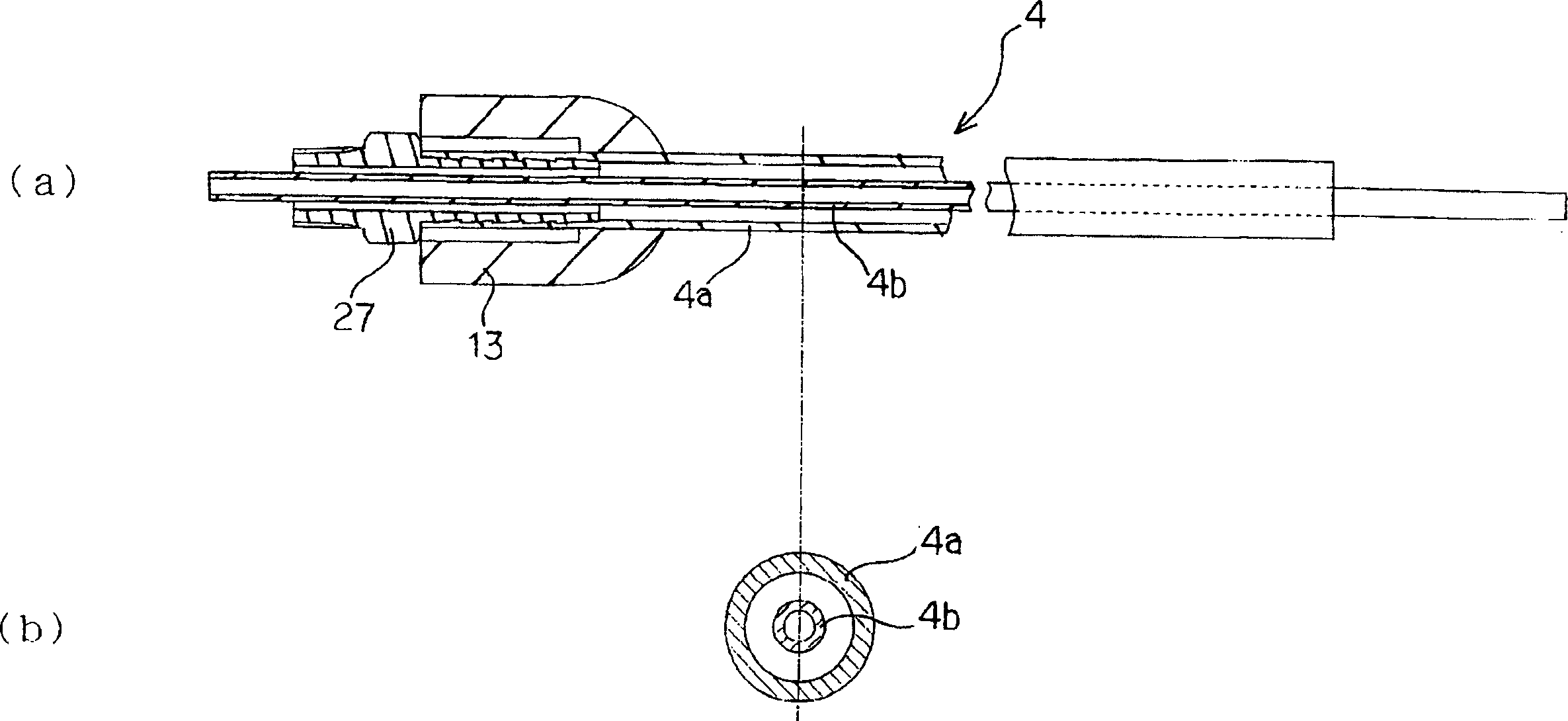

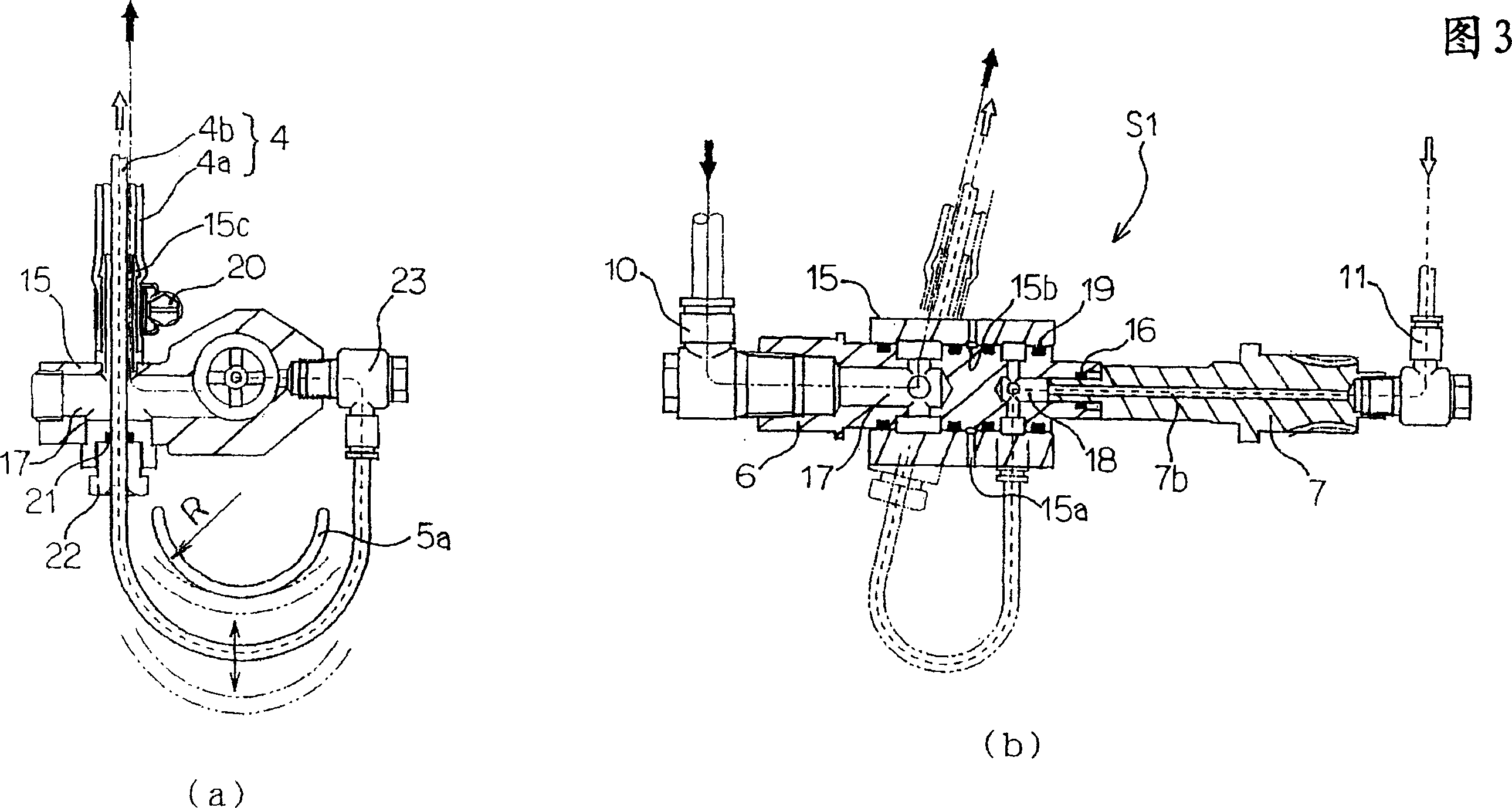

[0030] First refer to Figure 5 The overall structure of the spring balancer of the present invention will be described, and then the configuration of each part will be described in detail in order. Figure 5 It is a figure which shows the spring balancer system (usage example of the spring balancer of this invention) of this invention.

[0031] exist Figure 5 In this case, the spring balancer 1 is suspended by the hook 3 from, for example, a guide rail or the like provided on the ceiling of the work site. A pneumatic tool 34 hangs upside down from the coupler 12 . The pneumatic tool 34 is an air pressure tool that uses compressed air as the rotational power and has a mounting torque detection function.

[0032] In addition, the compressed air primary supply unit 10 and the torque detection signal output unit 11 provided at both ends of the spring balancer 1 are respectively connected to a not-shown compressed air supply source and a work management controller.

[0033] H...

no. 2 example

[0085] Image 6 (a) and (b) are cross-sectional views showing a spring balancer according to a second embodiment of the present invention.

[0086] below, in Image 6 In the spring balancer of the present embodiment shown, the same reference numerals are attached to the parts having the same configuration as those of the above-mentioned first embodiment, and repeated description thereof will be omitted, and the characteristic parts will be described in detail.

[0087] In the spring balancer 41 of this embodiment, the primary side supply part 10 of compressed air and the take-out part 11 of a torque detection signal are arrange|positioned in parallel at one end of this spring balancer 41.

[0088] Here, the structure of the rotary connector 42 in the spring balancer 41 of this embodiment is demonstrated. Figure 7 (a) and (b) are enlarged cross-sectional views showing the rotary connector 42 of the spring balancer 41 of this embodiment.

[0089] The support member S2 is com...

no. 3 example

[0107] The spring balancer of each of the above-mentioned embodiments has a structure in which a double tube type hose is wound on a rotary drum. However, the present embodiment is not limited thereto, and it may be a configuration in which an adhesive hose described later is used instead of a double-tube hose and wound around the rotating drum.

[0108] The spring balancer of the third embodiment of the present invention has the Figure 9 The shown adhesive hose 48 is a spring balancer that is wound around the rotating drum 5 .

[0109] Hereinafter, in the spring balancer of the present embodiment, the same reference numerals are attached to the parts having the same configuration as those of the above-mentioned embodiments, and repeated description thereof will be omitted, and the characteristic parts will be described in detail.

[0110] The spring balancer of this embodiment is the same as the above-mentioned first embodiment, and the primary side supply part 10 of compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com