Installation structure for lining board of fenderboard

A technology for installing structures and fenders, which is applied to the upper structure, upper structure sub-assembly, transportation and packaging, etc., can solve problems such as deformation of fender splash guards, and achieve deformation prevention, precise installation, and firm installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be described below with reference to the embodiments shown in the accompanying drawings.

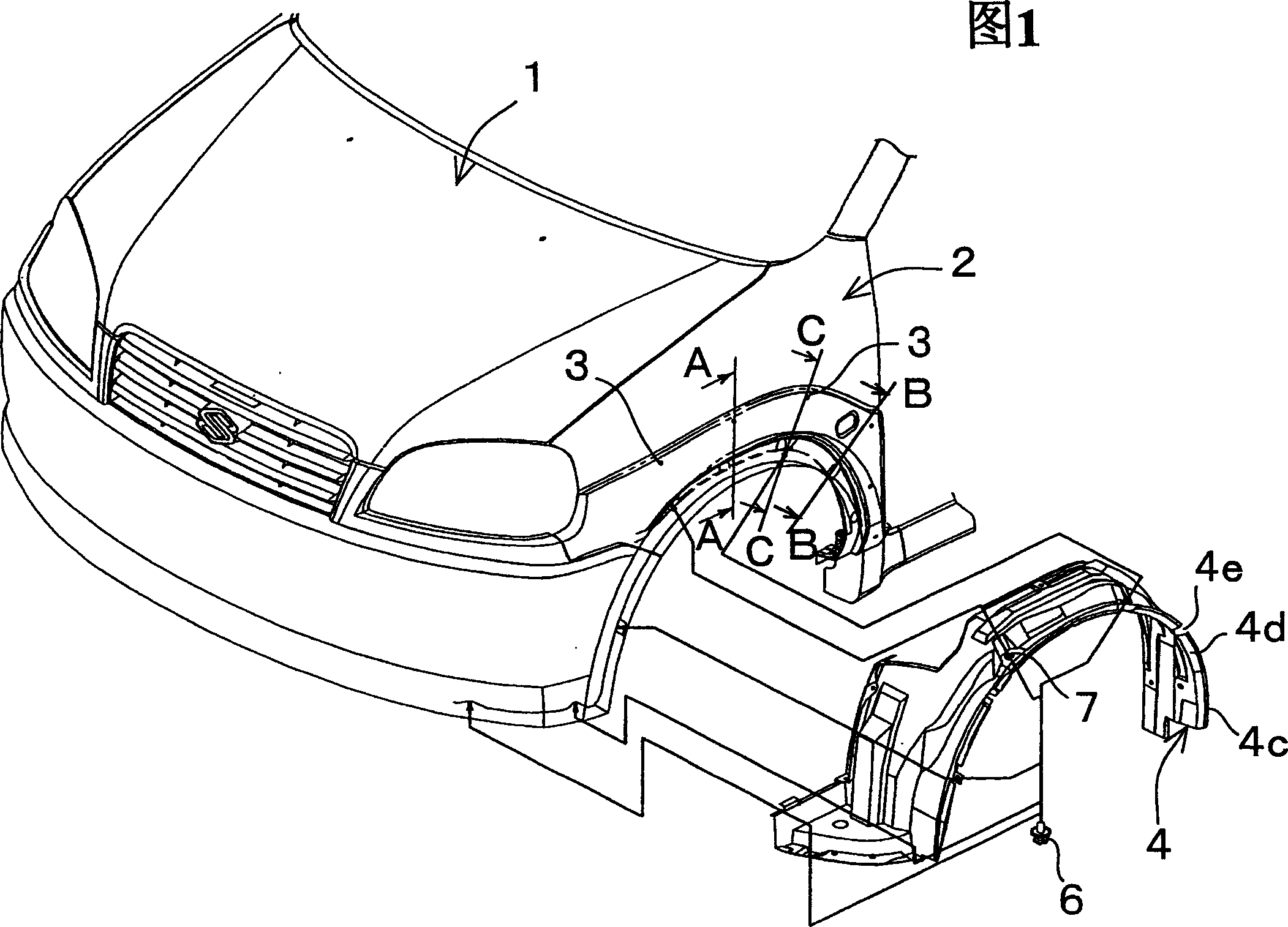

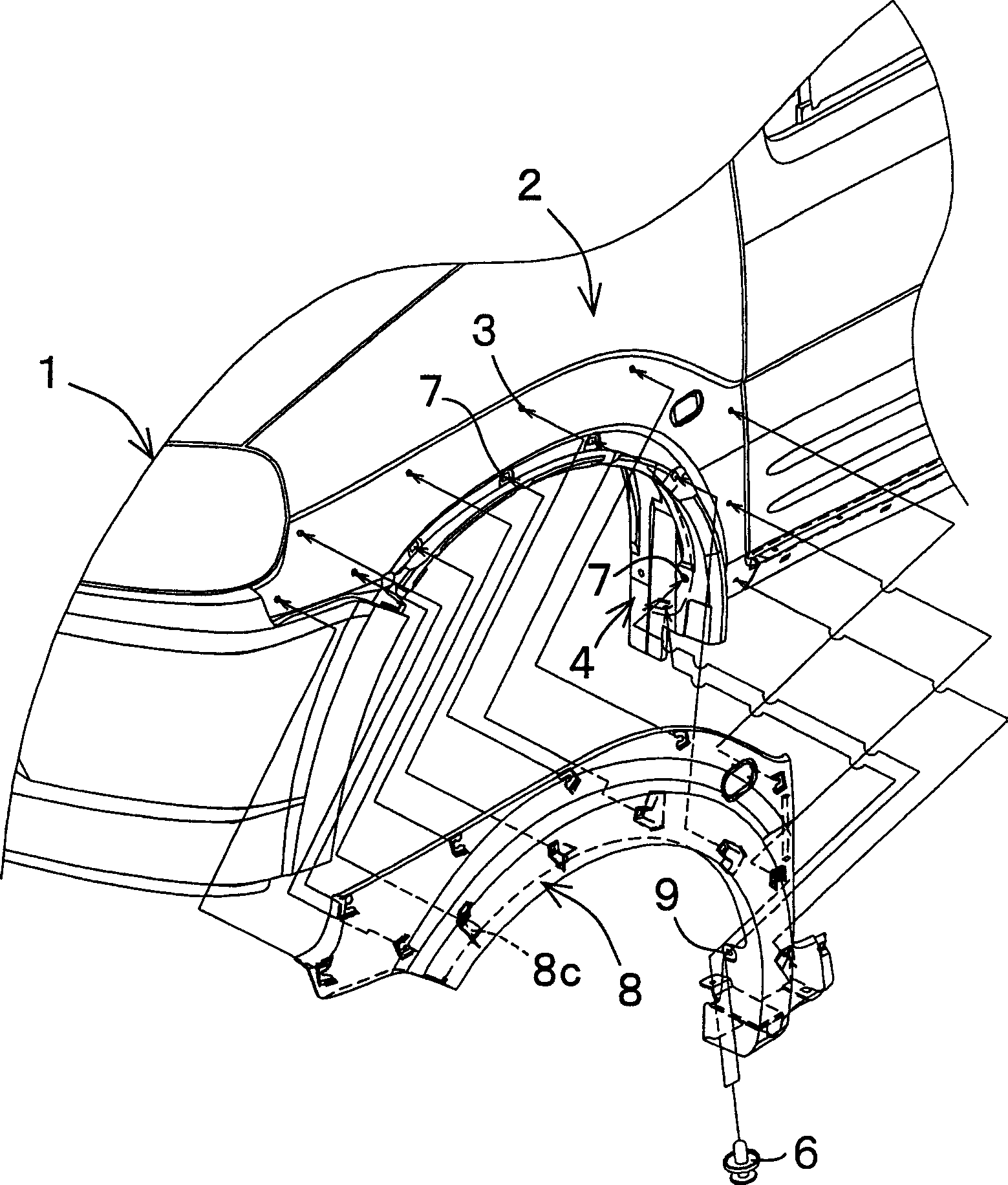

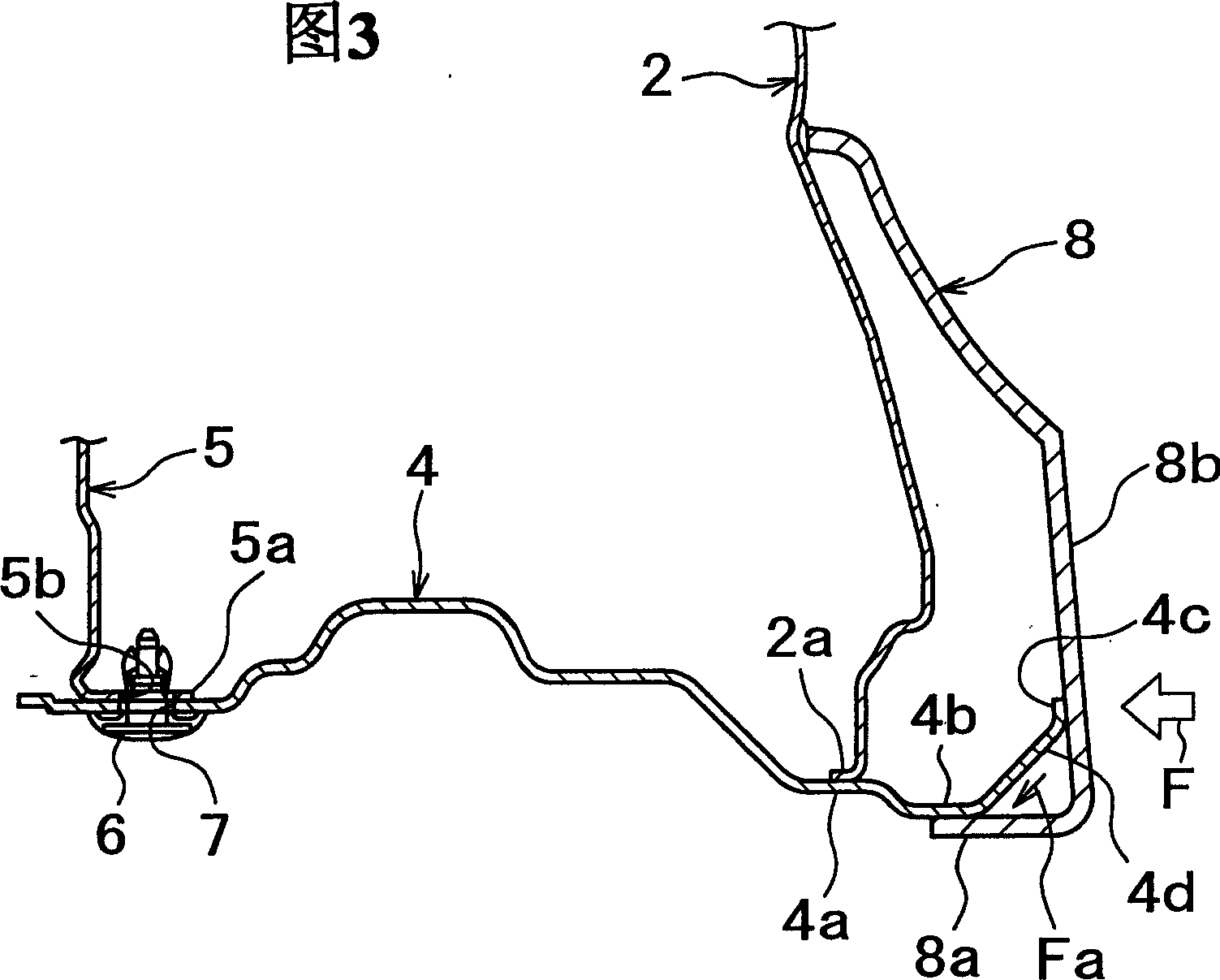

[0028] 1 to 5 show the installation structure of the fender liner according to the present invention. The mounting structure of the present embodiment is used on the left and right sides of the front part of the automobile body, and the front fender 2 is arranged as shown in Fig. 1 and figure 2 shown. At the lower end of this front fender 2, as shown in FIGS. The side surface is formed with a plurality of mounting holes 3 at intervals at predetermined positions. Also, on the inner side of the lower portion of the front fender 2, a front fender liner 4 is provided to surround an upper half (not shown) of a front wheel and prevent mud splashed by the wheel from entering an engine room.

[0029] The front fender liner 4 is an integrally molded product whose entirety is formed in an arc extending longitudinally of the vehicle, is curved upward when viewed from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com