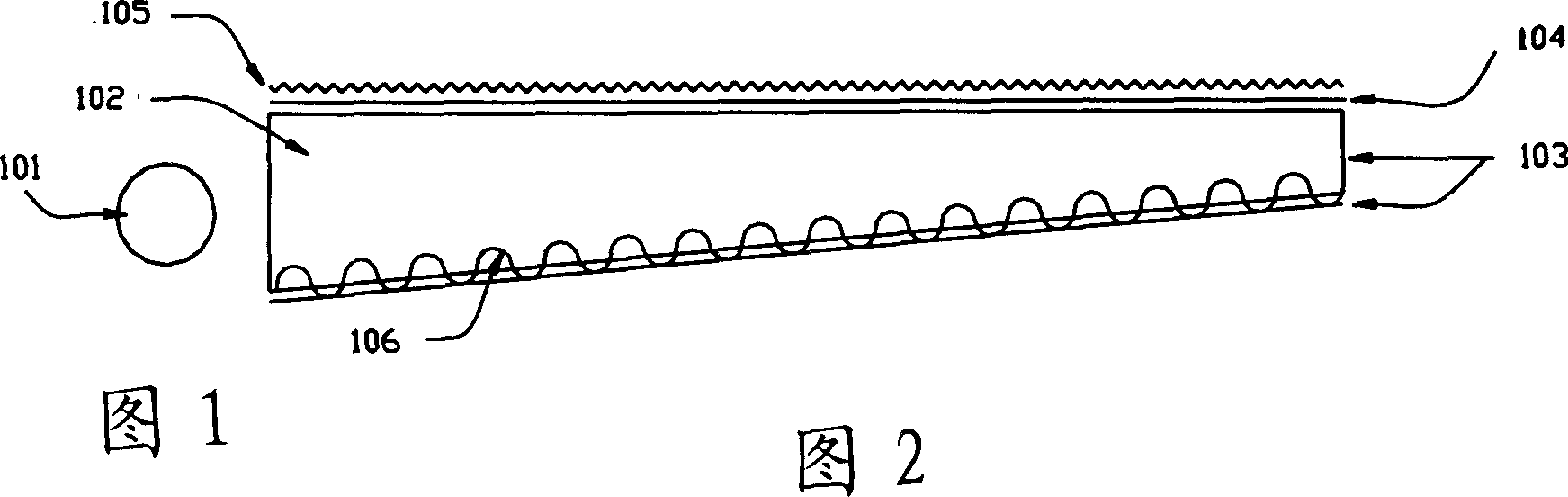

Light conducting plate structure

A light guide plate and lighting technology, applied in optics, nonlinear optics, diffuser elements, etc., can solve problems such as not being able to meet the light uniformity of surface light sources, and achieve the effect of increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

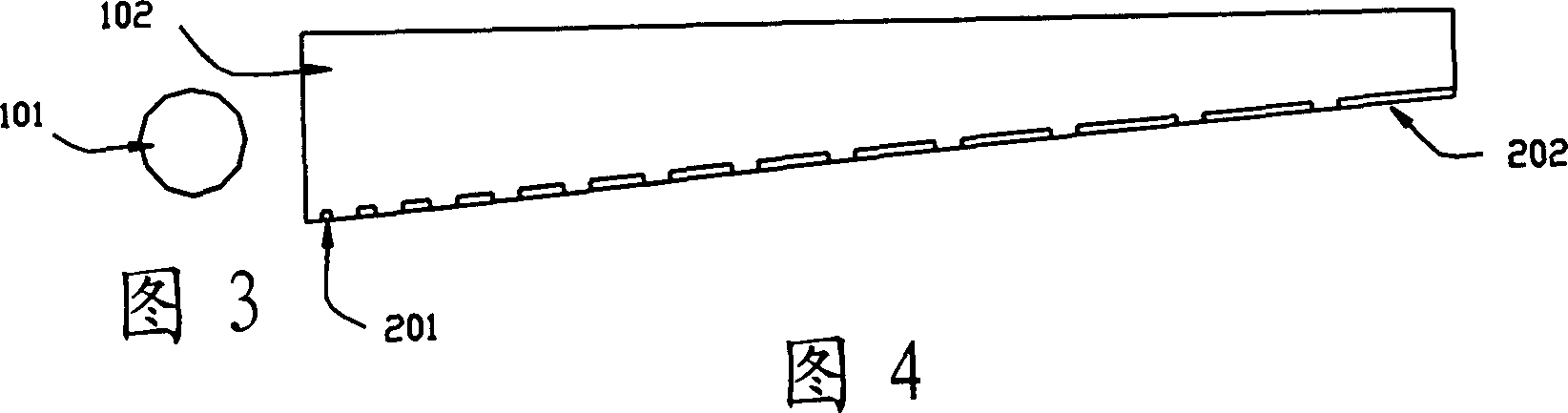

Method used

Image

Examples

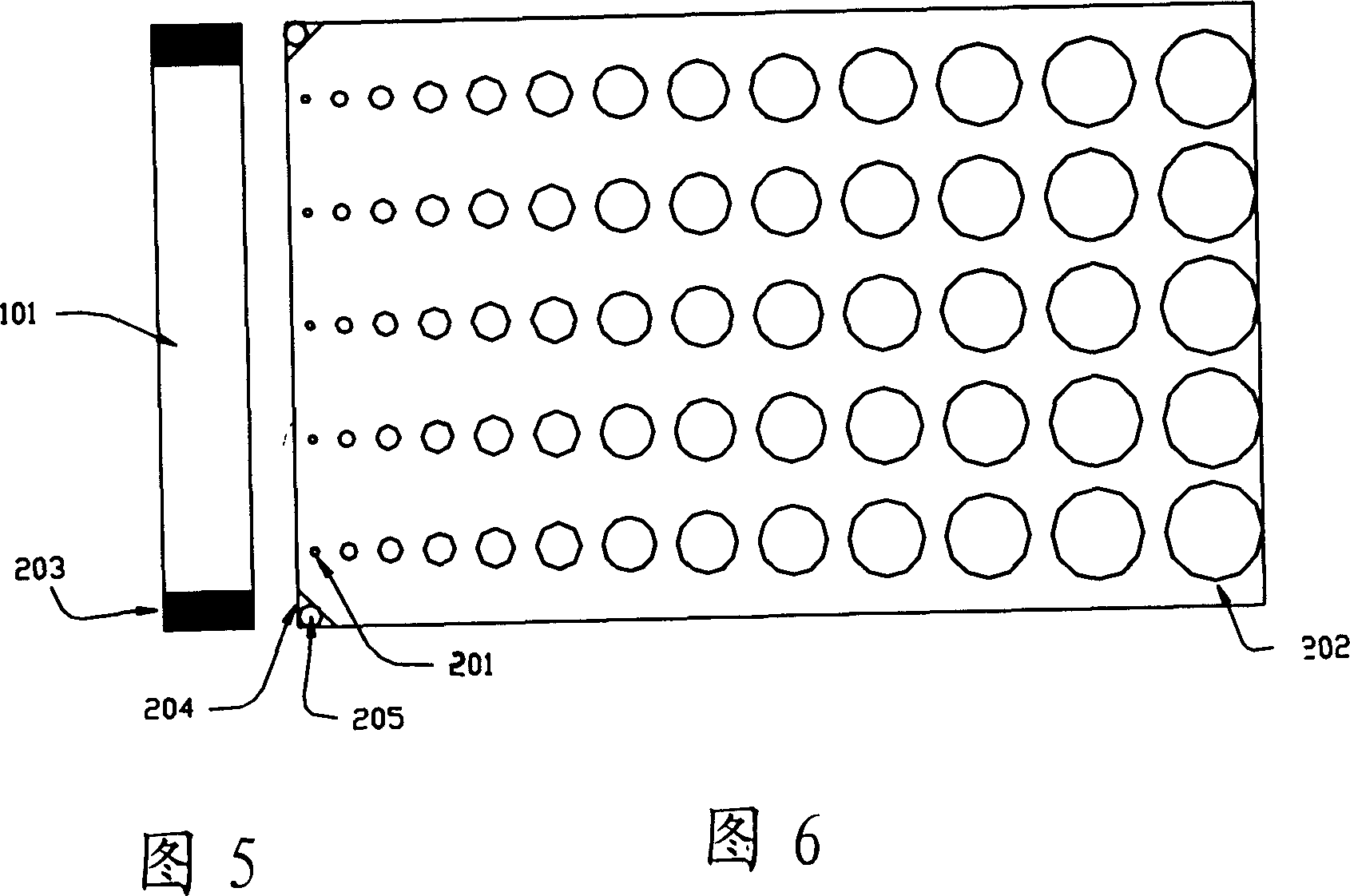

Embodiment 1

[0054] Embodiment 1 is the concentration distribution of the backlight panel in four seasons. An 84mm×60mm light guide plate is made into a hollow pyramid with a bottom of 40μm×30μm and a height of 5μm. First, according to Table 1, the increment Px in the x direction is selected as a fixed value of 125 μm. The increment Py in the Y direction is based on the parabolic formula Y=A(Y-Yo)^2+B(Y-Yo)+C. Substitute Table 2 A, B, C and Yo into Table 1 Formula 2 Get the Coy value first, and then get the increment Py in the Y direction. After calculation, the starting point coordinates of the first five protrusions in the first row are (0, 0) (0, 0.18) (0, 0.35) (0, 0.53) (0, 0.71). The measured uniformity of luminance of this light guide plate was 81%. The density distribution is shown in Figure 13 and Figure 14.

[0055] The second embodiment is another type of concentration distribution of the four-season backlight. A light guide plate of 84mm×60mm is made into a hollow pyramid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com