Pattern brick production technique

A production process and pattern technology, which is applied in the field of pattern tile production technology, can solve the problems of kiln workers being difficult to maintain their livelihood, and the tile production process is lost, and achieves good decorative effects, clear and quiet colors, and clear textures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

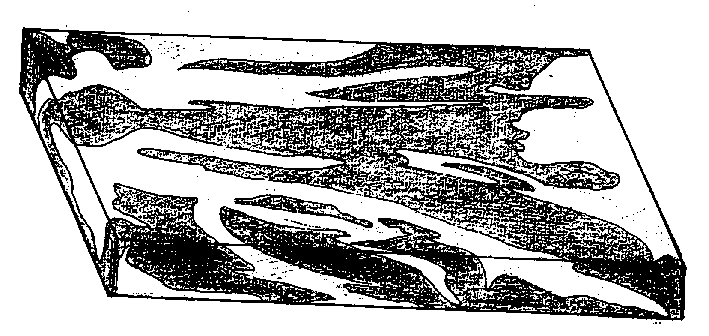

[0021] Embodiment 1: fine pattern brick production process

[0022] This embodiment includes material selection, forging mud, billet kneading, mold entry, drying, kiln loading and calcination, water injection and boring of bricks, and kiln exit.

[0023] A. Material selection: choose 3 kinds of clay raw materials, white calcareous hemp sandy mud field soil, yellow hemp stone red loam soil and black sandy mud field subsoil, which are dried, crushed and sieved, put into a container, add water and stir into mud, and then filter and precipitate into clear mud , take it out after removing the water, place it in a cool and ventilated place, and dry in the shade until the water content is 10-20%.

[0024] B. Forging mud: Forge and knead the shade-dried clear mud by manual or mechanical hammering to make it soft, have bones and tendons, resemble gluten, and be very tough.

[0025] C. Kneading: take 30% of the white calcareous hemp sandy mud field soil forging mud, 20% of the yellow h...

Embodiment 2

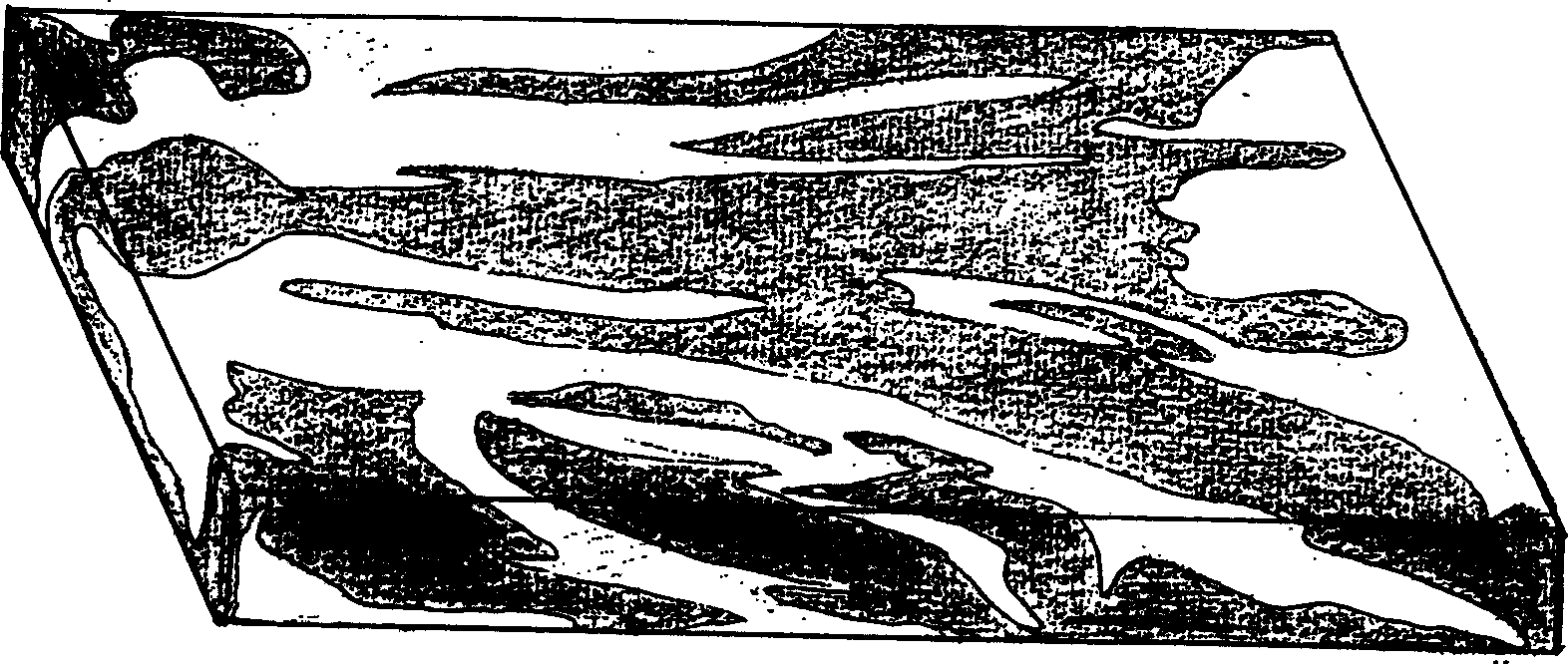

[0031] Embodiment 2: rough pattern brick production process

[0032] In this embodiment, except for the kneading process, all the other processes are the same as in Embodiment 1.

[0033] Kneading: Take 40% of white calcareous hemp sandy field soil forging mud, 30% of yellow hemp stone red loam soil, and 40% of black sandy mud field subsoil forging mud. rough billet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com