Clay brick and preparation method thereof

A technology of clay bricks and clay, which is applied in the production of clay products, other household utensils, ceramic materials, etc. It can solve the problems of cultivated land, farmland, vegetation damage, low calorific value that cannot be directly used, and clay brick sintering constraints, etc., to achieve sintering time The effect of shortening, low production cost and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]The clay brick raw material is composed of tailings and fly ash; the mass percentage of the tailings is 70%, and the mass percentage of the fly ash is 30%; Obtained directly, the mass percentage of each component in the tailings is: SiO 2 62%, Al 2 o 3 17%, Fe 2 o 3 5%, CaO 2%, MgO 2%, and the rest are other elements; the plasticity index of the tailings is 12, and the calorific value is 1.8 MJ / kg. Tailings particle size <0.045mm. Fly ash particle size <2mm.

[0064] The clay brick preparation method is as follows:

[0065] Step 1: Transport the tailings to the slime dryer to dry until the moisture content is 15-18%;

[0066] Step 2: Sieve the fly ash through a drum sieve to obtain a fly ash particle size <2mm;

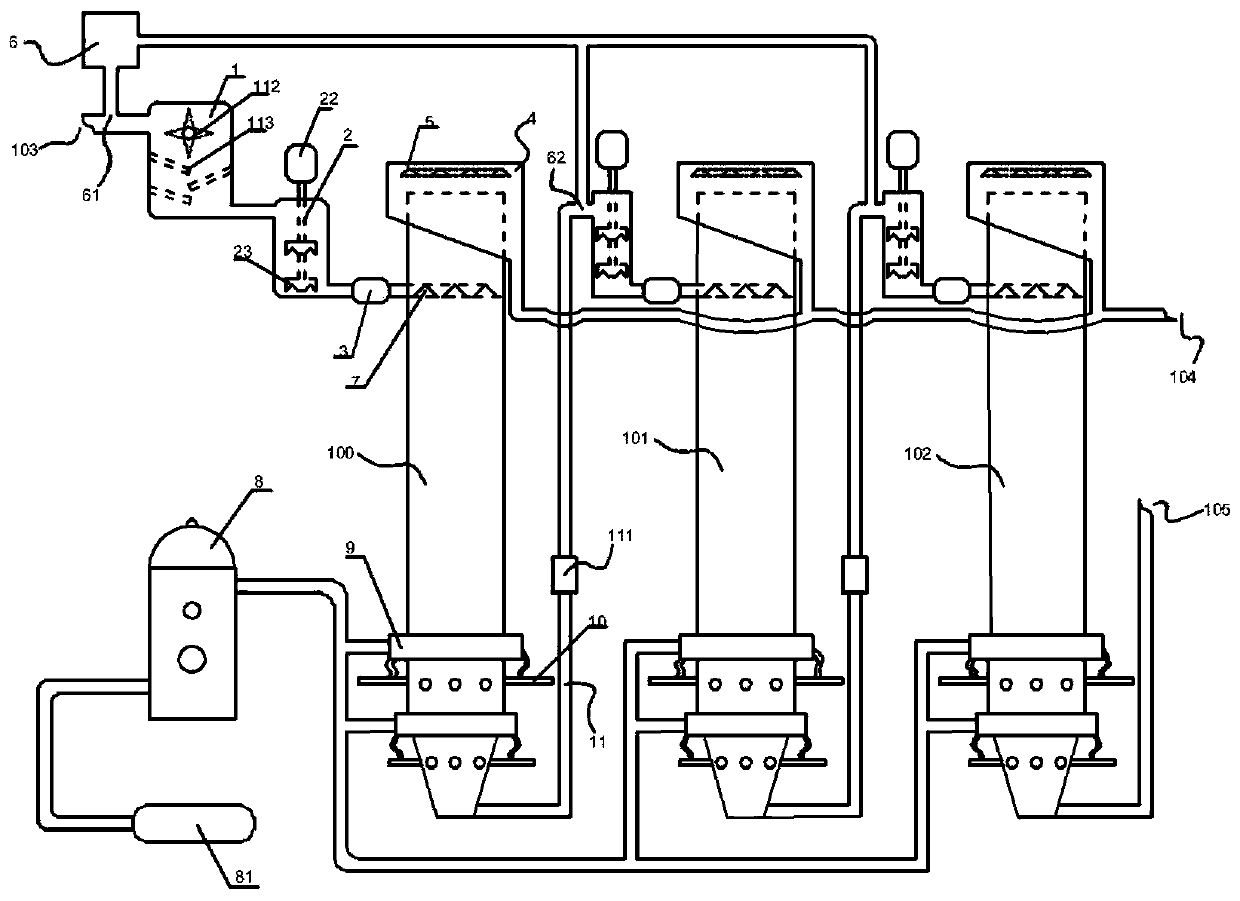

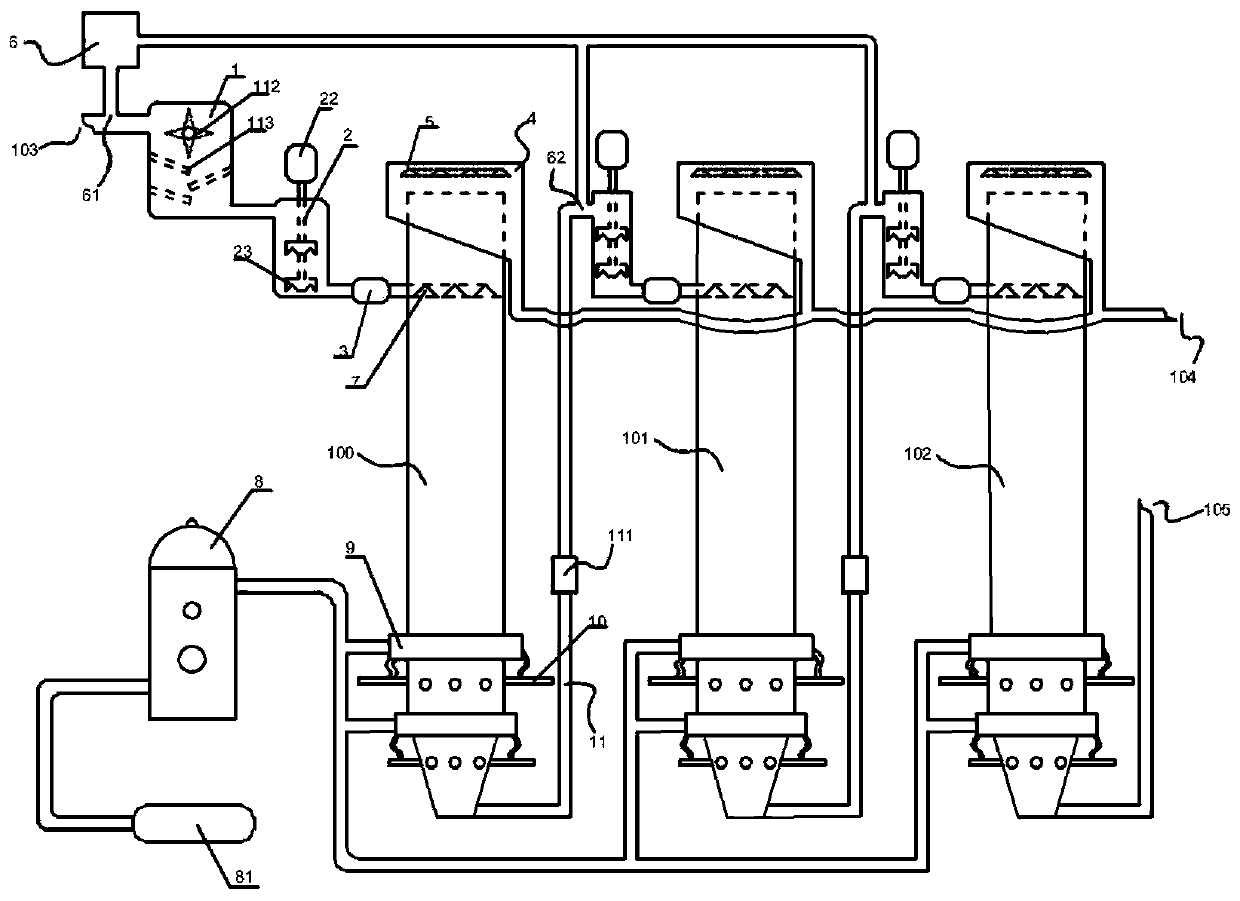

[0067] Step 3: Mix the fly ash obtained in step 2 with the tailings obtained in step 1 in proportion, and then transport them to two continuous first and second mixing systems of SJJ280×36 for mixing and rolling; the mixing of the first mixing system Th...

Embodiment 2

[0072] The clay brick raw material is composed of tailings and fly ash; the mass percentage of the tailings is 80%, and the mass percentage of the fly ash is 20%; Obtained directly, the mass percentage of each component in the tailings is: SiO 2 66%, Al 2 o 3 16%, Fe 2 o 3 is 5%, CaO is 1%, MgO is 1%, and the rest are other elements; the plasticity index of the tailings is 16, the calorific value is 1.9 MJ / kg, and the loss on ignition is 5%. Tailings particle size <0.045mm. Fly ash particle size <2mm.

[0073] The clay brick preparation method is as follows:

[0074] Step 1: Transport the tailings to the slime dryer to dry until the moisture content is 15-18%;

[0075] Step 2: Sieve the fly ash through a drum sieve to obtain a powder with a particle size of less than 2 mm.

[0076] Step 3: Mix the fly ash obtained in step 2 with the tailings obtained in step 1 in proportion, and then transport them to two continuous first and second mixing systems of SJJ280×36 for mixi...

Embodiment 3

[0081] The clay brick raw material is composed of tailings and fly ash; the mass percentage of the tailings is 90%, and the mass percentage of the fly ash is 10%; the tailings are separated from the coal slime through a separation column Obtained directly, the mass percentage of each component in the tailings is: SiO 2 76%, Al 2 o 3 15%, Fe 2 o 3 2%, CaO 0.5%, MgO 0.5%, and the rest are other elements; the plasticity index of the tailings is 18, and the calorific value is 2.1MJ / kg. Tailings particle size <0.045mm. Fly ash particle size <2mm.

[0082] The clay brick preparation method is as follows:

[0083] Step 1: Transport the tailings to the slime dryer to dry until the moisture content is 15-18%;

[0084] Step 2: Sieve the fly ash through a drum sieve to obtain a powder with a particle size of <2 mm.

[0085] Step 3: Mix the fly ash obtained in step 2 with the tailings obtained in step 1 in proportion, and then transport them to two continuous first and second mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com