Channel joint leakage prevention construction method

A construction method and channel technology, applied in water conservancy projects, marine engineering, irrigation pipelines, etc., can solve the problems of channel damage to the channel body, the concrete is not compacted, and the frost heave resistance is poor, and the effect of solving joint cracks is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor. It should be noted that this embodiment is only a preferred example, and the present invention is not limited to these embodiments.

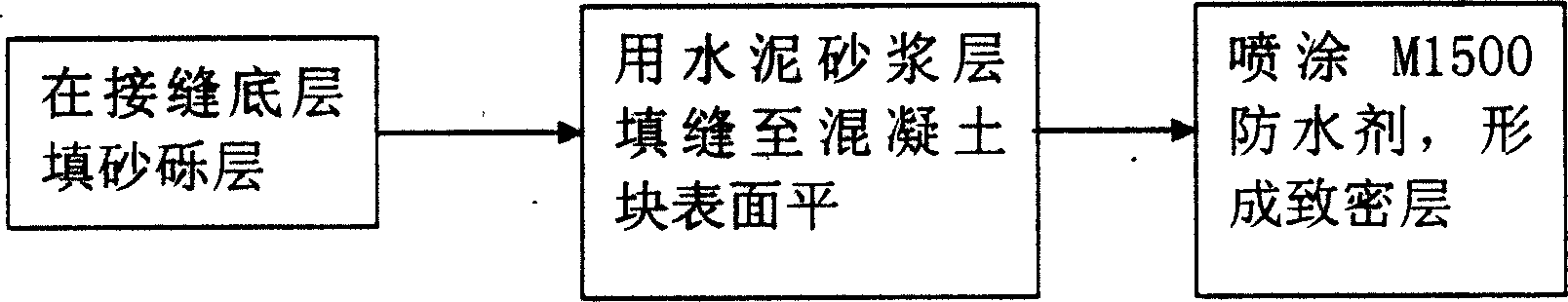

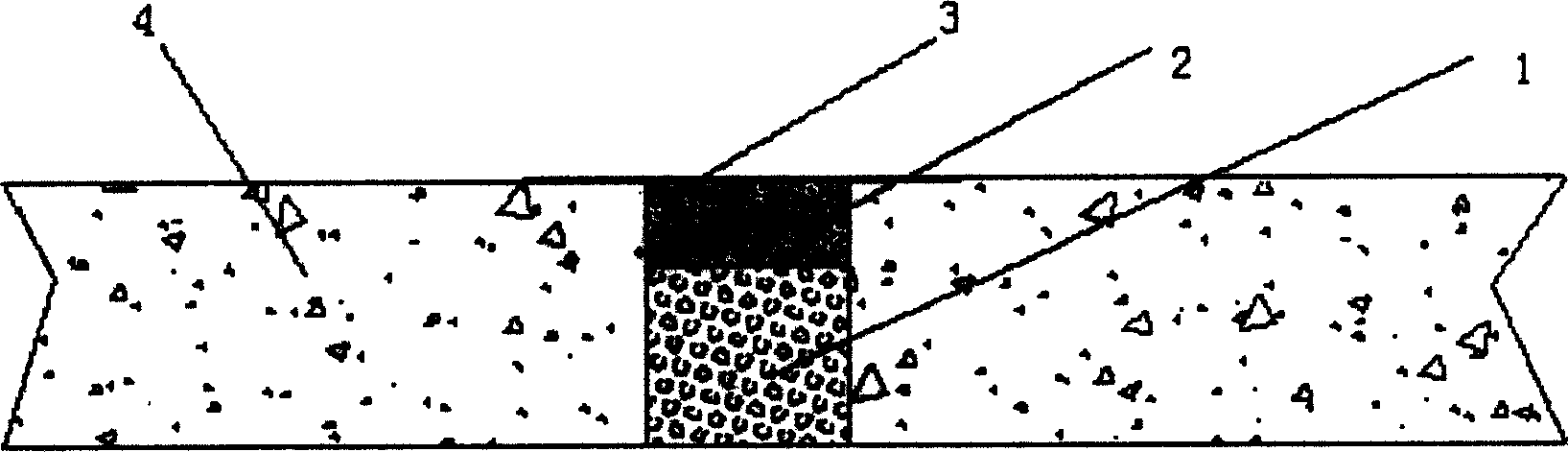

[0016] Referring to the accompanying drawings, according to the technical scheme of the present invention, for laying prefabricated or cast-in-place concrete block 4 for the channel, the width of the seam is 3.0cm~8.0cm, and the depth of the seam is more than 5.0cm; 1.0cm of mixed gravel forms the gravel layer 1, and the gravel layer is 3.0cm away from the surface of the concrete block; then, the ordinary cement mortar layer 2 is used to fill the joint sand layer until the surface of the two concrete blocks is flat; add the cement mortar layer Finally, spray M1500 waterproofing agent 0.22kg / m on the joint surface of the concrete block and on both sides within the range of 3.0cm to 5.0cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com