Process and installation for the distribution of air enriched in oxygen to passengers of an aircraft

An oxygen-enriched air, aircraft passenger technology, applied in aircraft parts, separation methods, transportation and packaging, etc., can solve problems such as increasing aircraft weight, and achieve the effect of reducing fuel capacity, ensuring weight, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

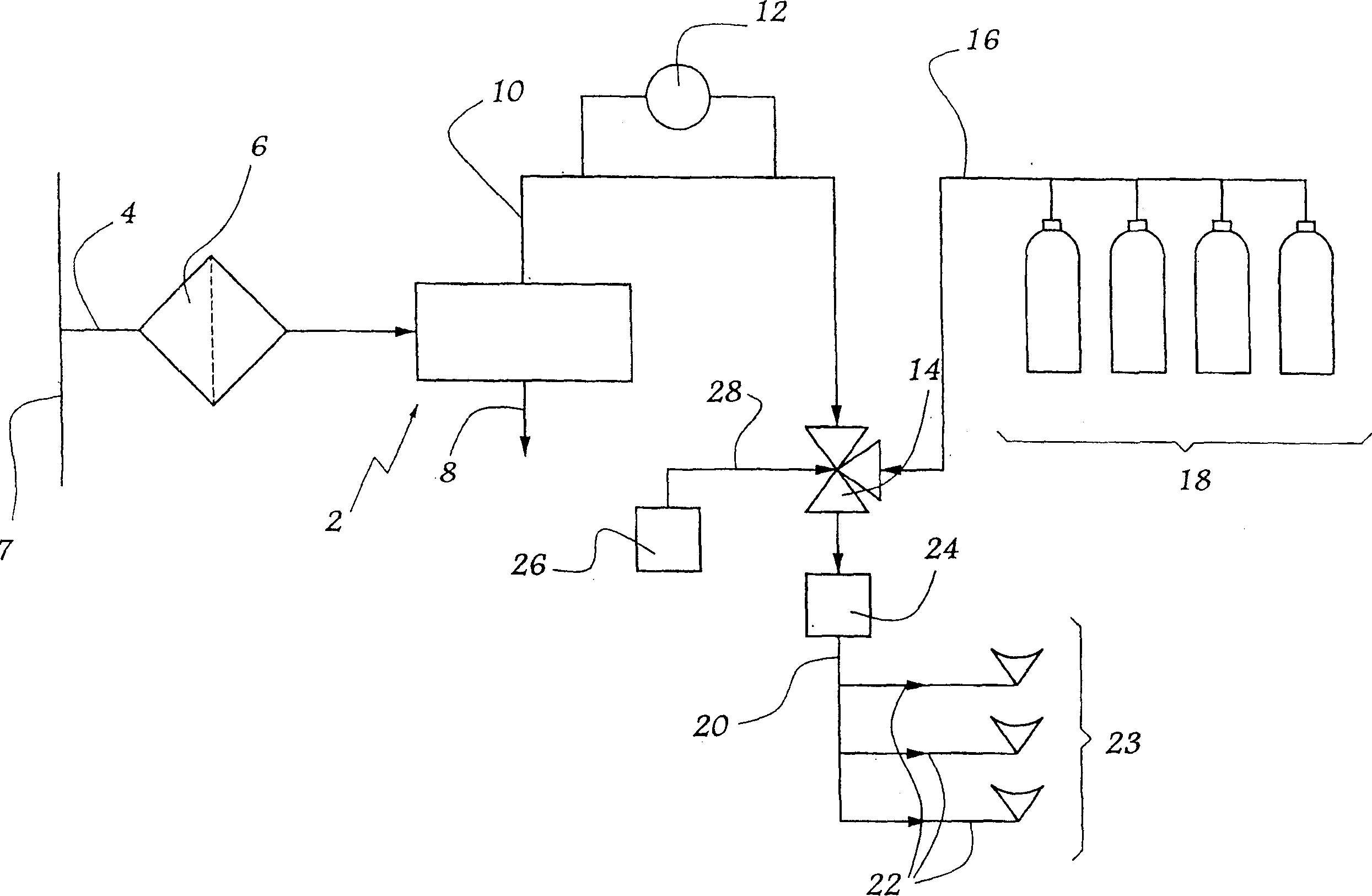

[0017] The distribution unit shown in the figure comprises an oxygen separator or concentrator of a known type generally indicated by reference numeral 2 . The concentrator which separates the oxygen and nitrogen contained in the air generally uses molecular sieves known per se, especially zeolites. As output, the concentrator delivers oxygen-enriched air with an oxygen concentration advantageously between 60% and 95%, typically between 80% and 93%, at low pressure, usually between 1.5 and 2.5 bar relative pressure between.

[0018] The concentrator 2 is connected via a line 4 provided with a filter 6 to a compressed air source 7 inside the aircraft. This gas source is formed, for example, by the air conditioning cycle of an aircraft, or by the outflow (gas) of the compression stage of a jet engine.

[0019] The illustrated concentrator 2 comprises an outlet line 8 from which nitrogen-enriched air flows and a line 10 in which oxygen-enriched air flows. Said line 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com