Cotton cloth made rag cleaning machine

A sweeping machine and rag technology, applied in the direction of cleaning carpets, floors, cleaning machines, etc., can solve the problems of rising manufacturing costs and a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

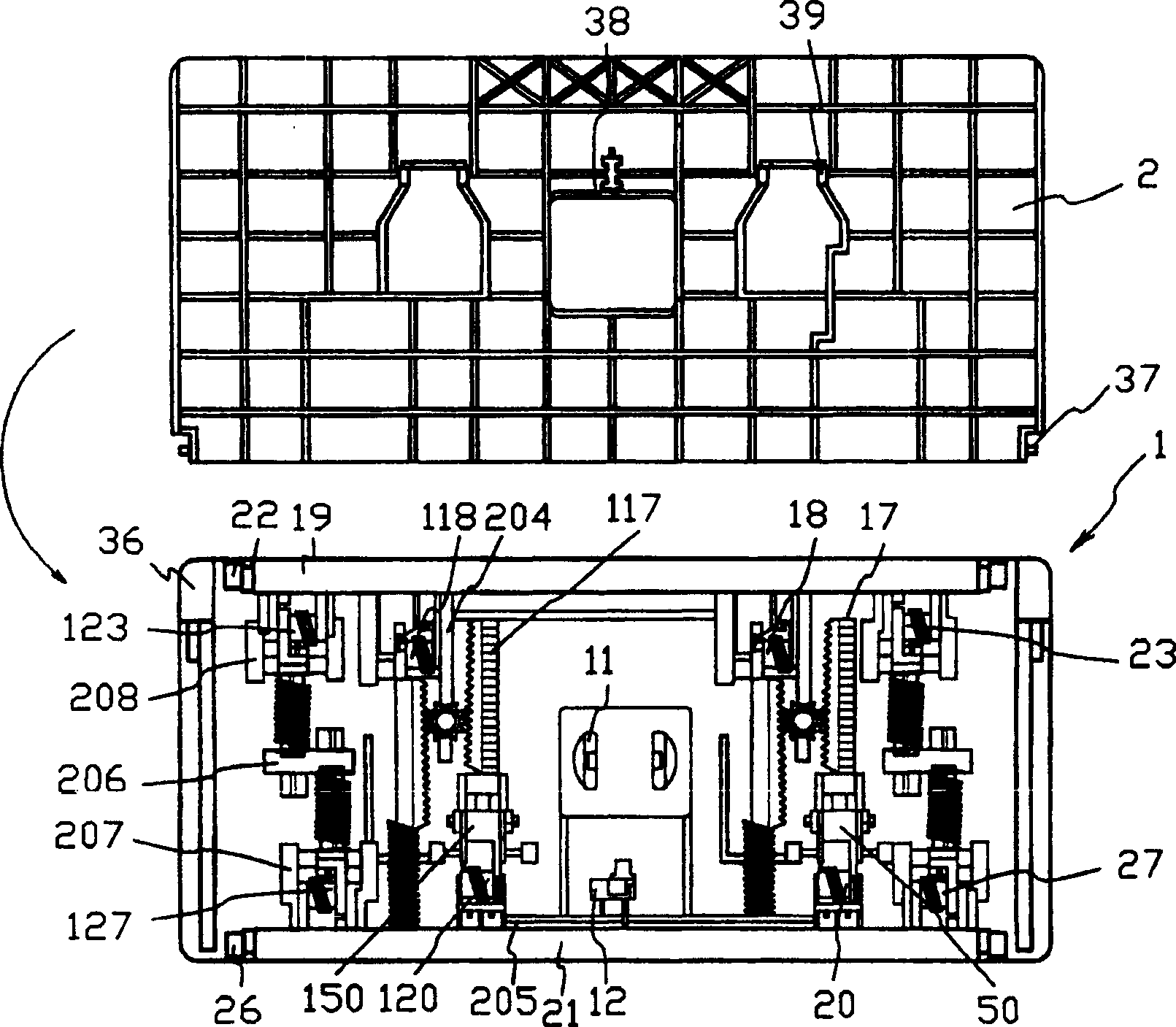

[0026] Hereinafter, the contents of the present invention will be described in detail with reference to the drawings.

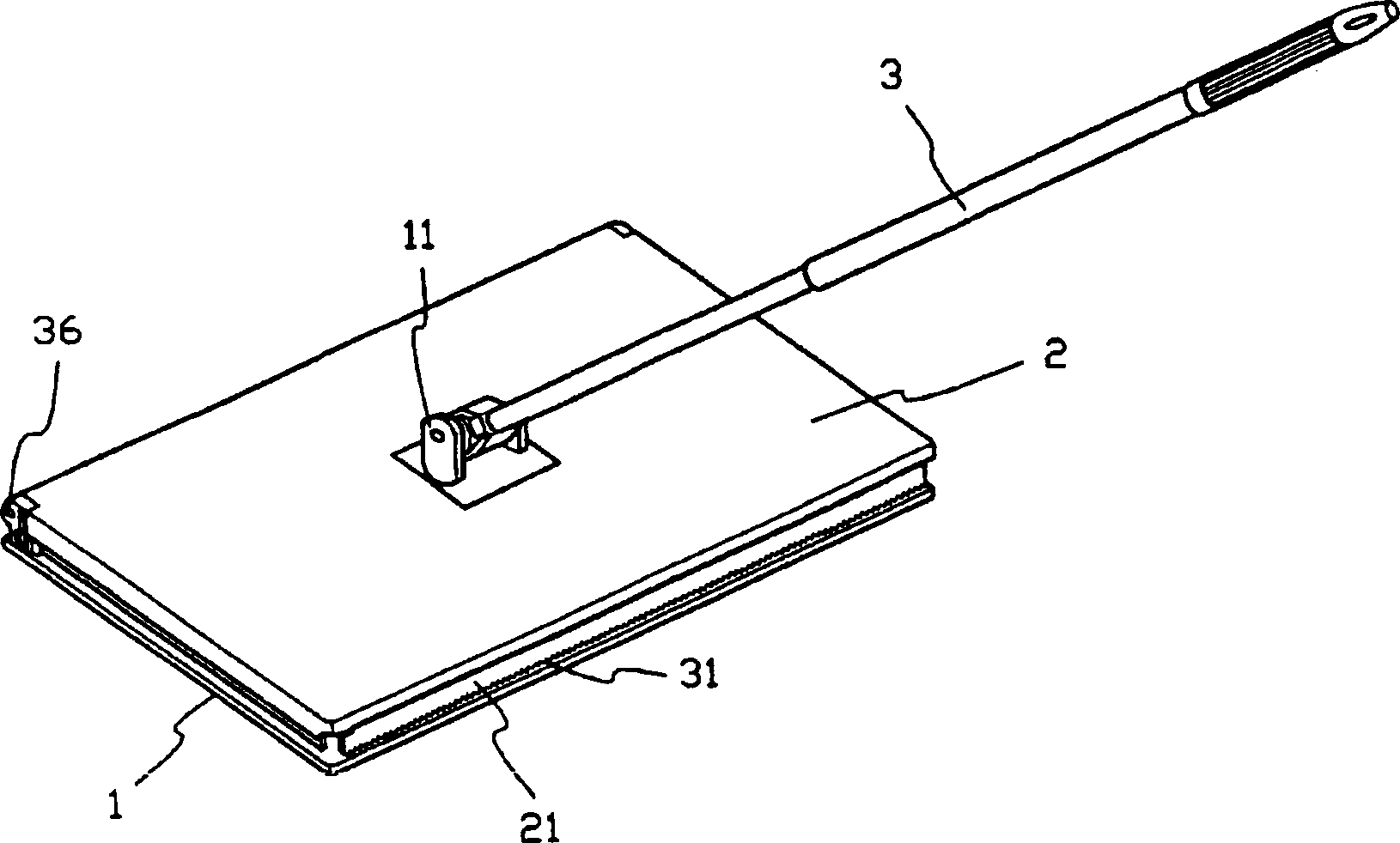

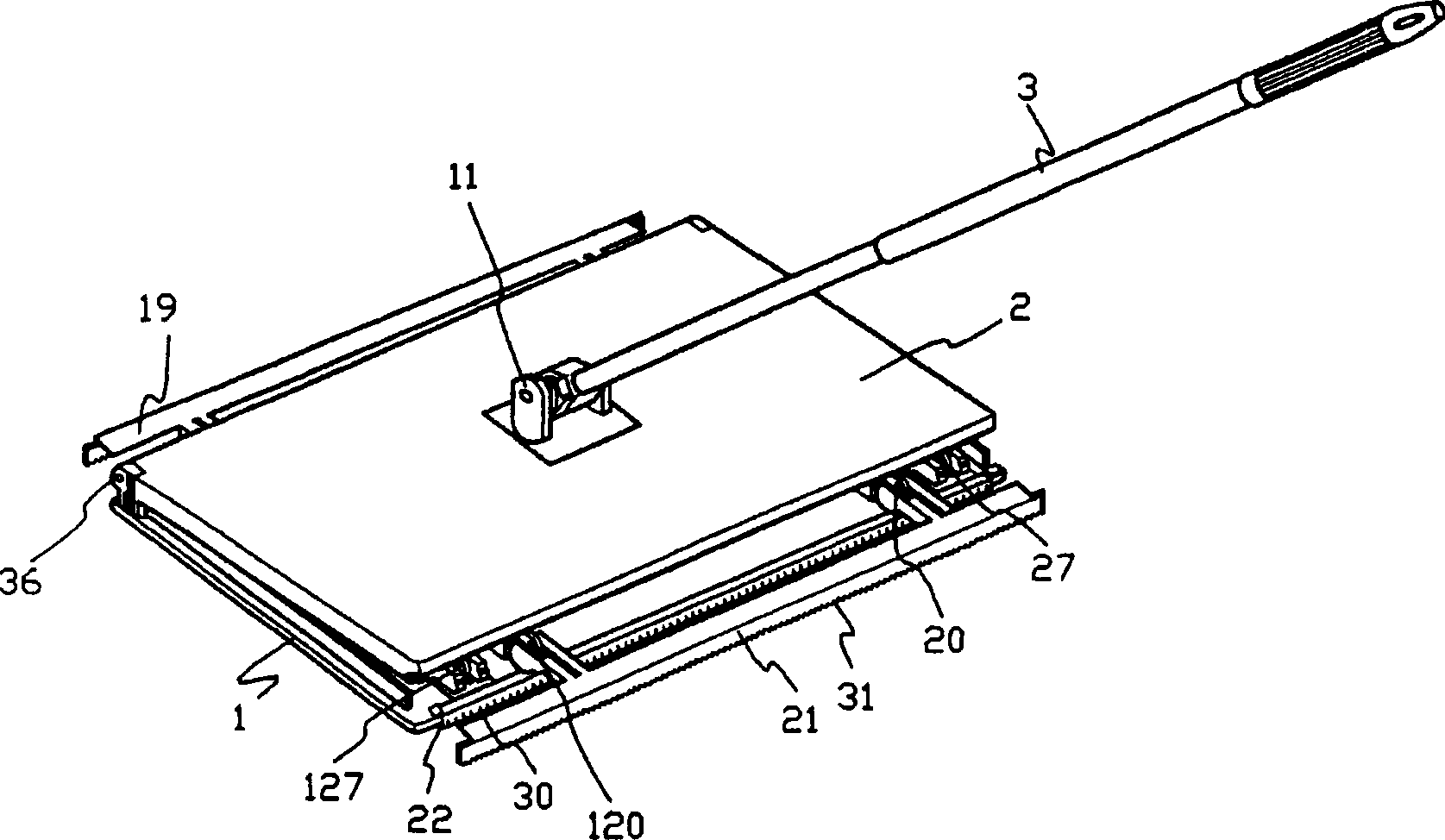

[0027] The cotton rag cleaning machine of the present invention is composed of a lower body (1) assembled with all necessary components, a cover (2) assembled to the lower body, and a handle (3) assembled to the lower body through the cover, Assemble inner clamping members (22, 26) and outer clamping members (19, 21) respectively on both side lateral ends of the lower main body, and clamp cotton rags between the aforementioned inner clamping members and outer clamping members , and the held cotton cloth can be separated.

[0028] figure 1 It is a generalized perspective view of the cleaning machine made of cotton rags according to the present invention. figure 1 It is a perspective view illustrating a cleaning machine in a state where a cotton mop (not shown) is sandwiched between an inner holding member and an outer holding member and a cover (2) is closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com