Steam generator operating on fossil fuel

A technology of steam generators and fossil fuels, applied in steam generation, steam boilers, steam superheating, etc., can solve problems such as complex systems and a large amount of design workload, and achieve low design and production costs, favorable distribution, and reliable pressure balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

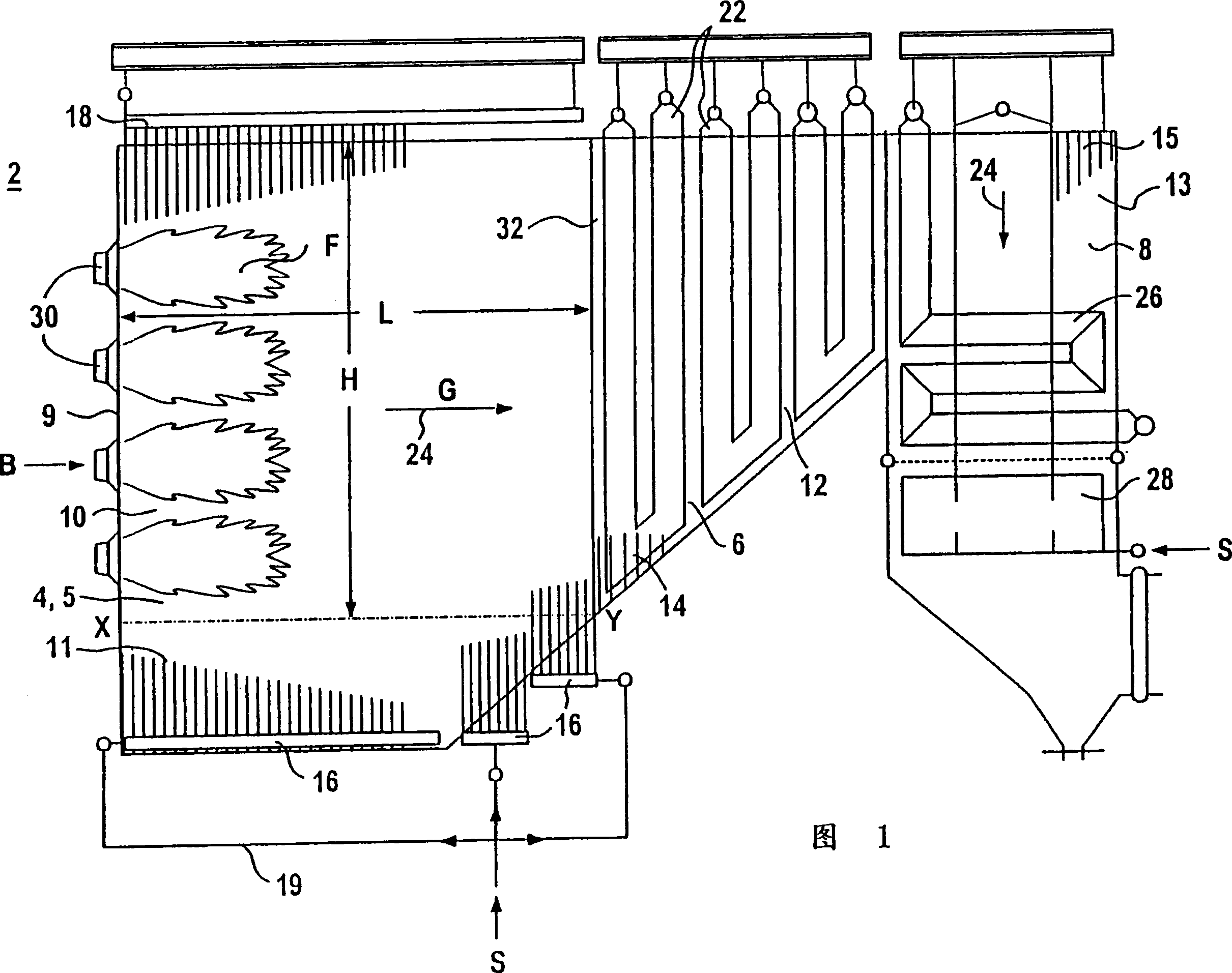

[0042] The steam generator 2 shown in FIG. 1 is assigned to a power plant, not further shown in the figure, which also includes a steam turbine arrangement. The steam produced in the steam generator is used to drive a steam turbine, which in turn drives a generator to generate electricity. The electricity generated by the generator is then fed into an integrated or separate grid. Furthermore, a steam fraction can also be tapped to feed an external process connected to the steam turbine arrangement, which can be a heating process in this case.

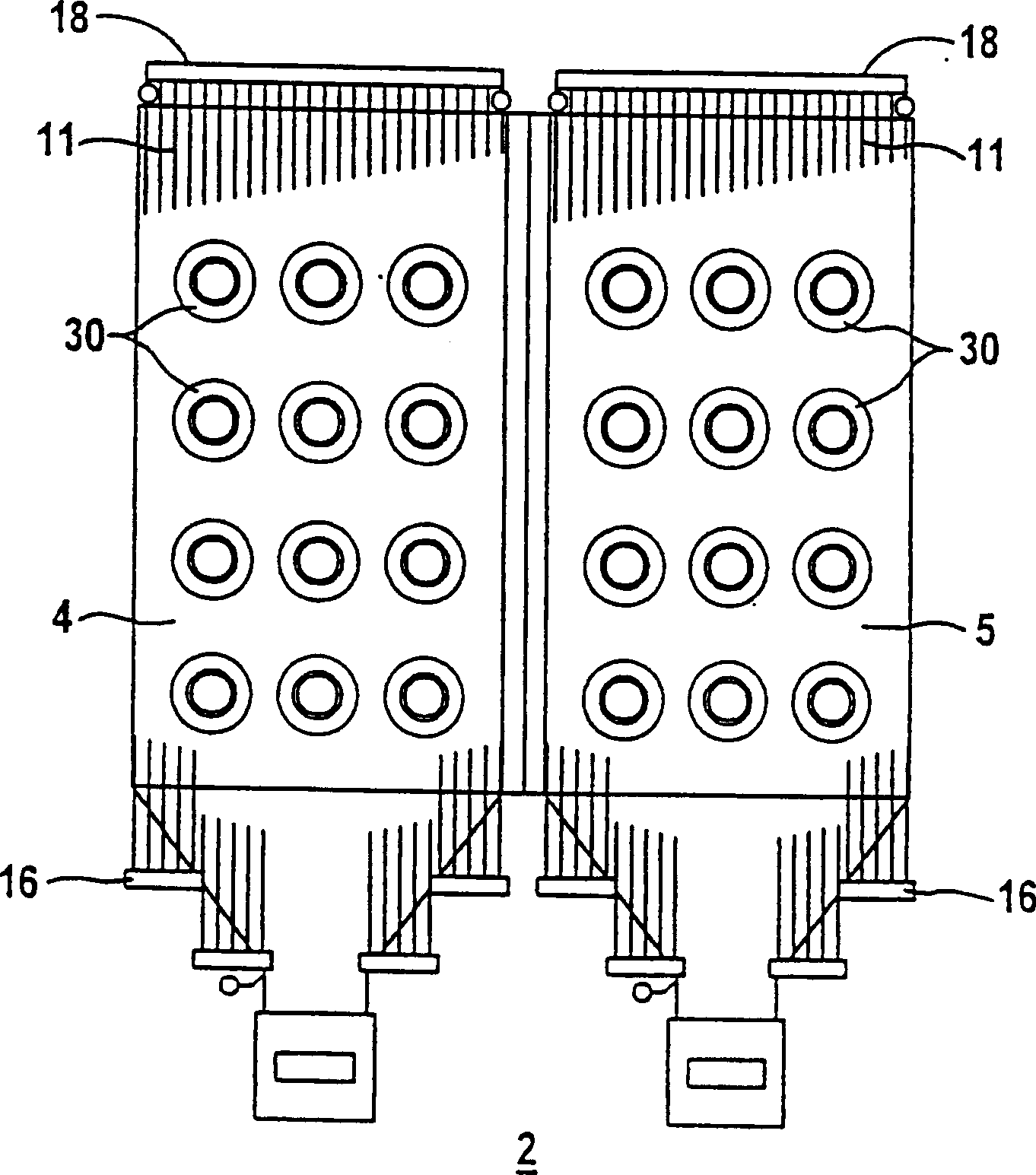

[0043] The steam generator 2 shown in FIG. 1 for heating by burning fossil fuels is advantageously designed as a once-through steam generator. It includes a first horizontal combustion chamber 4 and a second horizontal combustion chamber 5, only one of which can be seen since FIG. 1 shows a side view of the steam generator 2. Downstream of the combustion chambers 4 and 5 of the steam generator 2 in the direction of the hot flue gas fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap