Method and apparatus for controlling thickness uniformity of electroplated layers

A technology of anode device and power supply, which is applied in the field of electrodeposition processing and can solve problems such as copper thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

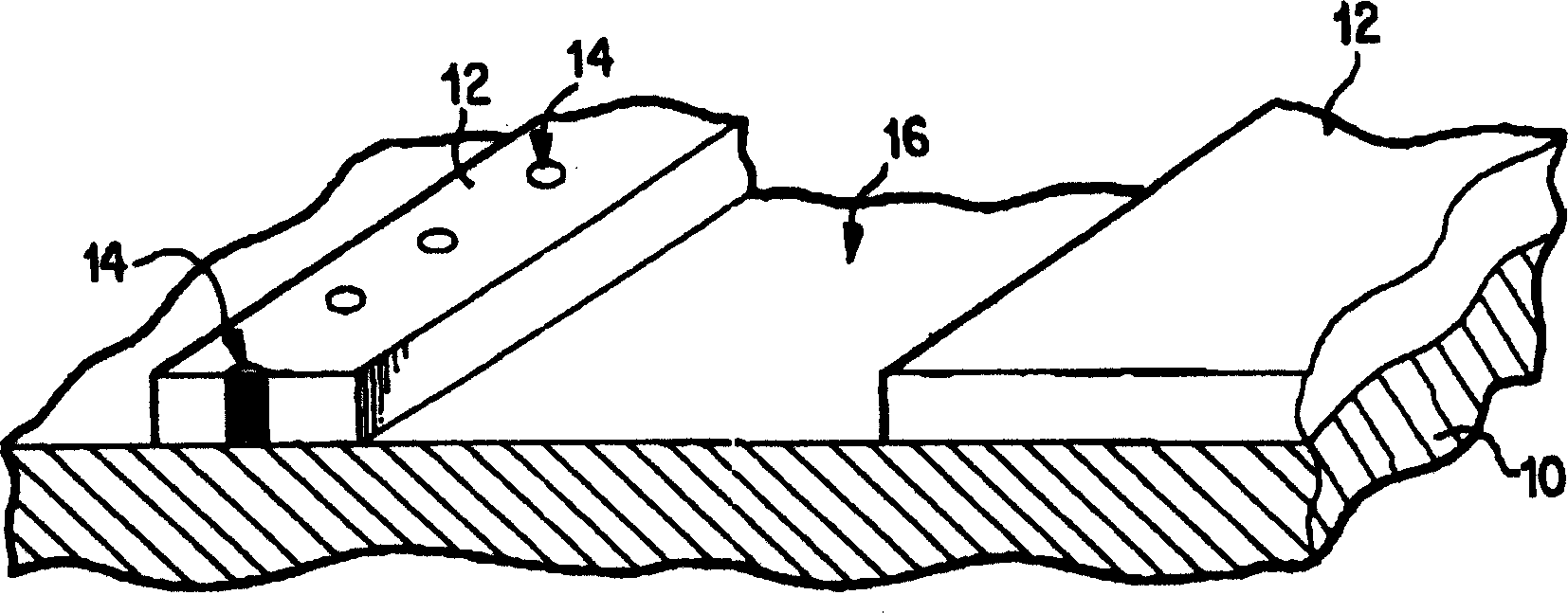

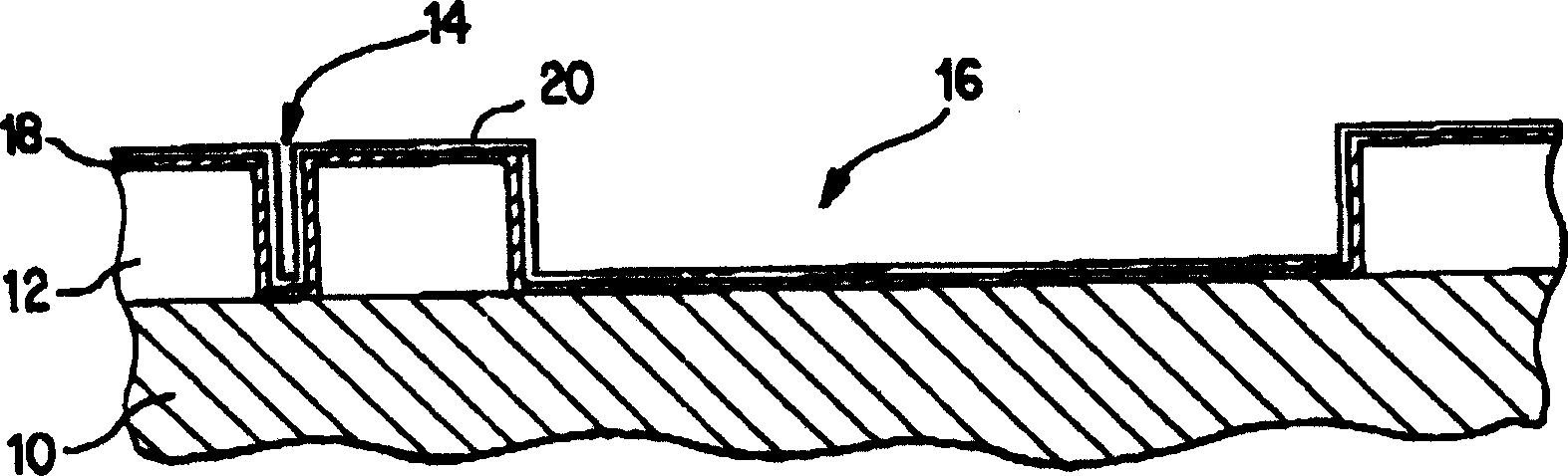

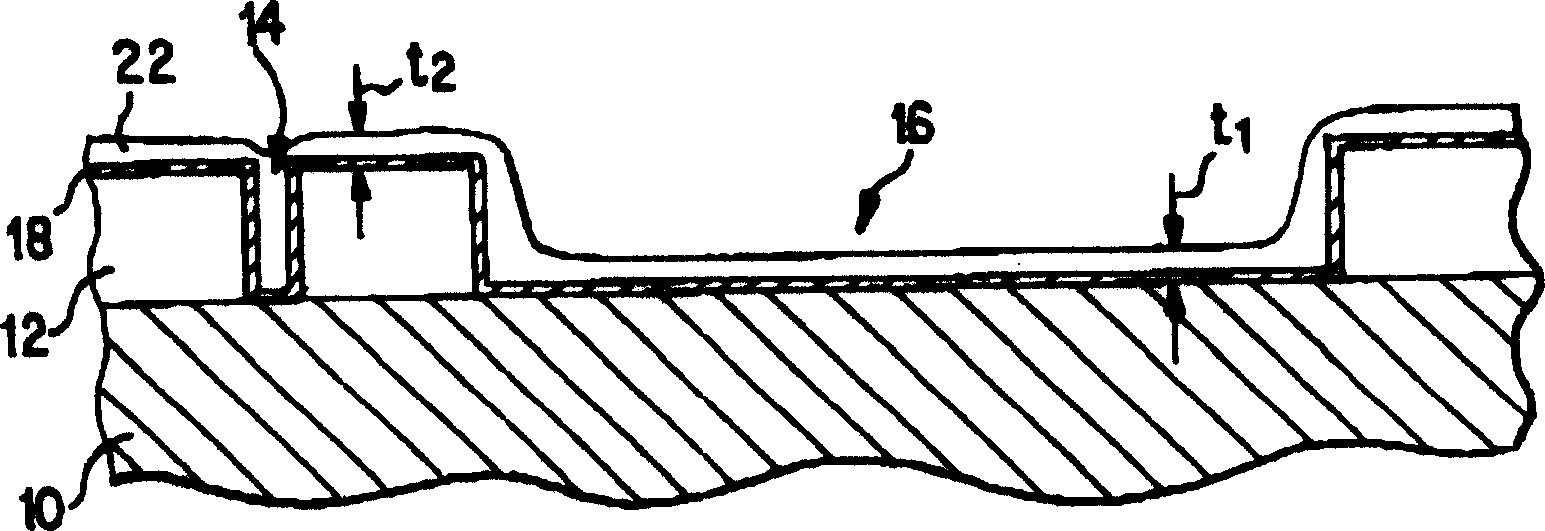

[0049] The present invention provides a method and system for controlling the uniformity of deposition of a layer of conductive material on a semiconductor surface. The invention can be used with ECMD, masked pulse plating, and full surface plating, as well as plating systems that deposit conformal coatings. The deposition process of the present invention advantageously accomplishes the deposition of plating material in numerous cavities, such as trenches, holes, contact holes and the like, on the surface of a semiconductor wafer.

[0050] As is known, during electrodeposition of a wafer surface, the current density applied to the surface is much stronger at the periphery of the surface than in the middle of the surface. In the prior art, this higher current density results in a higher deposition rate of the deposited coating at the periphery of the wafer compared to the center of the wafer. During electrodeposition, using the combination of the perforated plate or a mask and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com