Intensifying diffusion thin-membrane

A technology of film and brightening agent, applied in optics, nonlinear optics, instruments, etc., can solve the problems of the influence of the brightness of the backlight module 20 and the high shading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

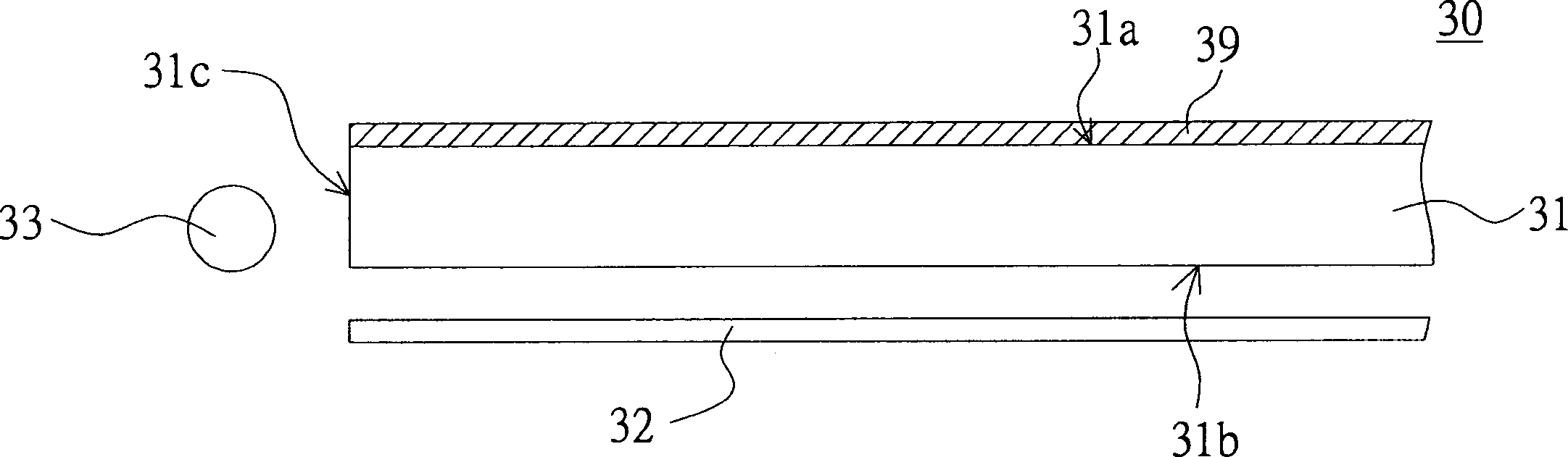

[0027] The invention is to provide a light-enhancing diffusion film which can be used in a backlight module. The light-enhancing diffusion film is arranged on the light guide plate of the backlight module, and when light passes through the light-enhancing diffusion film, the light passing through the light-enhancing diffusion film will diffuse and enhance the light to become highly uniform light. By using this light-enhancing diffusion film, the use of diffusion sheets and prism sheets in traditional multilayer optical films can be reduced, and the brightness quality of the backlight module can be improved.

[0028] Such as image 3 As shown, the light-increasing diffusion film according to the preferred embodiment of the present invention is applied to a partial cross-sectional view of a lateral backlight module. in image 3 Among them, the lateral backlight module 30 at least includes a light guide plate 31, a reflective sheet 32, a light source 33 and a light-enhancing diffusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com