Connecting pipe of drinking machine

A technology for connecting pipes and drinking fountains, applied in applications, home appliances, kitchen appliances, etc., can solve the problems of increased product cost, toxic and odorous silicone tubes, and achieve the effect of overcoming easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

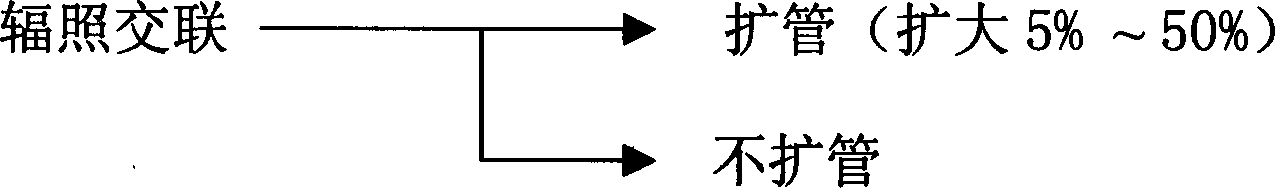

Method used

Image

Examples

Embodiment 1

[0026] Use high-pressure polyethylene resin to add 10% ethylene-vinyl acetate copolymer, mix through the above mixing process, and then squeeze the tube on a single-screw extruder to obtain a rubber tube with an inner diameter of 12 mm and a wall thickness of 1.5 mm. After the rubber hose is subjected to the above-mentioned electron irradiation process and expanded into shape, a rubber hose with a tube expansion ratio of 10% is finally obtained.

Embodiment 2

[0028] Adding 30% high-pressure polyethylene to low-pressure polyethylene resin, through the above-mentioned process, can finally produce a rubber hose with a tube expansion ratio of 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com