Portable full digital direct testing universal hardness meter

An all-digital, hardness tester technology, applied in the direction of testing material hardness, which can solve the problems of poor accuracy, poor consistency, inability to perform, and the inability of handheld Shore hardness testers to obtain test results online, achieving a high degree of digitization and versatility Strong, wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

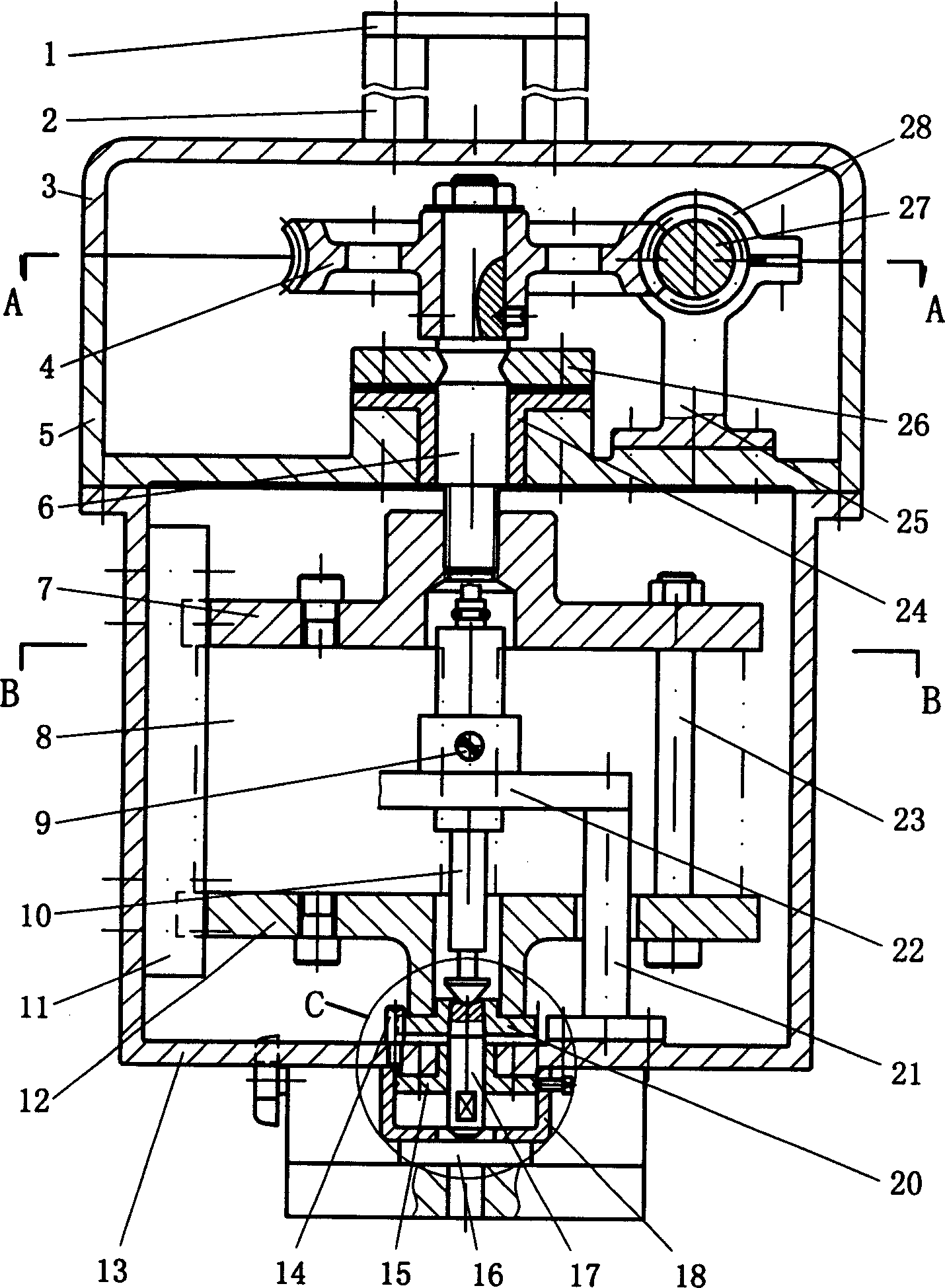

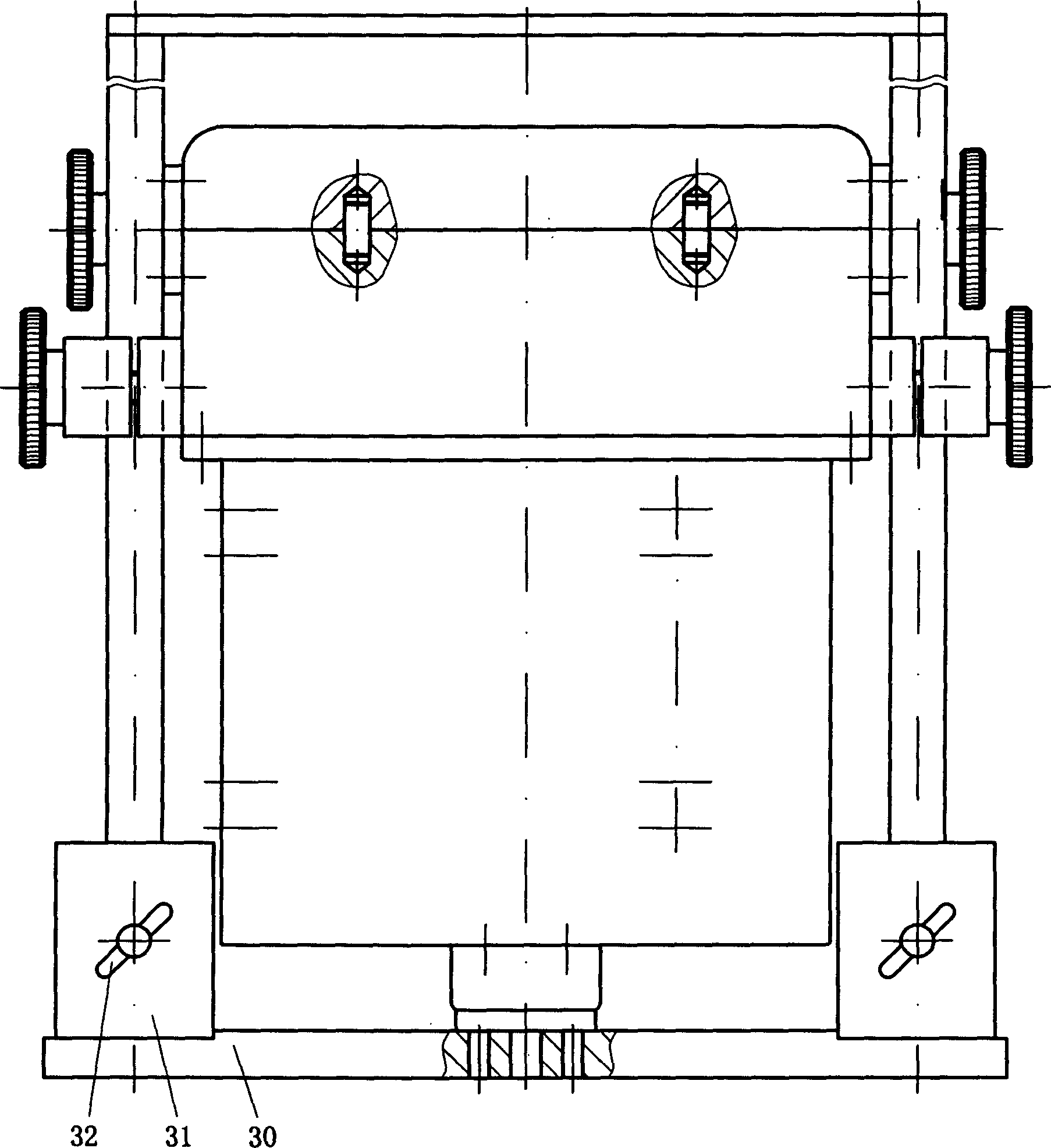

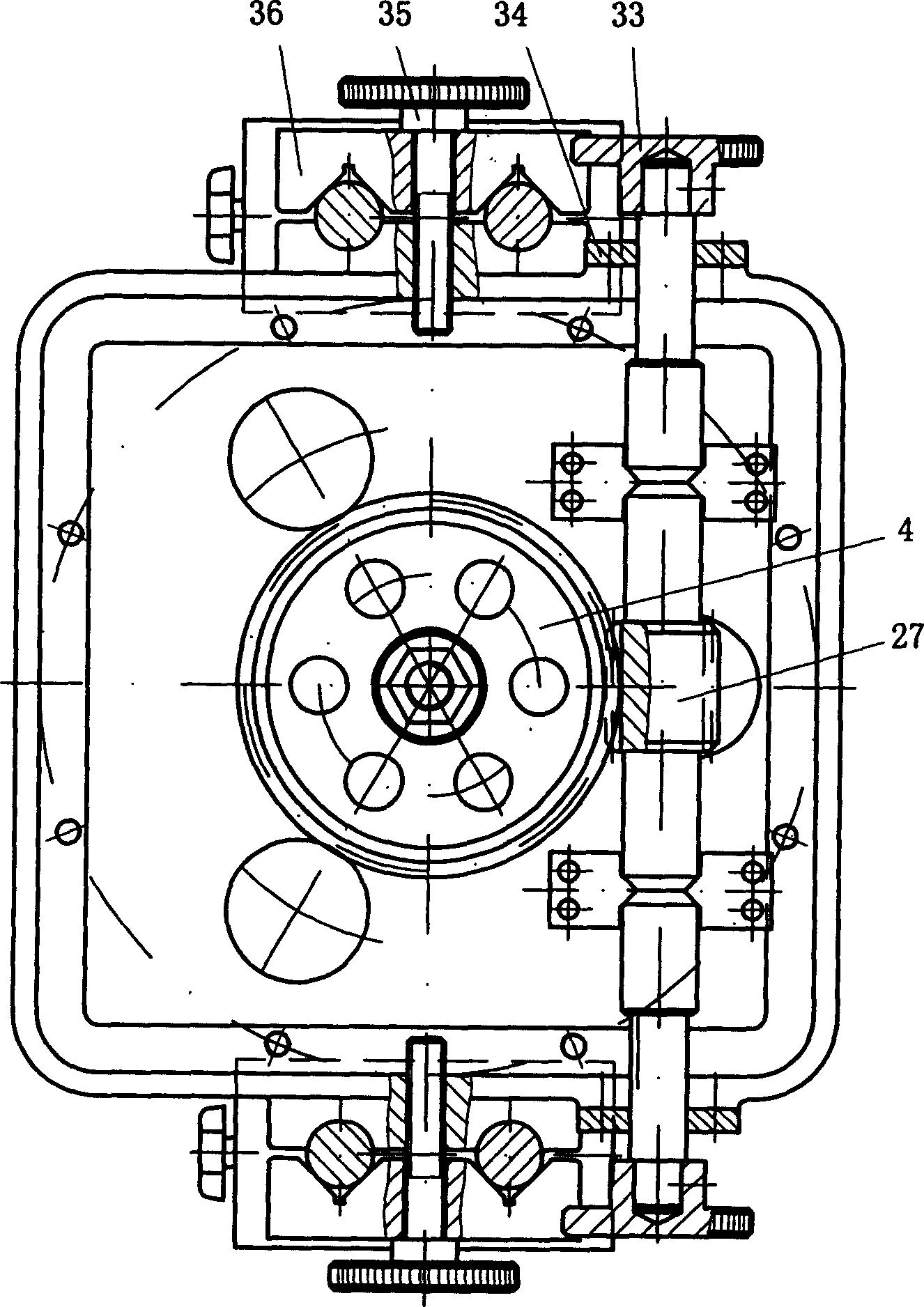

[0019] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

[0020] Figure 1-12 Among them, the names corresponding to each drawing number are: 1-beam, 2-column, 3-top cover, 4-worm gear, 5-frame, 6-worm gear shaft, 7-force sensor seat, 8-force sensor, 9 -set screw, 10-displacement sensor, 11-guide rail, 12-pressure plate, 13-extension sleeve, 14-stop pin, 15-pressure head bushing, 16-sample, 17-pressure head, 18-sheath , 20-pressure head seat, 21-pillar, 22-support plate, 24-shaft sleeve, 25-worm screw lower support, 26-shaft support, 27-worm screw, 28-worm screw upper support, 30-support bottom plate, 31-magnetic Seat, 32-magnetic switch, 33-handwheel, 34-connecting cover plate, 35-locking handwheel, 36-locking plate, 37,38-amplifier, 39-clock driver, 40,41-sampling and holding device ( S / H) and analog / digital (A / D) converter, 42-random access memory (RAM), 43-keyboard, 44-microcomputer, 45-display, 46,47-V block,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com