Automatic detection method and device for neps and impurities in sliver

An automatic detection device and sliver technology, which is applied in the direction of optical detection of defects/defects, etc., can solve problems such as large influence, easy fatigue, and high labor intensity, and achieve low labor intensity, high detection efficiency, and improved yarn formation and textile quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Reference attached figure 1 , 2 , 3 describes an embodiment of the present invention.

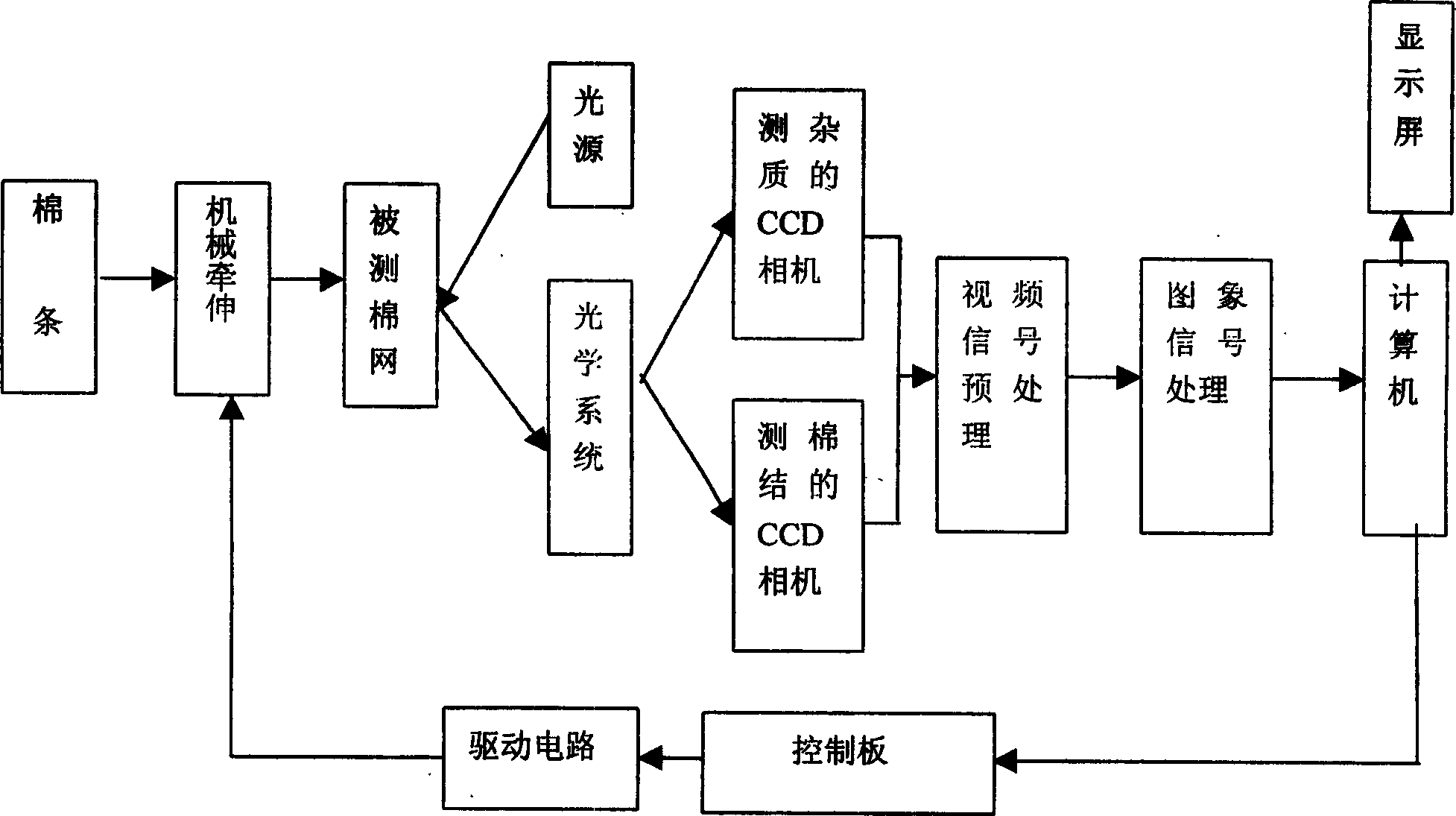

[0017] An automatic detection method for neps and impurities in cotton sliver:

[0018] ① Draft the sliver to form a cotton net with uniform width and uniform thickness;

[0019] ② Irradiate the cotton net evenly with light;

[0020] ③Using an area-scan CCD camera to capture images of the cotton net on the black and white backgrounds;

[0021] ④ Apply image processing technology to pre-process the image signal captured by the area array CCD camera;

[0022] ⑤The pre-processed image signal is sent to the computer, and the neps and impurities on the cotton web are classified and counted through the computer to output the data.

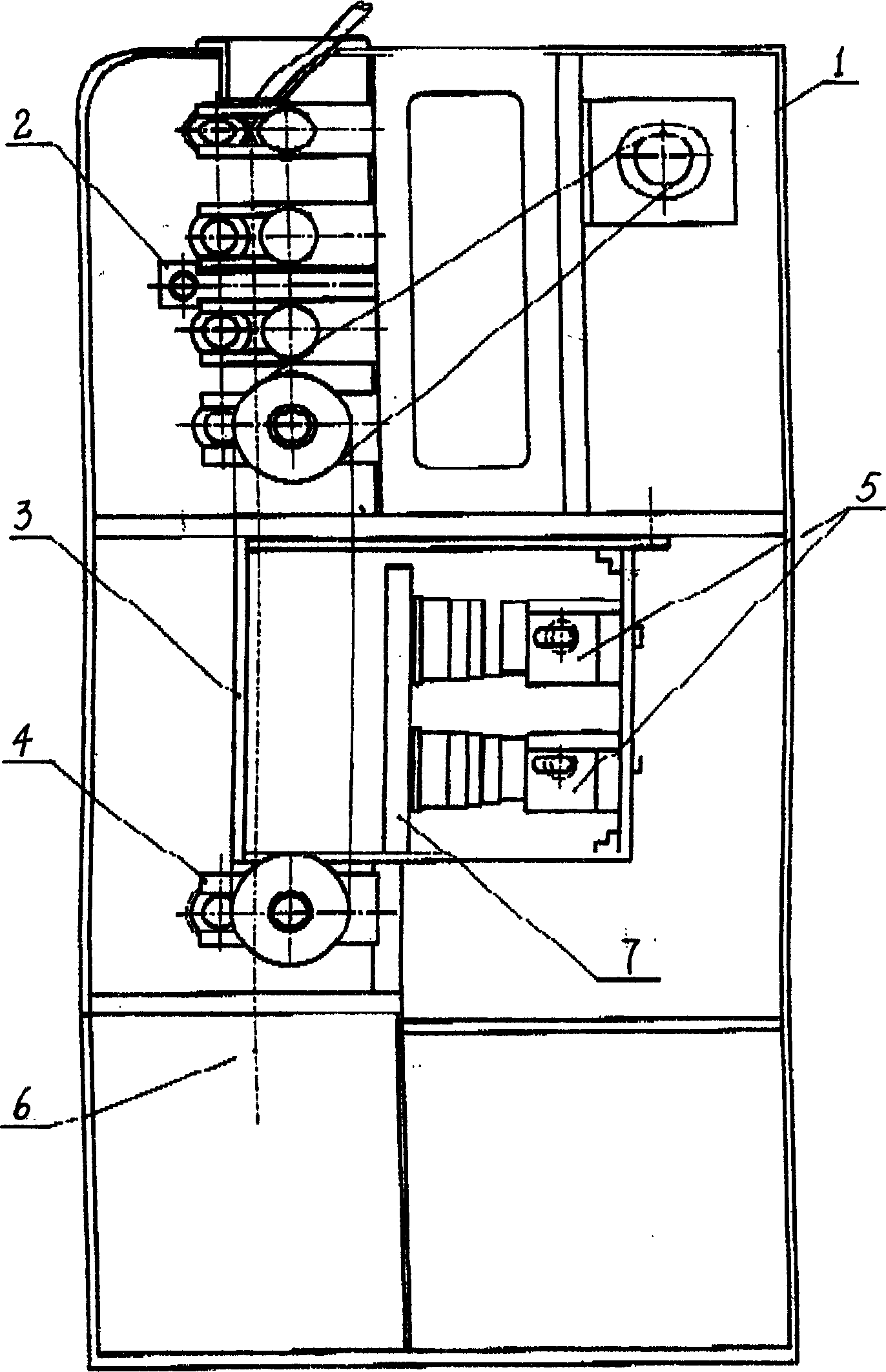

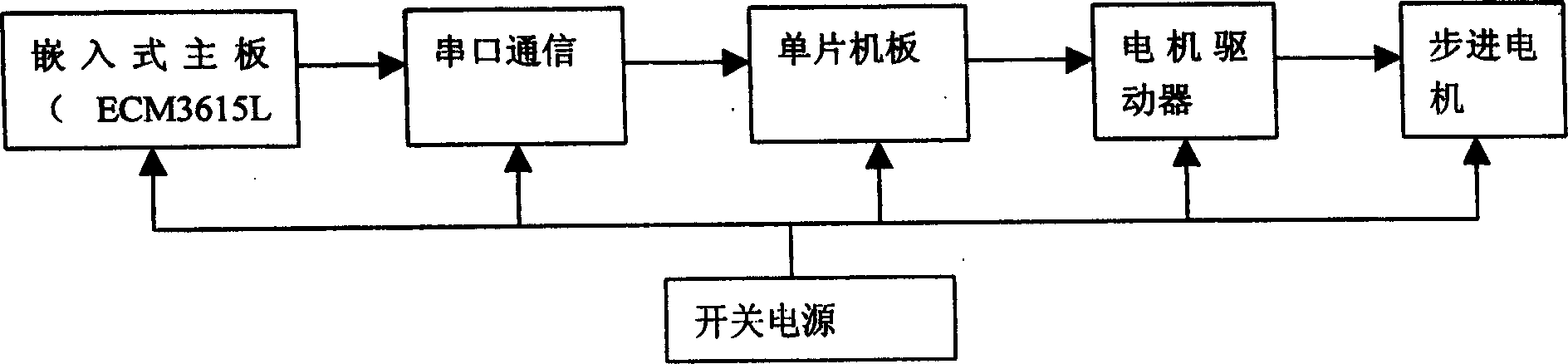

[0023] An automatic detection device for neps and impurities in cotton sliver, in which a sliver drafting mechanism (2), a black and white bottom plate (3), a cotton web drafting mechanism (4) and a cotton web are vertically arranged in the shell (1) The collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com