Technology of preventing slantingly suck rod and oil pipe containing polymer of beam unit

A technology for pumping wells and anti-eccentric wear, which is applied to drilling equipment, earthwork drilling, drill pipes, etc. It can solve the problems of increasing the proportion of sucker rod breakage and moving up and down, so as to prolong the pump inspection cycle and slow down the downward resistance Amplifies, eliminates the effect of lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

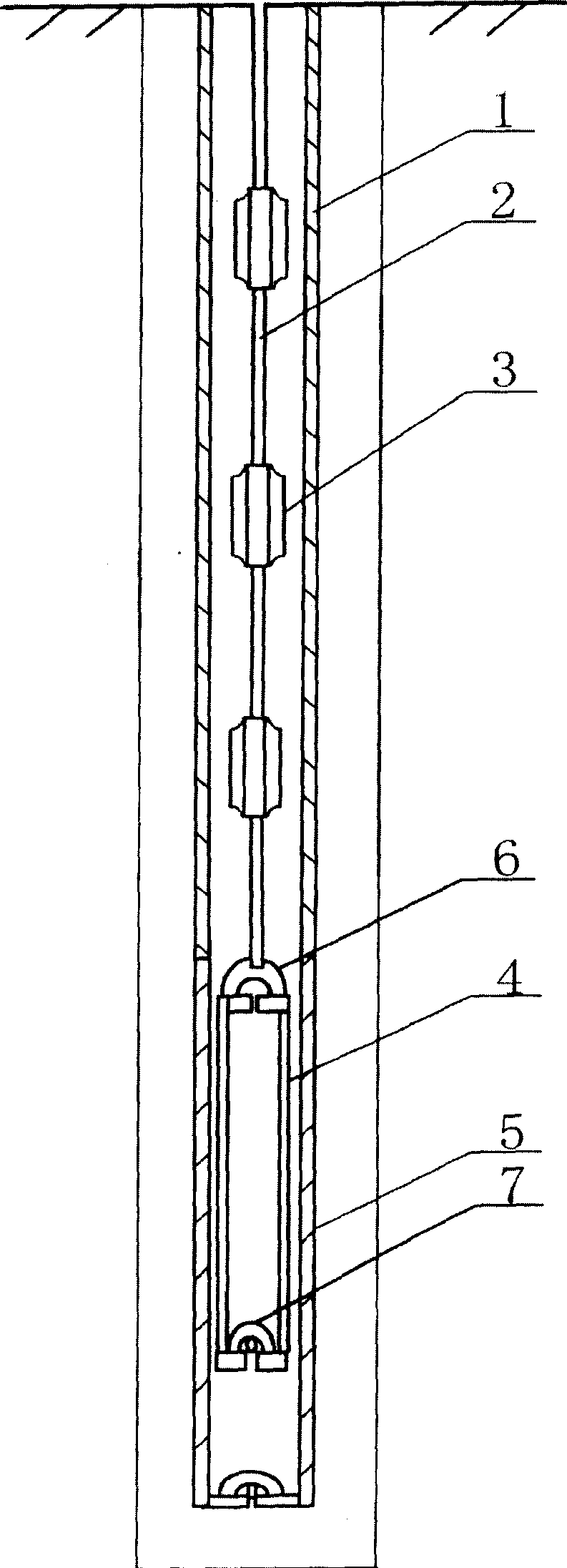

[0027] Embodiment 1. The anti-eccentric wear process implemented on the North 1-51-535 of the polymer-containing pumping unit comprises the following steps:

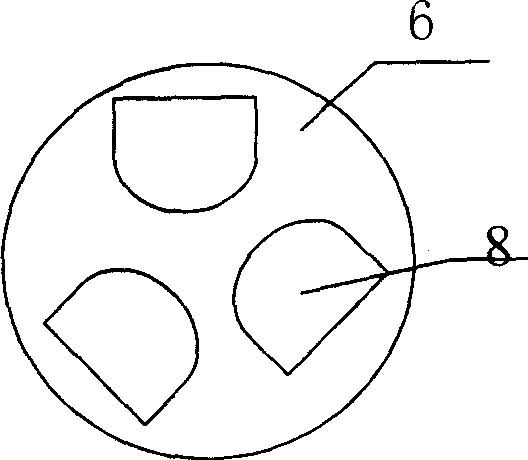

[0028] (1) A centralizing ring 5 is installed at 20cm below the coupling of each sucker rod 4 in the whole well, and the rod diameter is unified up and down. (2), a. Change the plunger 2 assembly of the oil well pump into a single floating valve group, that is, cancel the upstream floating valve group, and at the same time change the four-hole structure of the oil outlet of the upper valve cover 3 into three circular arcs The structure of the groove 1; b. Shorten the length of the plunger 2: the length of the plunger 2 is shortened from the original 1200mm to 900mm; c. The pump gap is enlarged: the radial gap between the plunger 2 and the pump barrel 6 is enlarged from 20μm-70μm to 220 μm. (3) Rotate the sucker rod regularly. After adopting this technical scheme and running for 1035 days, no rod breakage occurred.

Embodiment 2

[0029] Embodiment 2, the anti-eccentric wear process implemented on 1-63 in the polymer-containing pumping well comprises the following steps:

[0030] (1) A centralizing ring 5 is added at 25cm below the collar of each sucker rod 4 in the whole well, and the rod diameter is unified. (2), a. Change the plunger 2 assembly of the oil well pump into a single floating valve group 7, that is, cancel the upstream floating valve group, and at the same time change the four-hole structure of the oil outlet of the upper valve cover 3 into three circles The structure of the arc groove 1; b. Shorten the length of the plunger 2: the length of the plunger 2 is shortened from the original 1200mm to 900mm; c. The pump gap is enlarged: the radial gap between the plunger 2 and the pump cylinder 6 is enlarged from 20 μm to 70 μm to 120 μm. (3) Rotate the sucker rod regularly. After adopting this technical scheme and running for 1035 days, no rod breakage occurred.

Embodiment 3

[0031] Embodiment 3. The anti-eccentric wear process implemented on the North 1-42-B 55 well of the polymer-containing pumping unit includes the following steps:

[0032] (1), a centralizing ring 5 is installed at 23cm below the collar of each sucker rod 4 in the whole well, and the diameter of each sucker rod in the whole well is small at the top and large at the bottom. (2), a. Change the plunger 2 assembly of the oil well pump into a single floating valve group 7, that is, cancel the upstream floating valve group, and at the same time change the four-hole structure of the oil outlet of the upper valve cover 3 into three circles The structure of the arc groove 1; b. Shorten the length of the plunger 2: the length of the plunger 2 is shortened from the original 1200mm to 900mm; c. The pump gap is enlarged: the radial gap between the plunger 2 and the pump cylinder 6 is enlarged from 20 μm to 70 μm to 150 μm. (3) Rotate the sucker rod regularly. After adopting this technical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap