Device and method for precision measuring focal length of long-focus lens

A technology of precise measurement and long focal length, applied in the field of strong laser, can solve the problems of difficult automation, adjustment and installation, troublesome use, manual adjustment, etc., and achieve the effect of easy automation, less conversion links and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

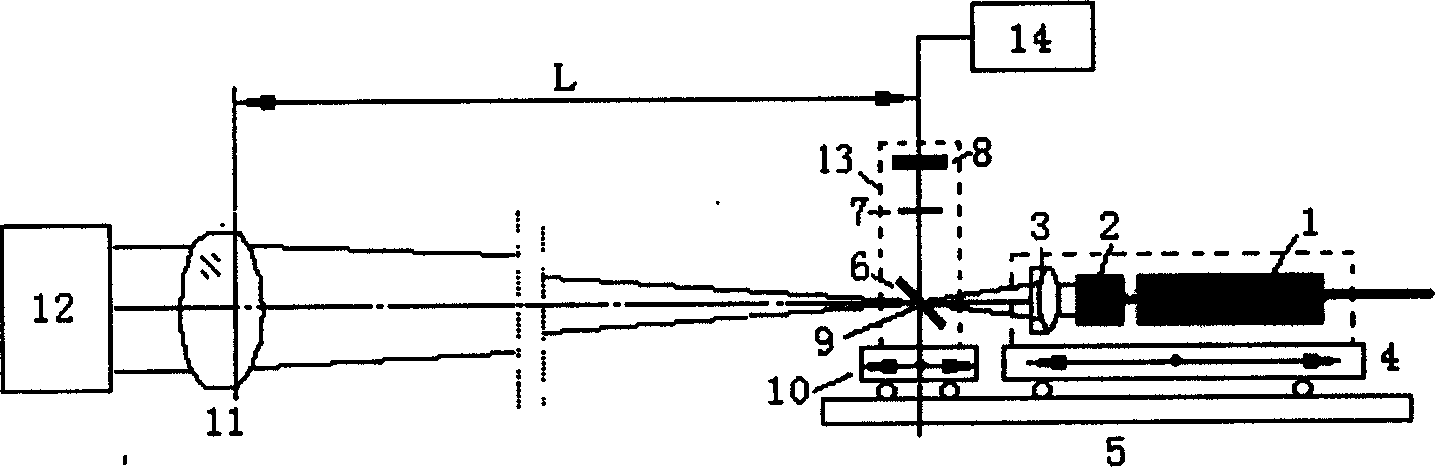

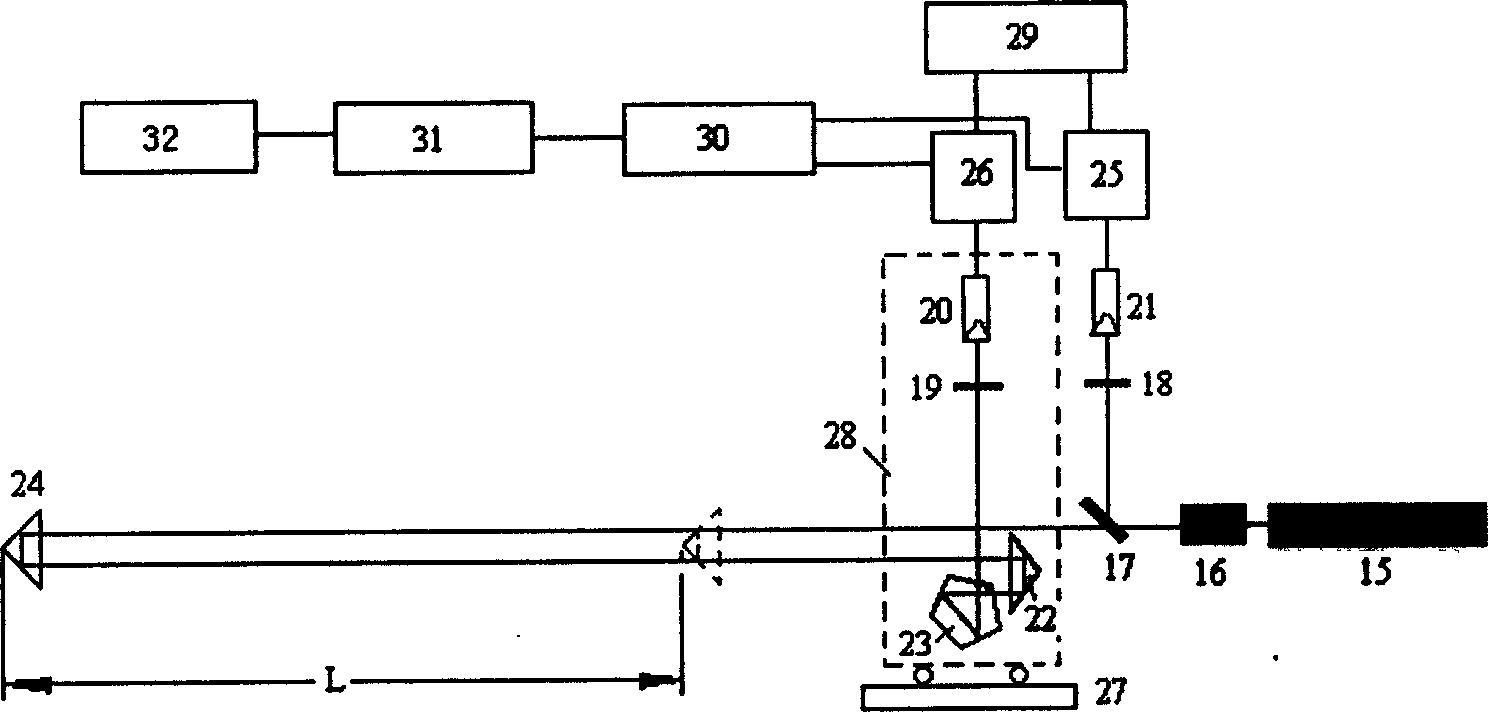

[0019] The focal length precision measuring device of long focal length lens such as figure 1 As shown, the laser light drawn by a strong laser source or other laser light 1 with the same frequency is appropriately expanded by the beam expander 2 and becomes parallel light, then converged by the lens 3, and then exits through the large-diameter lens 11 under test. The laser source 1 and the lens 3 of the beam expander 2 are all fixed on the slide plate 4 . The slide plate can move back and forth along the direction of the optical axis along a short guide rail 5 (for example, 500 mm). When the outgoing light of the measured lens 11 is adjusted to be parallel light, the position of the focal point 9 must be the correct position of the measured focal point. The main body of the parallel light accurate determination device 12 is a parallel flat crystal with suitable precision and size, observe the interference of its reflected light (it should be completely black or fully bright ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com