Laminate sheath type battery

A technology for batteries and encapsulation shells, applied in the field of laminated sheet encapsulated batteries, can solve problems such as inability to prevent offset or movement, inability to prevent internal short circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

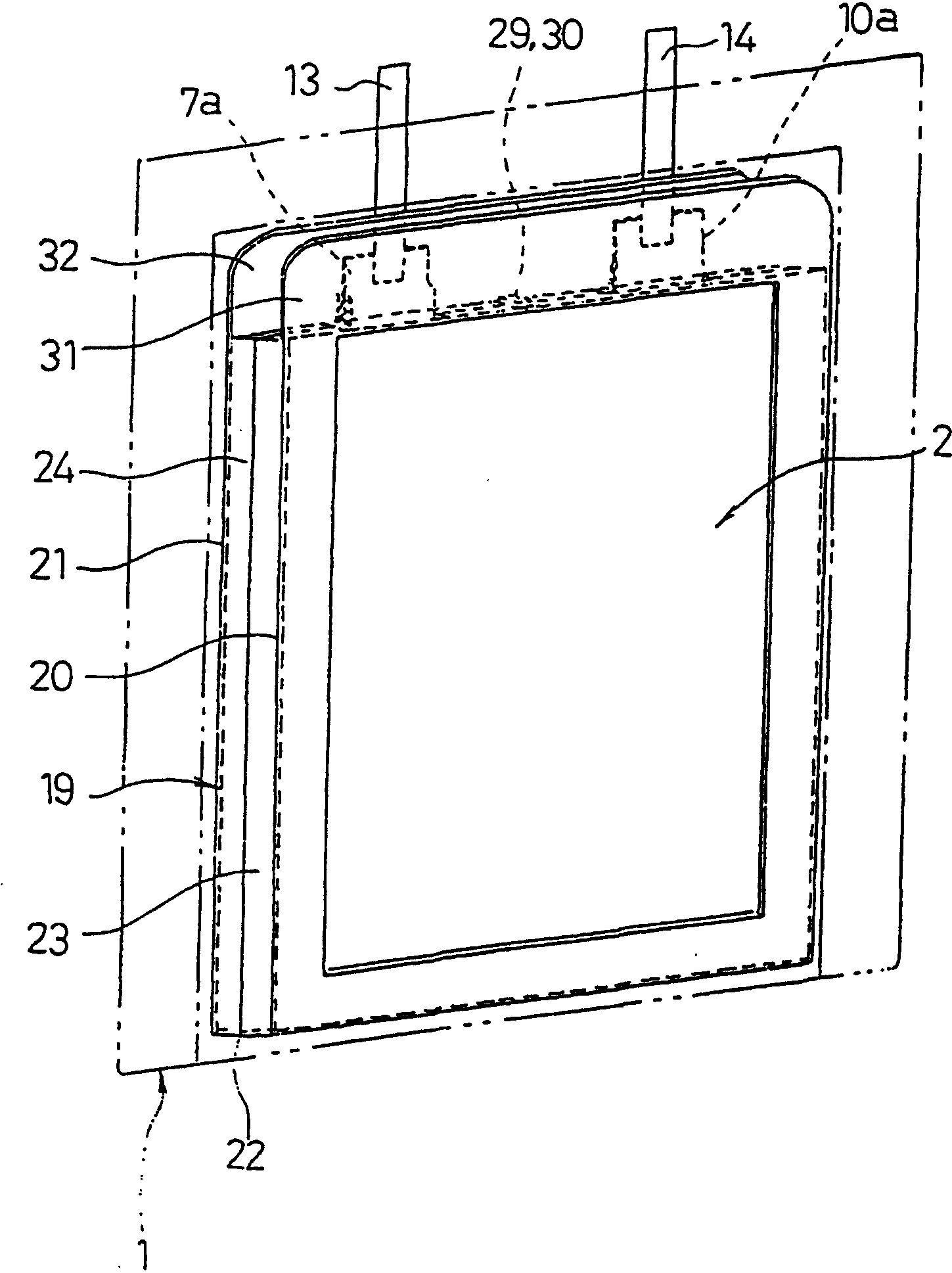

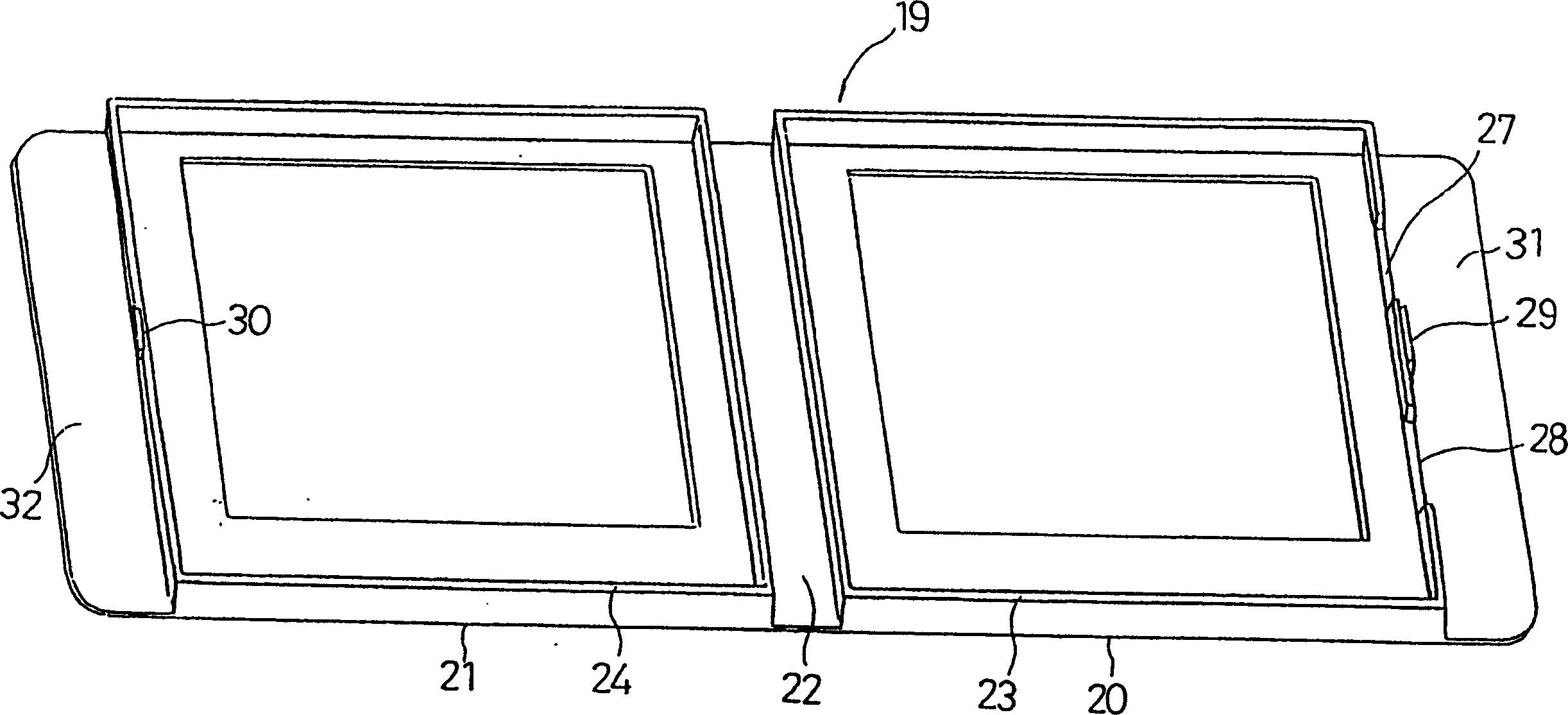

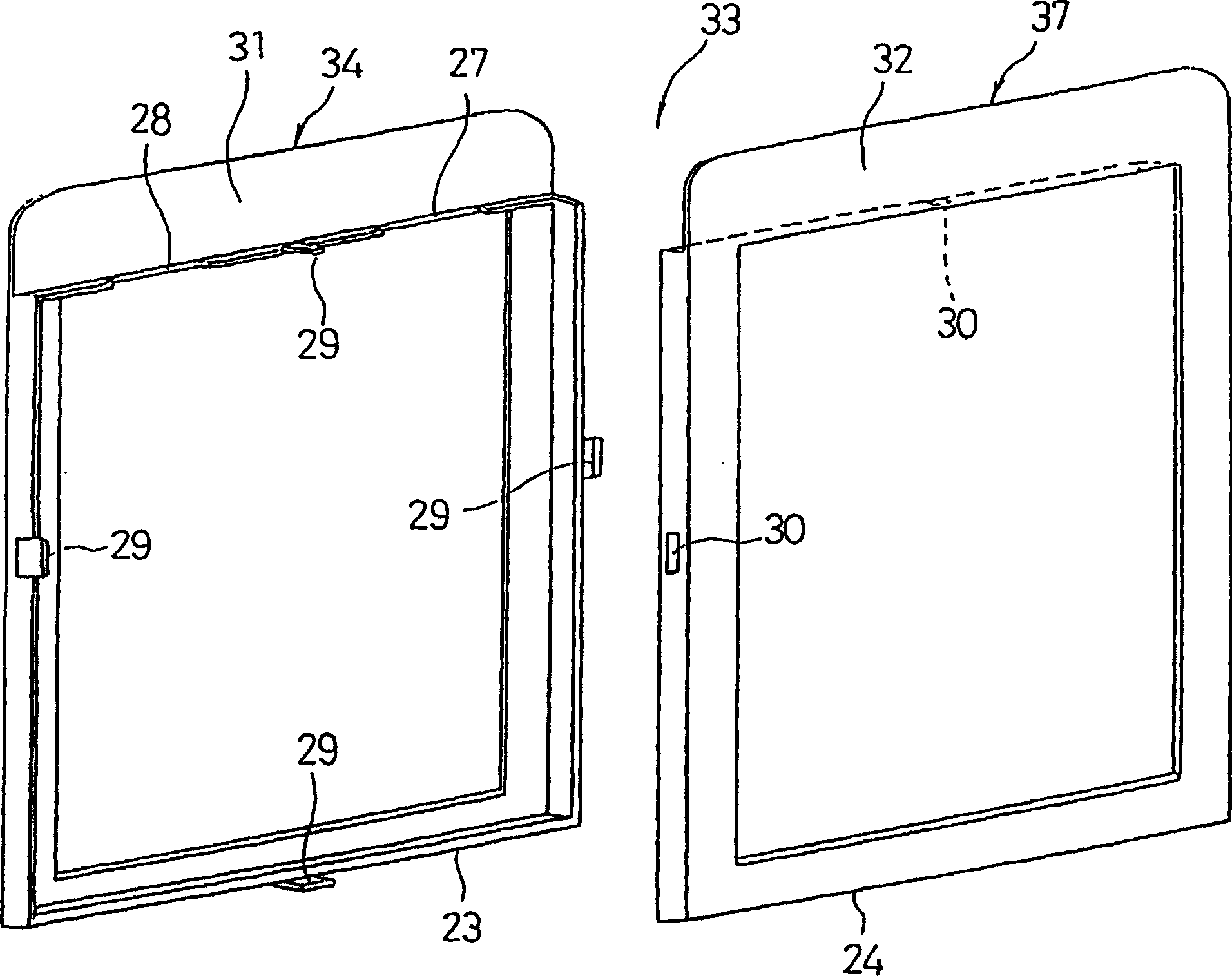

[0076] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. The unit electrode group 3 used in the various embodiments described below, the laminated electrode group 2 and the packaging case 1, 18 after it is stacked, and Figure 35 to Figure 40 It is the same as the existing one that has been explained. but Figure 37 The unit electrode group 3 used in the laminated sheet package type battery according to the embodiment of the present invention is shown. First, before describing each embodiment, for the unit electrode group 3 of the sheet-shaped or film-shaped polymer electrolyte constituting the flat laminated electrode group 2, refer to Figure 36 and Figure 37 Provide specific supplementary instructions.

[0077] The unit plate group 3 is formed by stacking a film-shaped or sheet-shaped positive electrode plate 9, a diaphragm 12, and a film-shaped or sheet-shaped negative electrode plate 4. On both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com