Flow field adaptation type demister

A mist eliminator and adaptive technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of small pressure loss, achieve low energy consumption, reduce manufacturing, and good defogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

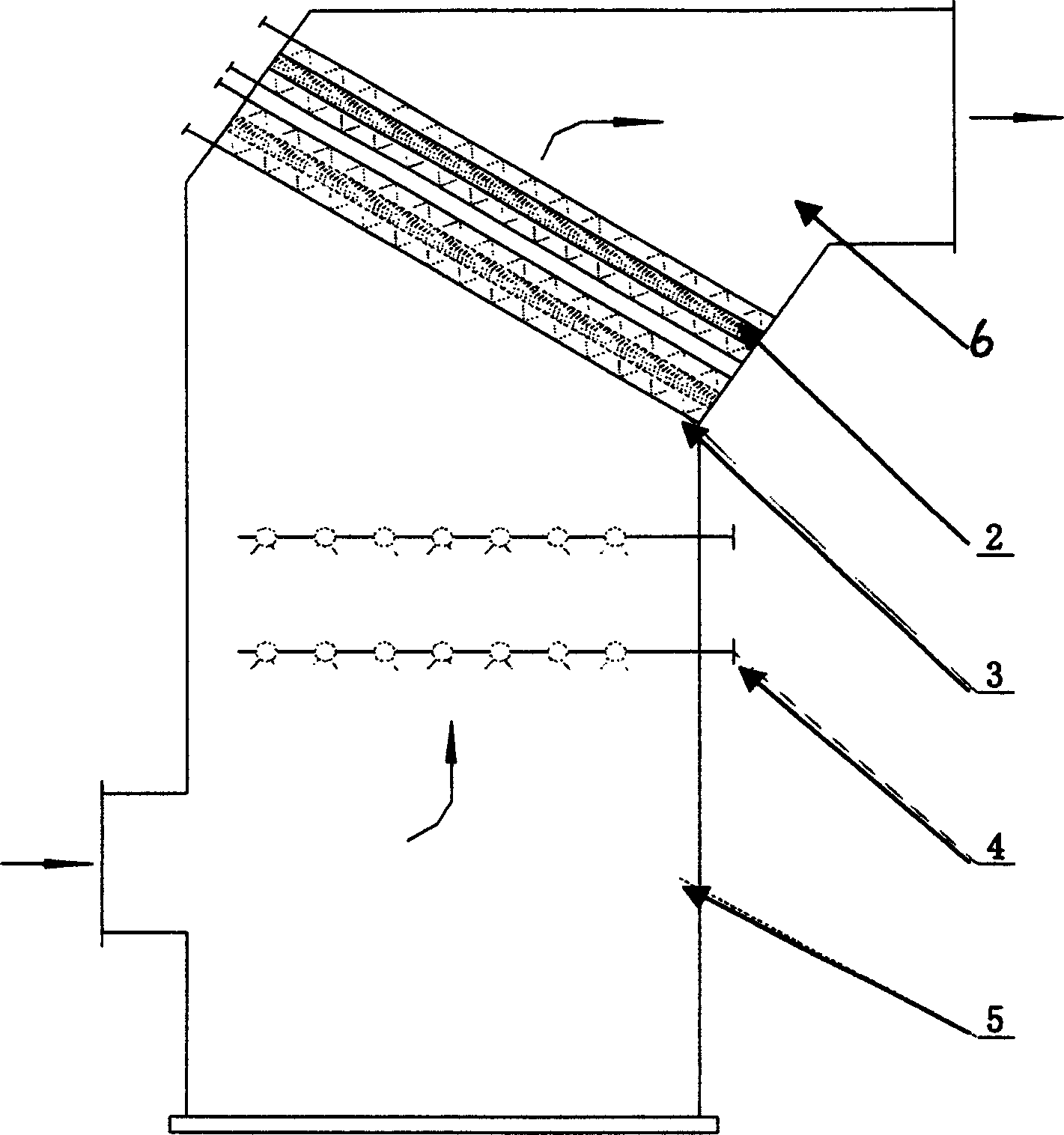

[0013] The flow field adaptable demister of the present invention considers the fluid characteristics of the demister element 2 and the fluid characteristics of the absorption tower slurry spray device 4, the flushing device 3, and the outlet flue 6 before and after it. The fluid characteristics of the mist element are used to form a flow field structure that is most conducive to the function of the demister, and there is no need to change the fluid characteristics of the front and rear devices in order to meet the requirements of the demister. The air inlet of the flow field adaptable demister is located downstream of the slurry spray device 4 of the absorption tower, and the air outlet communicates with the outlet flue 6 of the absorption tower; The upstream and downstream of the demisting element 2 are respectively equipped with flushing devices 3 .

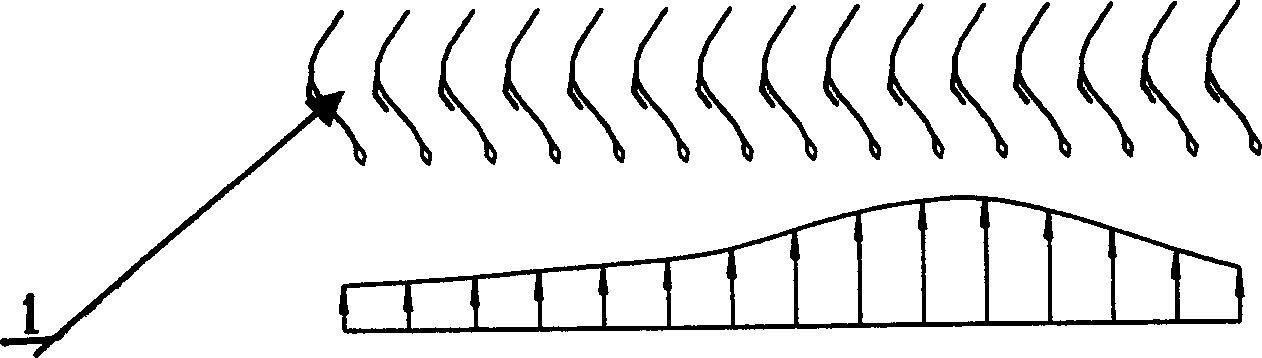

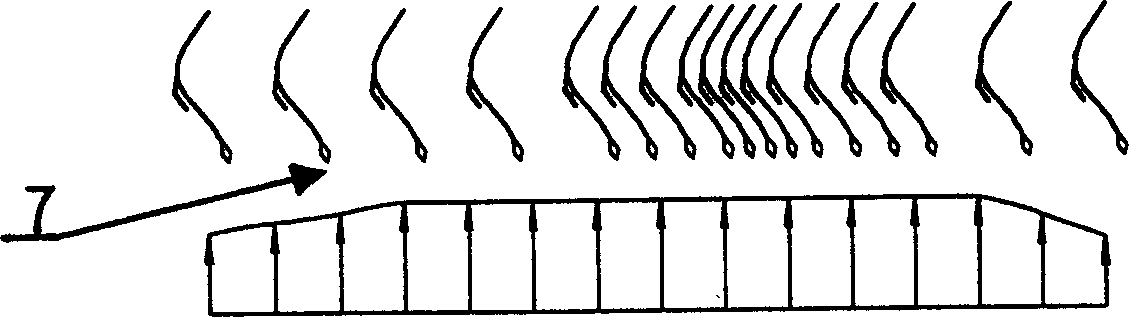

[0014] The baffles 1 in the defogging element 2 are distributed unevenly and in different forms along the flow section, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com