Automatic method of measuring temperature for coke furnace and system of measuring temperature

An automatic, coke oven technology, applied in coke ovens, thermometers, measuring devices, etc., can solve the problems of large sensor accuracy error, high cost, large human error in measurement accuracy, etc., to achieve high measurement reliability, reduce impact, and solve safety problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

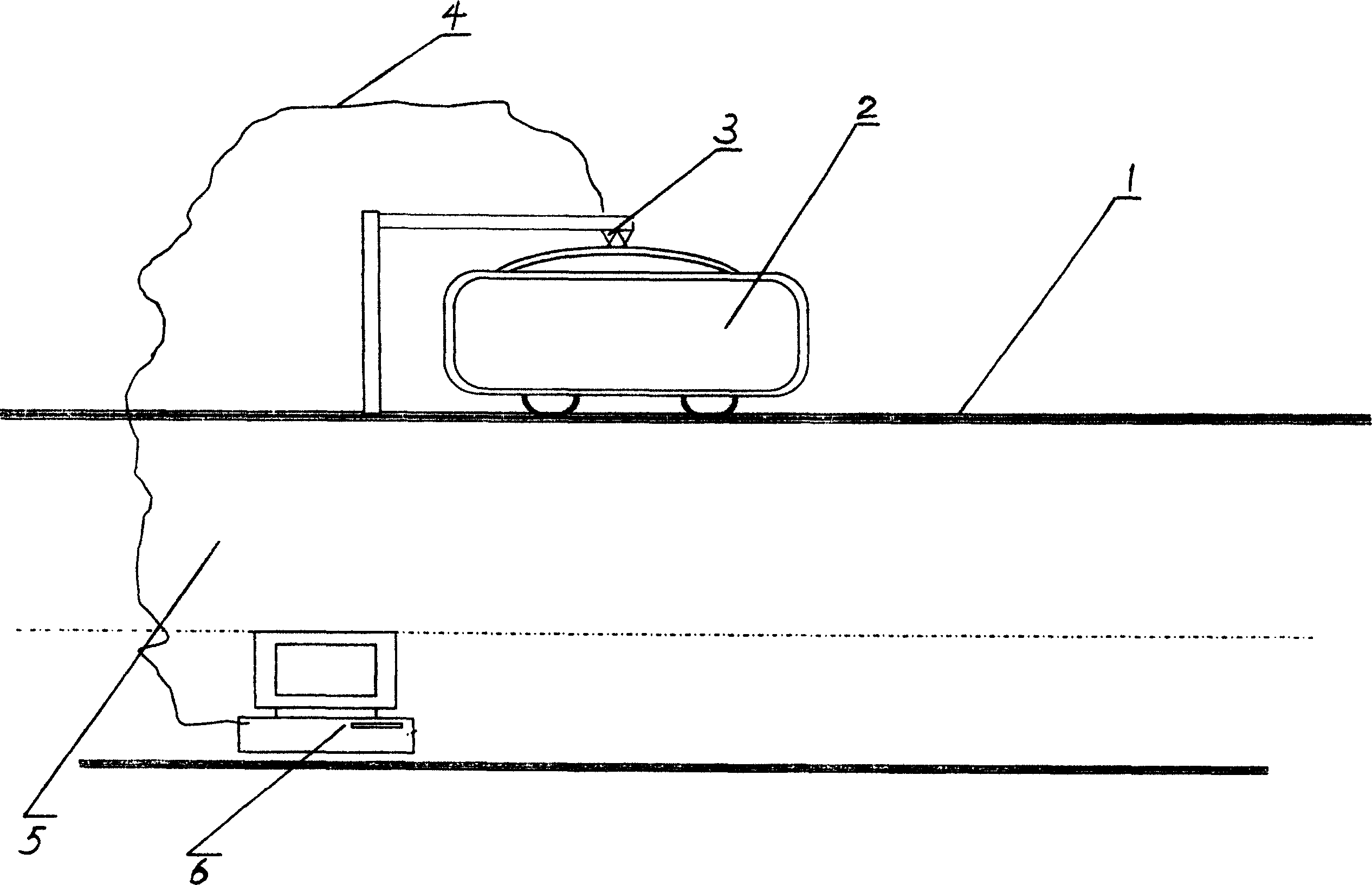

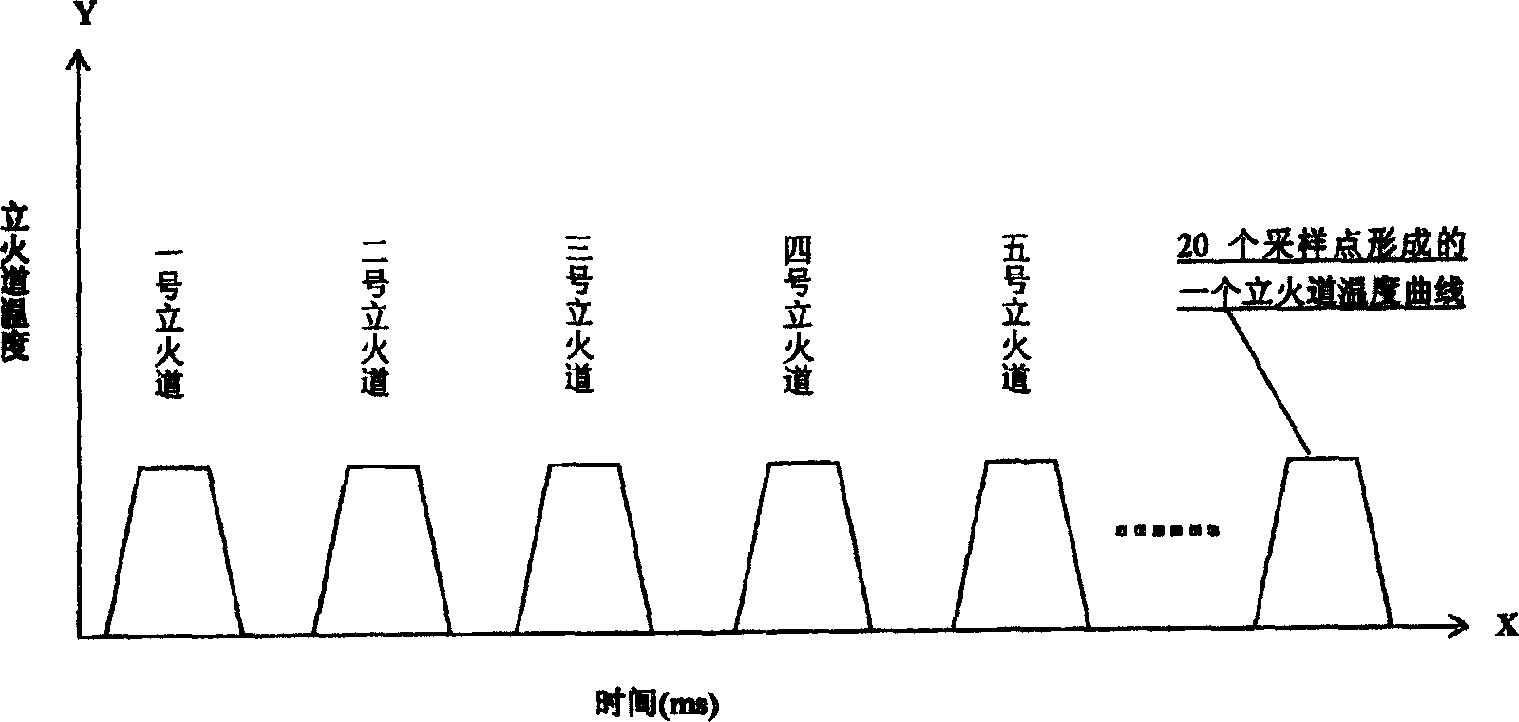

[0024] Embodiment 1: as figure 1 , 2 , 3 and 5, a coke oven automatic temperature measurement system is composed of a temperature measurement track 1, an automatic temperature measurement device 2, a brush type communication head 3 and a host computer 6, and the temperature measurement track 1 is set in the coke oven 5 The circular track outside the furnace surface coal charging car track 11, the exit of the vertical fire channel 8 located in the temperature measuring track 1 is the standard temperature measuring hole 7; the brush-type communication head 3 is located above the ring-shaped temperature measuring track, and the brush-type communication head 3. It is connected with the upper computer 6 installed in the coke oven operating room through the communication line 4; the automatic temperature measurement device 2 is equipped with a computer and an optical probe, and can automatically walk on the temperature measurement track 1 through an external mains power supply for t...

Embodiment 2

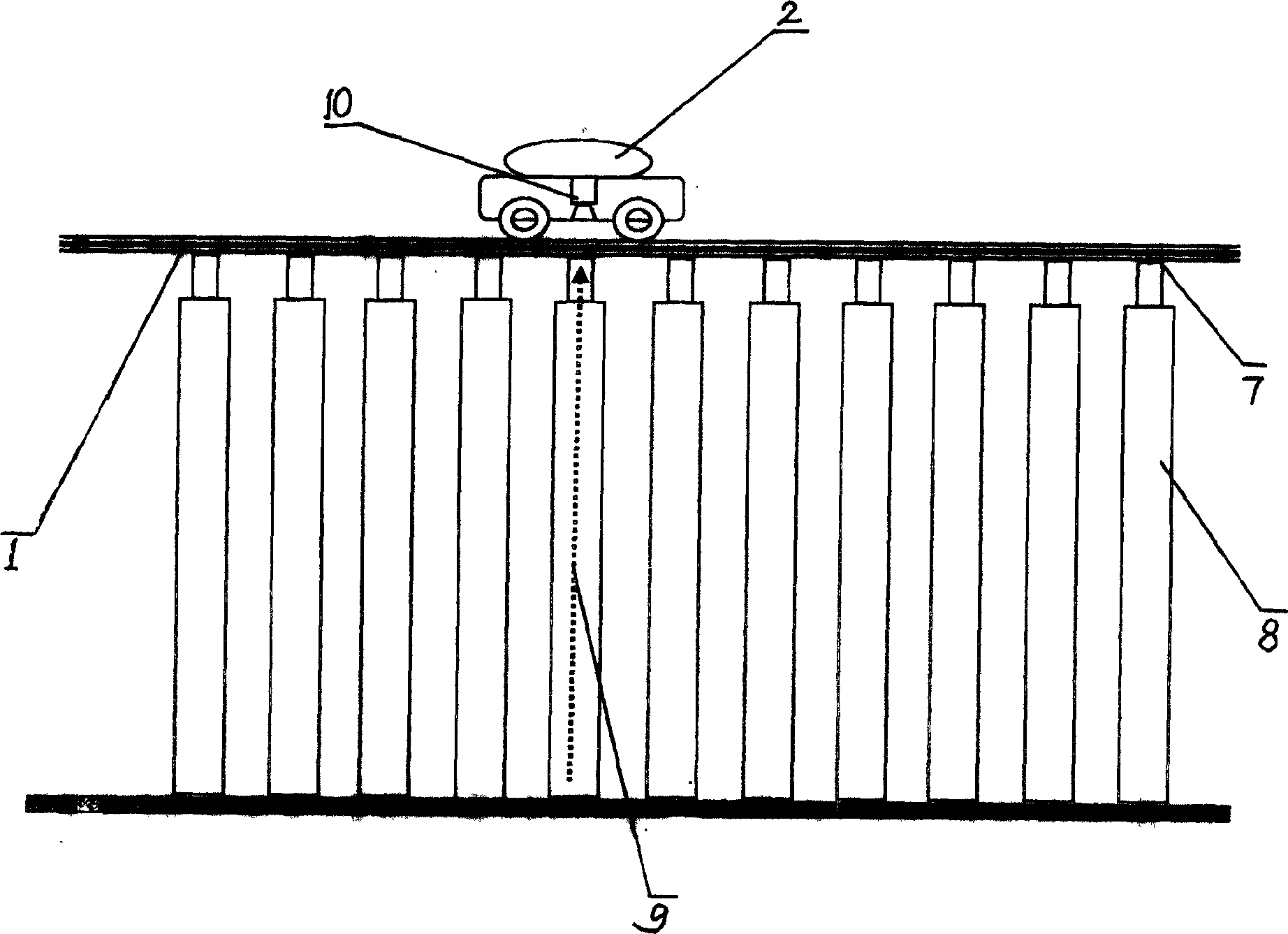

[0026] Embodiment 2: as figure 1 , 2 , 3, 4, 6, 7, 8, 9, 10, 11 and 12, a coke oven automatic temperature measurement system consists of a temperature measurement track 1, an automatic temperature measurement vehicle 2, a brush type communication head 3 and The upper computer is composed of 6, and the brush type communication head is connected with the upper computer through the communication line 4. The temperature measuring track 1 is a circular track set on the inside of the coal charging car track 11 on the furnace surface of the coke oven 5, and the exit of the vertical fire channel 8 located in the temperature measuring track is the standard temperature measuring hole 7; the brush type communication head 3 is located in the ring temperature measuring Above the track 1; the automatic temperature measuring car 2 is composed of a car body 14 with thermal insulation effect, a computer 23 installed in the car body 14, an optical probe 10, a drive unit and a power supply 22 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com