Liquid crystal display panel

A liquid crystal display panel, liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

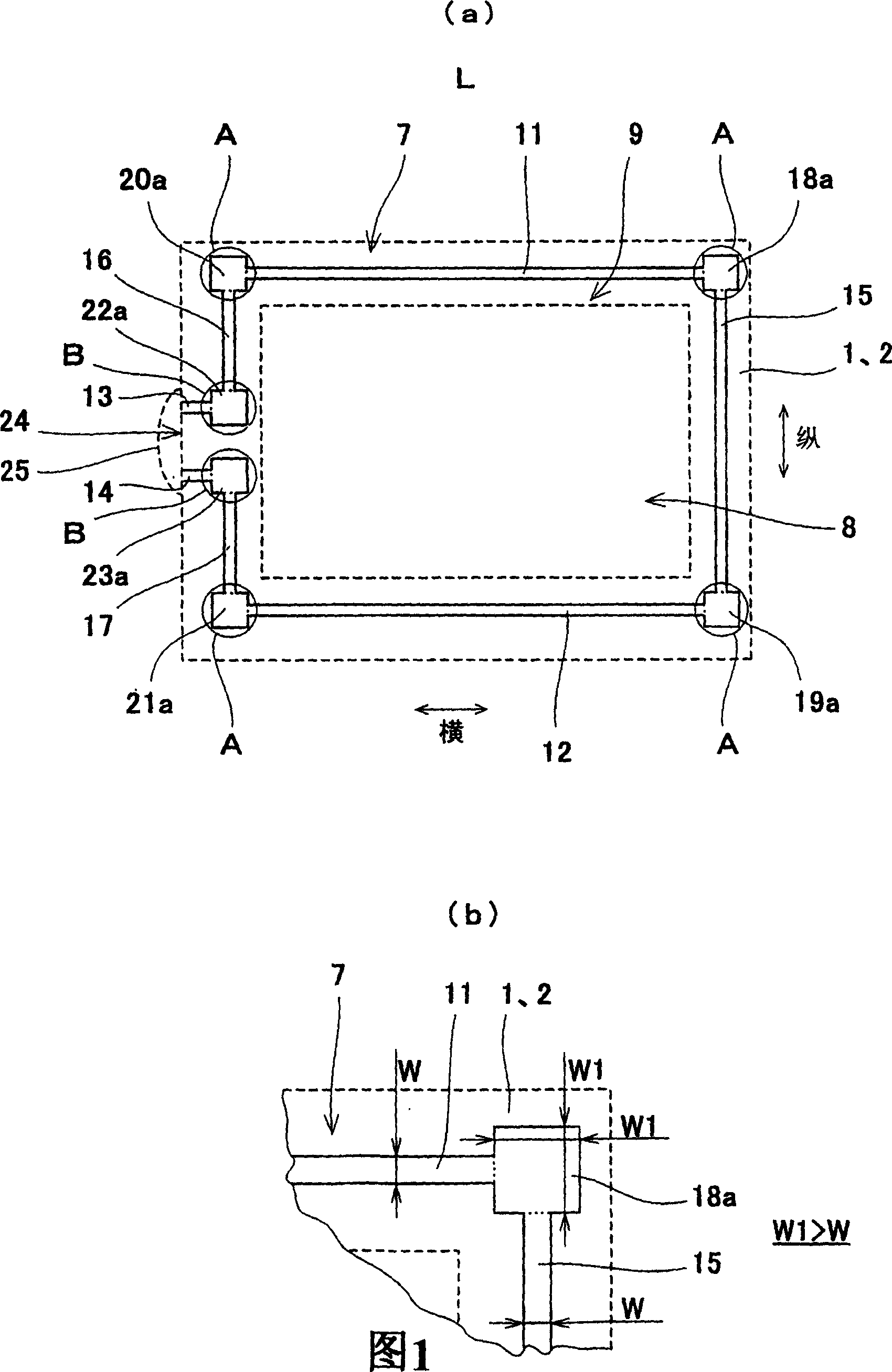

[0029] The first embodiment of the present invention shows a first configuration example of a liquid crystal display panel in which the outflow of a liquid crystal material can be prevented by making the pattern width of the corner pattern wider than that of other patterns other than the corner pattern.

[0030] 1( a ) and FIG. 1( b ) are diagrams schematically showing the shape of a seal pattern for liquid crystal sealing according to the first embodiment of the present invention. Overall plan view of the pattern; FIG. 1( b ) is a plan view enlargedly showing a corner pattern of the seal pattern for liquid crystal sealing in FIG. 1( a ). Here, for convenience of description, the direction of the seal pattern for liquid crystal sealing is shown as shown in the figure. In addition, in Figure 1 with Figure 7 The same reference numerals denote the same or corresponding parts.

[0031] The seal pattern 7 for liquid crystal sealing arranged on the liquid crystal display panel L ...

no. 2 approach

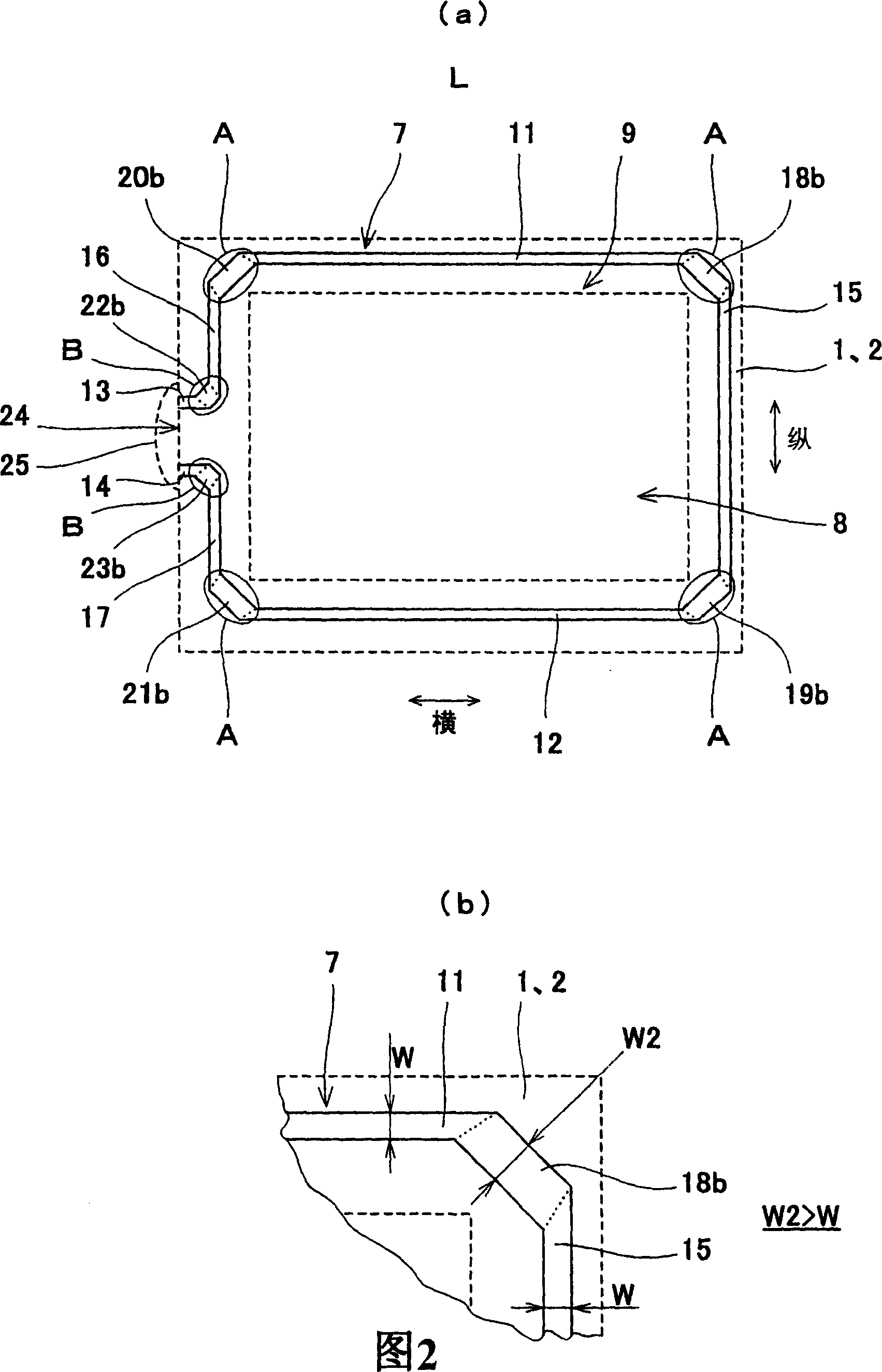

[0039] The second embodiment of the present invention shows a second structural example of a liquid crystal display panel in which the outflow of a liquid crystal material can be prevented by forming the image width of the corner pattern wider than that of other patterns other than the corner pattern.

[0040] Fig. 2 (a) and Fig. 2 (b) are the figures that schematically show the shape of the seal pattern for liquid crystal sealing of the second embodiment of the present invention; The plan view of the whole pattern; FIG. 2( b ) is a plan view enlargedly showing the corner pattern of the seal pattern for liquid crystal sealing in FIG. 2( a ). In addition, in Figure 2 with Figure 7 The same reference numerals denote the same or corresponding parts.

[0041] As shown in FIG. 2(a) and FIG. 2(b), in this embodiment, the pattern width W2 of the corner patterns 18b to 21b and 22b to 23b of the seal pattern 7 for liquid crystal sealing is formed to be wider than that of the corner p...

no. 3 approach

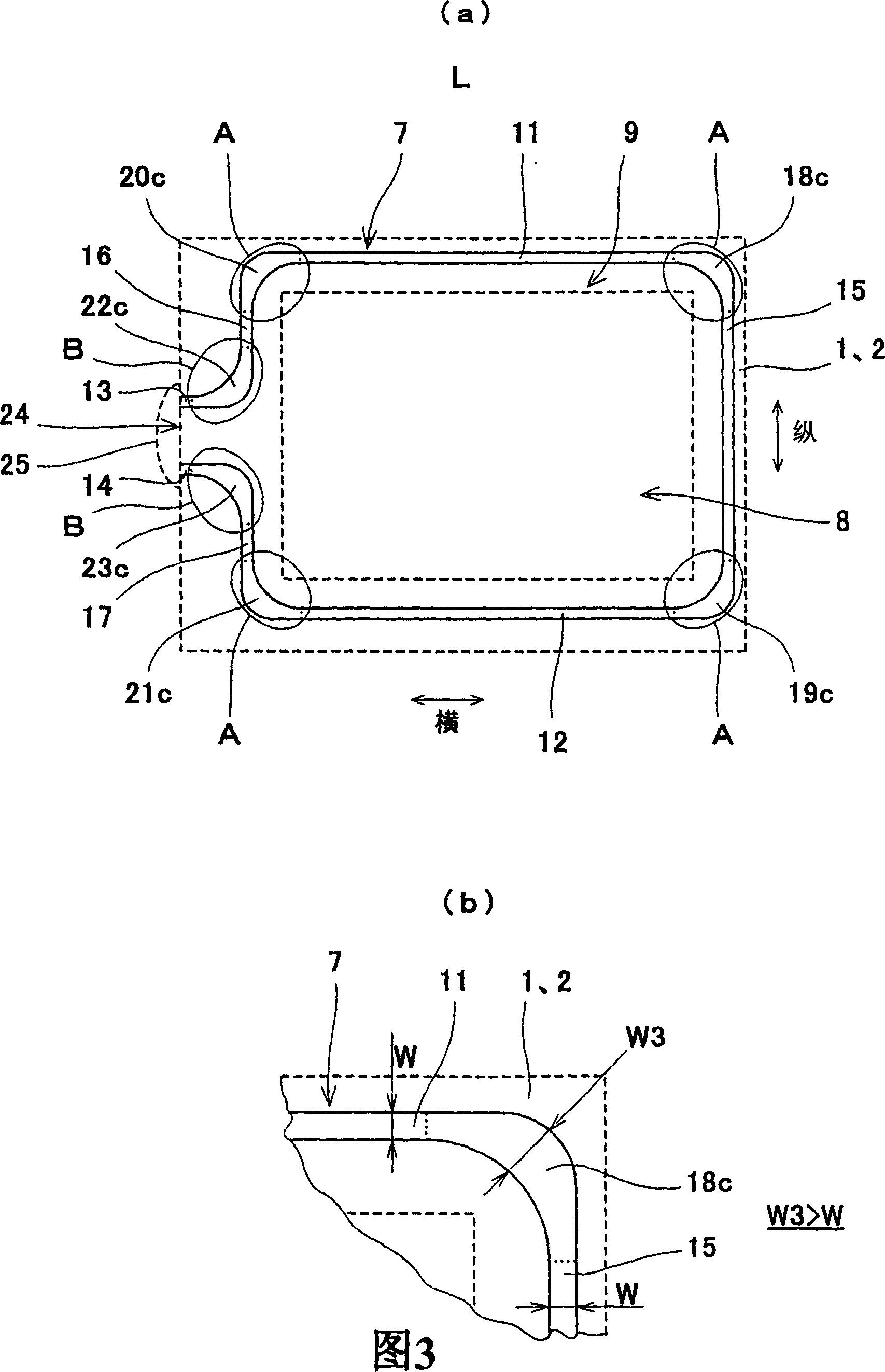

[0045] The third embodiment of the present invention shows a third structural example of a liquid crystal display panel in which the outflow of a liquid crystal material can be prevented by forming the pattern width of the corner pattern wider than that of other patterns other than the corner pattern.

[0046] Fig. 3 (a) and Fig. 3 (b) are the figures that schematically show the shape of the seal pattern for liquid crystal sealing of the third embodiment of the present invention; The plan view of the whole pattern; FIG. 3( b ) is a plan view enlargedly showing the corner pattern of the seal pattern for liquid crystal sealing in FIG. 3( a ). In addition, in Figure 3 with Figure 7 The same reference numerals denote the same or corresponding parts.

[0047] As shown in FIG. 3( a ) and FIG. 3( b ), in this embodiment, the corner patterns 18c to 21c and 22c to 23c of the seal pattern 7 for liquid crystal sealing are formed such that the pattern width W3 at the center is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com