X-ray mask and quartz ring ultraviolet solidifying apparatus and method for using

A curing device and X-ray technology, applied in the direction of photomechanical processing of originals, instruments, patterned surfaces, etc., can solve problems affecting the positioning accuracy of X-ray masks, and achieve simple structure and convenient operation , the effect of short bonding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

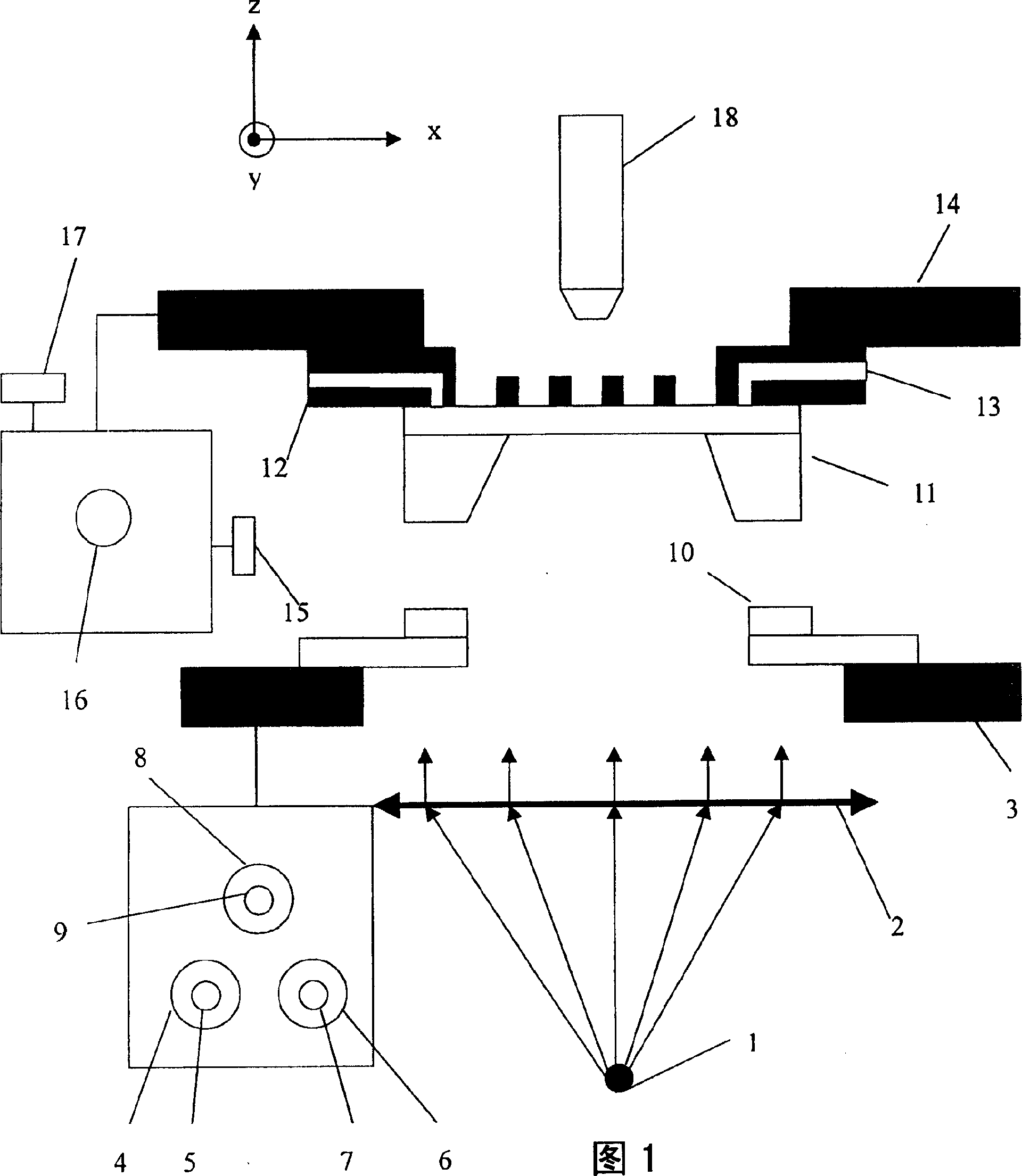

[0029] First please refer to shown in Fig. 1, a kind of X-ray mask and quartz ring ultraviolet curing device of the present invention, comprise:

[0030] An X-ray mask workbench 14, which includes an X-direction displacement handwheel 15, a Y-direction displacement handwheel 16, and a Z-axis rotation handwheel 17 mounted thereon; a vacuum fixture 12 is located on the X-ray mask Below the workbench 14, the vacuum fixture 12 vacuum-adsorbs the X-ray mask 11 through the pipeline 13. The X-ray mask workbench 14 is mainly used to place the X-ray mask 11 to be cured by ultraviolet light, wherein the vacuum fixture 12 passes through the pipeline 13 To vacuum the non-pattern area around the edge of the X-ray mask 11;

[0031] A quartz ring workbench 3, the workbench 3 includes X direction coarse displacement handwheel 4, X direction fine displacement handwheel 5, Y direction coarse displacement handwheel 6, Y direction fine displacement handwheel installed thereon Wheel 7, coarse dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com