Inkjet printer and cap unit for maintenance unit of inkjet printer

An inkjet printer, inkjet technology, applied in printing, etc., can solve the problems of printer size increase, pump failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Next, embodiments of the present invention will be described by way of examples.

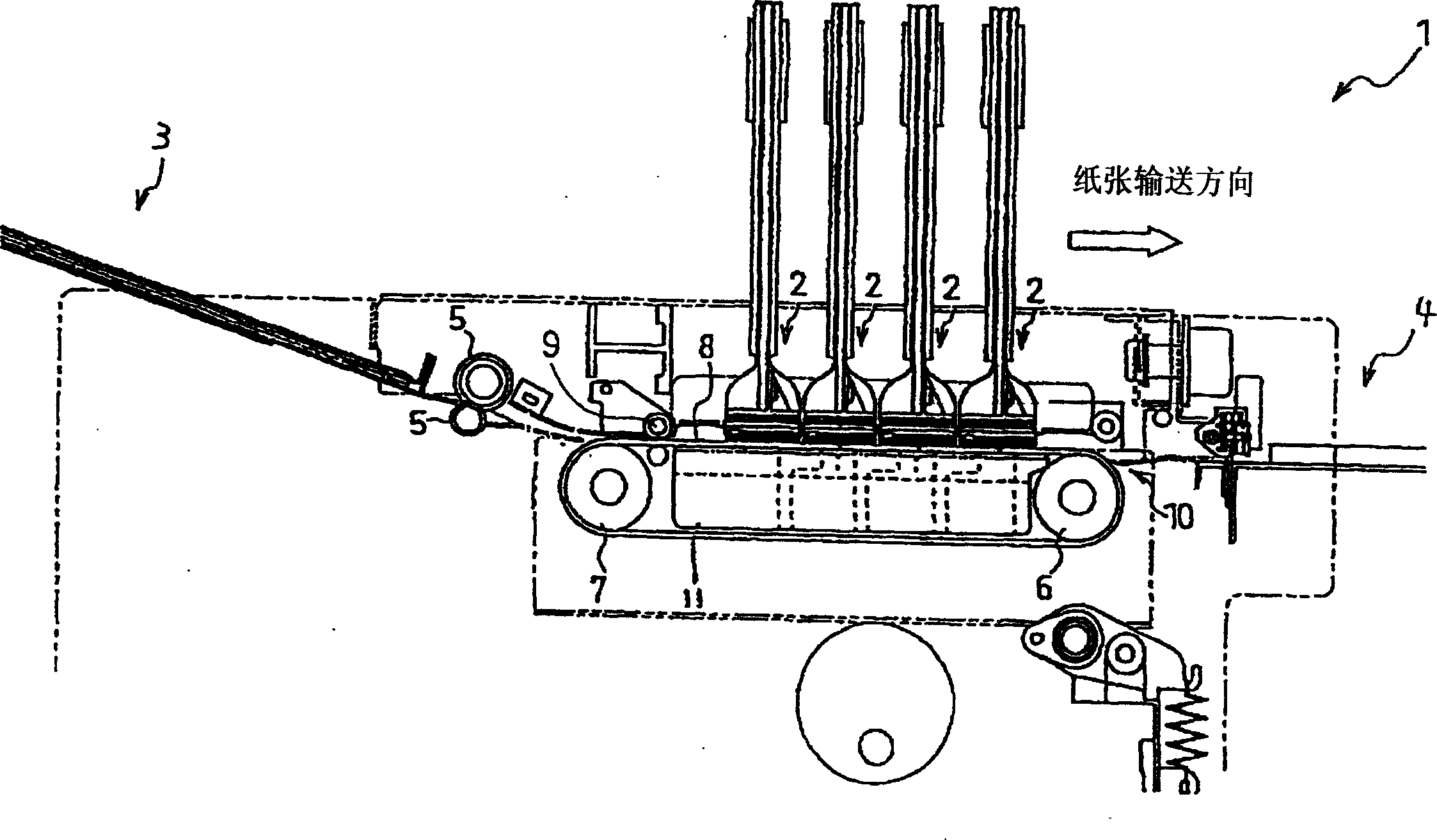

[0044] figure 1 It is a schematic structural diagram of the internal structure of an inkjet printer according to an embodiment of the present invention, shown by way of example and viewed from the left.

[0045] The inkjet printer 1 is a color inkjet printer, and four inkjet heads 2 respectively corresponding to inks of four colors (magenta, yellow, cyan and black) are arranged inside. In addition, this inkjet printer 1 is configured so that it is located on the back side (on the figure 1 The paper feeding section 3 on the left side in ) feeds a paper-like recording medium such as recording paper or various films (hereinafter also referred to as "paper") to the front (in figure 1 Exit section 4 on the right in ). The inkjet printer 1 is internally provided with a pair of pickup rollers 5, two belt rollers 6 and 7, a conveyance belt 8, a pressing member 9, a separating unit 10, a guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com