Dynamic wholly vulcanized thermoplastic rubber one-step production process and apparatus

A thermoplastic rubber and production process technology, applied in the field of polymer materials, can solve the problems of large fluctuations in product performance, low product yield, and low yield, and achieve the effects of improving the working environment, stable quality, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

[0024] The production process of the present invention is continuously carried out from feeding to the completion of full dynamic vulcanization and pelletizing. The length of time and the size of the output of the material in the reaction process in the equipment of the present invention are mainly realized by controlling the amount of feeding and adjusting the rotating speed of the screw.

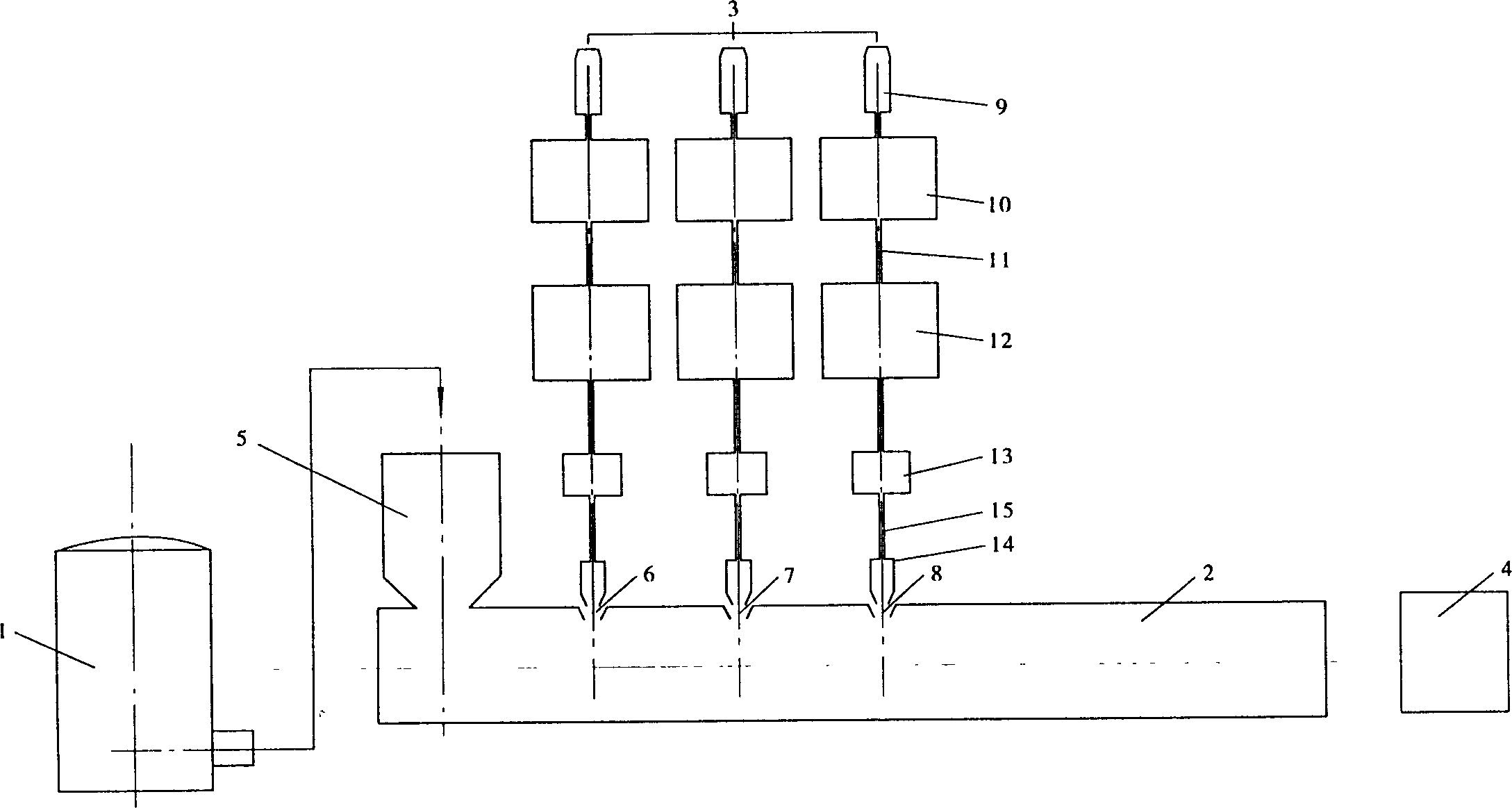

[0025] Now illustrate the present invention in conjunction with accompanying drawing of equipment:

[0026] Take the main material EPDM 43%, PP 18.5%, stir in the high-speed mixer (1) for 3 minutes at high speed, add it into the dynamic melt-mixing vulcanization reactor through the main material feeding cylinder (5), and then press paraffin oil 29.5%, paraffin oil + DCP 9% ratio to take the material, respectively add the agitator (9) of the vulcanization aid injection device (3), heat the upper tank (10) to 100 °C through the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com