Elastomer composition and rubber roller

A composition and elastomer technology, applied in the fields of elastomer compositions and rubber rollers, can solve the problems of inability to combine well and improve tensile strength

Inactive Publication Date: 2005-02-02

SUMITOMO RUBBER IND LTD

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Also, since the resin component and the rubber component are not well bonded to each other, it cannot be expected to increase in tensile strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~6

[0076] The rubber component (A), the mixture composition (B), and the styrene thermoplastic elastomer composition (C) were mixed in the proportions shown in Table 1. That is: the styrene thermoplastic elastomer (C) is mixed in a ratio of not less than 2 parts by weight and not more than 100 parts by weight with respect to 200 parts by weight of the mixture composition (B). EPDM was used as the rubber component.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

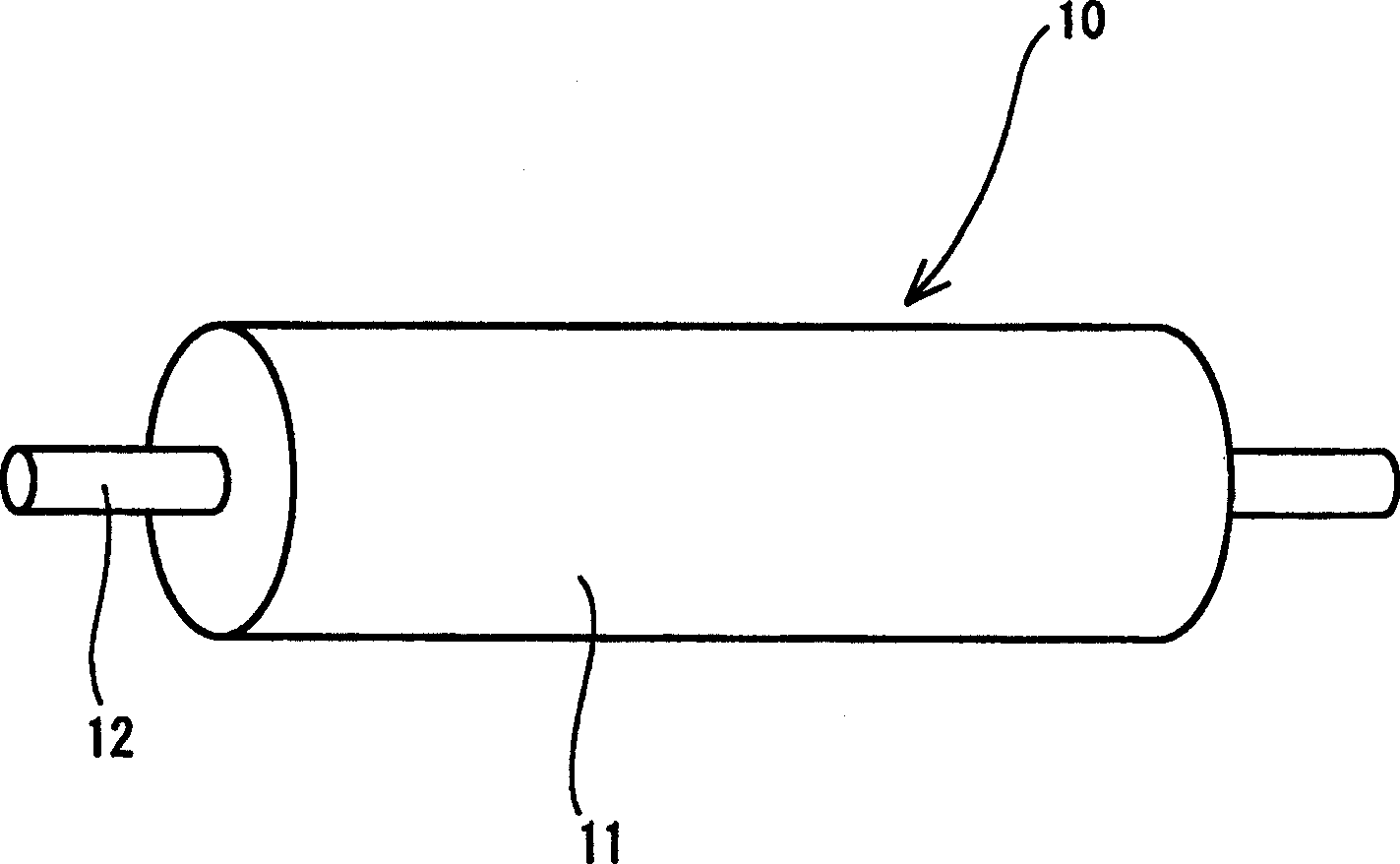

An elastomer composition is prepared that contains a rubber component (A) containing at least one of diene rubber and EPDM rubber; a mixture composition (B) containing hydrogenated styrene thermoplastic elastomer and olefin resin; and a styrene thermoplastic elastomer (C) having double bonds partly left, wherein the styrene thermoplastic elastomer (C) is blended at a ratio of not less than 2 parts by weight and not more than 100 parts by weight with respect to 200 parts by weight of the mixture composition (B), and the rubber component (A) is dispersed by dynamic crosslinking in the mixture composition (B) having the styrene thermoplastic elastomer (C) dispersed therein. A rubber roller is formed by using the elastomer composition. The elastomer composition is excellent in wear resistance, and the rubber roller made of the elastomer composition is excellent in wear resistance at the time of idling rotation.

Description

technical field [0001] The present invention relates to an elastomer composition and a rubber roller formed using the elastomer composition. More particularly, the present invention relates to an elastomer composition having extremely excellent abrasion resistance while having appropriate hardness, which is suitable for use in OA equipment such as inkjet printers, laser printers, xerographic copiers, or facsimile The rubber roller in the paper feeding device of machine, automatic teller machine etc., also relates to its preparation method simultaneously. Background technique [0002] The paper feeding rubber roller made of rubber composition, elastomer composition or similar composition is used in the paper feeding device of OA equipment such as: inkjet printer, laser printer, electrostatic copier or fax machine, automatic teller machine (ATM), etc. Used to convey paper, film, etc. [0003] In recent years, OA apparatuses for private use have dramatically increased in numb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16C13/00C08L9/00C08L9/06C08L21/00C08L23/00C08L23/16C08L23/22C08L53/00C08L53/02D21F1/40

CPCC08L53/02C08L23/16C08L21/00C08L53/025C08L23/22C08L2312/00C08L2666/24C08L2666/02C08L2666/04A45D8/02A45D8/36A44B18/00A45D8/26A45D8/002A45D8/004

Inventor 杉本睦树奥山英之

Owner SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com