Micro actuator for controlling focal depth

A microcontroller, depth of focus technology, applied in instrumentation, head configuration/installation, optics, etc., which can solve problems such as power consumption, inability to achieve compact size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described in detail by way of examples illustrated in the accompanying drawings.

[0028] There are many possible embodiments for a microcontroller for controlling the depth of focus according to the present invention, the preferred embodiment will now be described.

[0029] The scope of the invention is not limited to the specific embodiments described below but can vary within the scope of the claims.

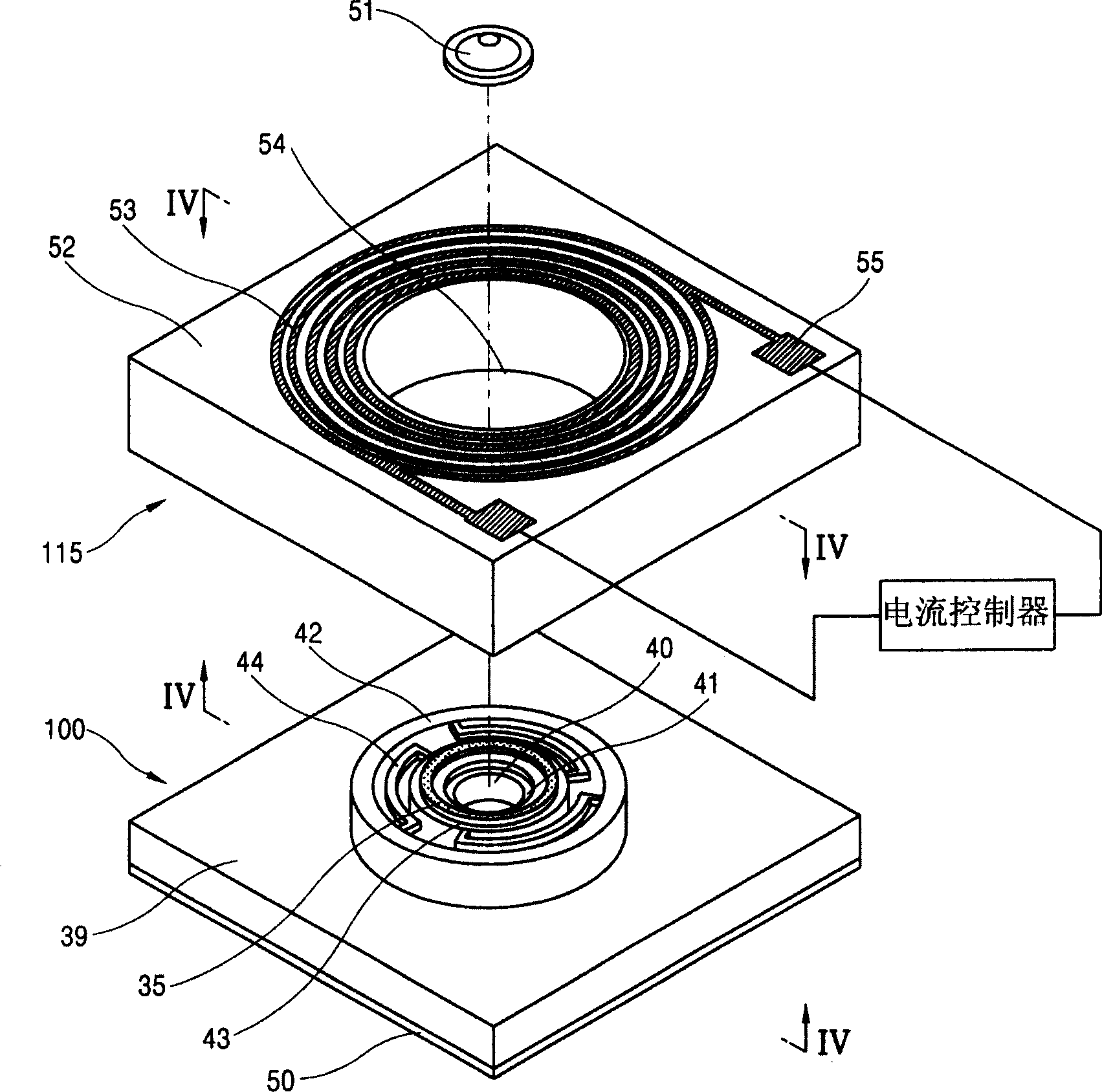

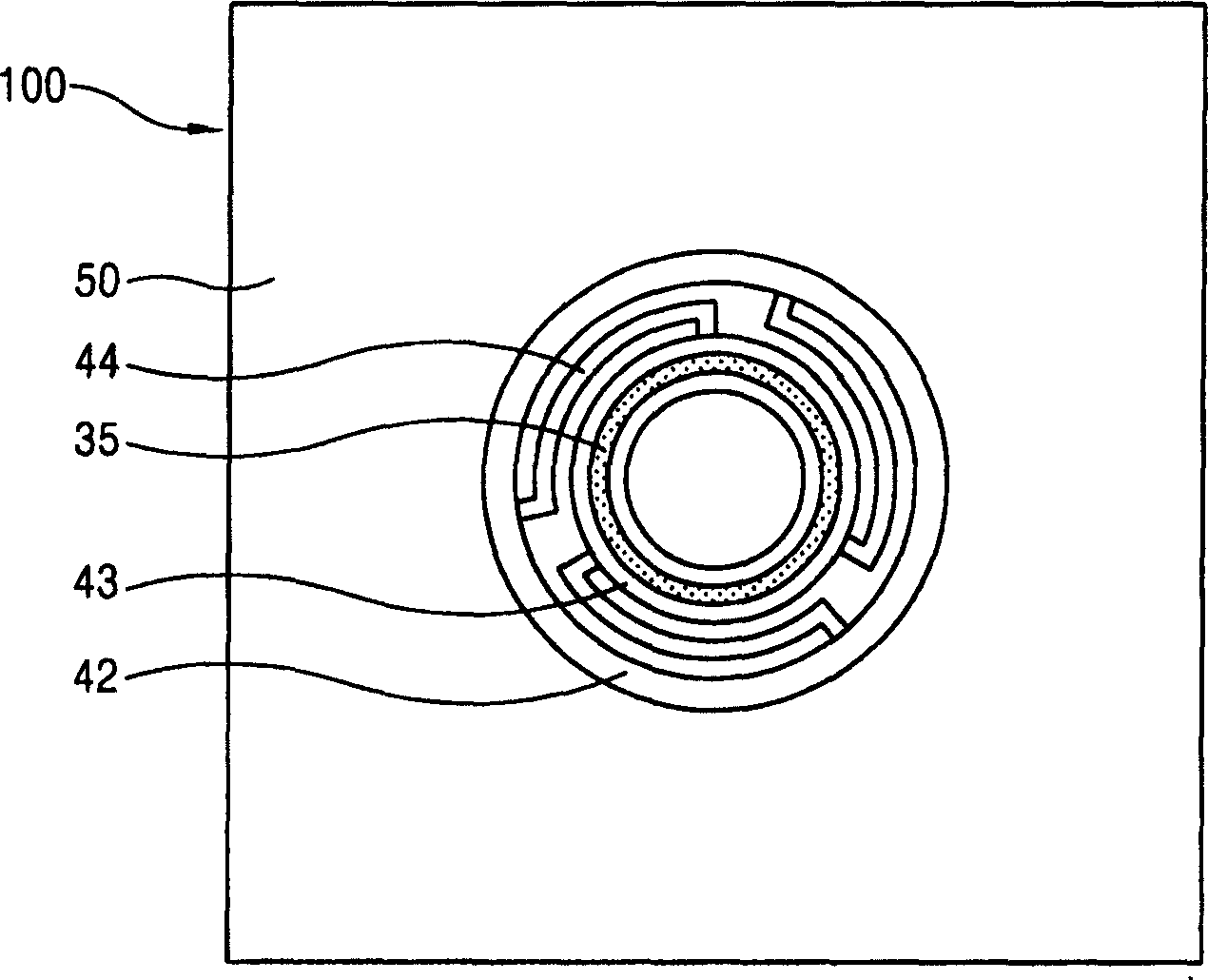

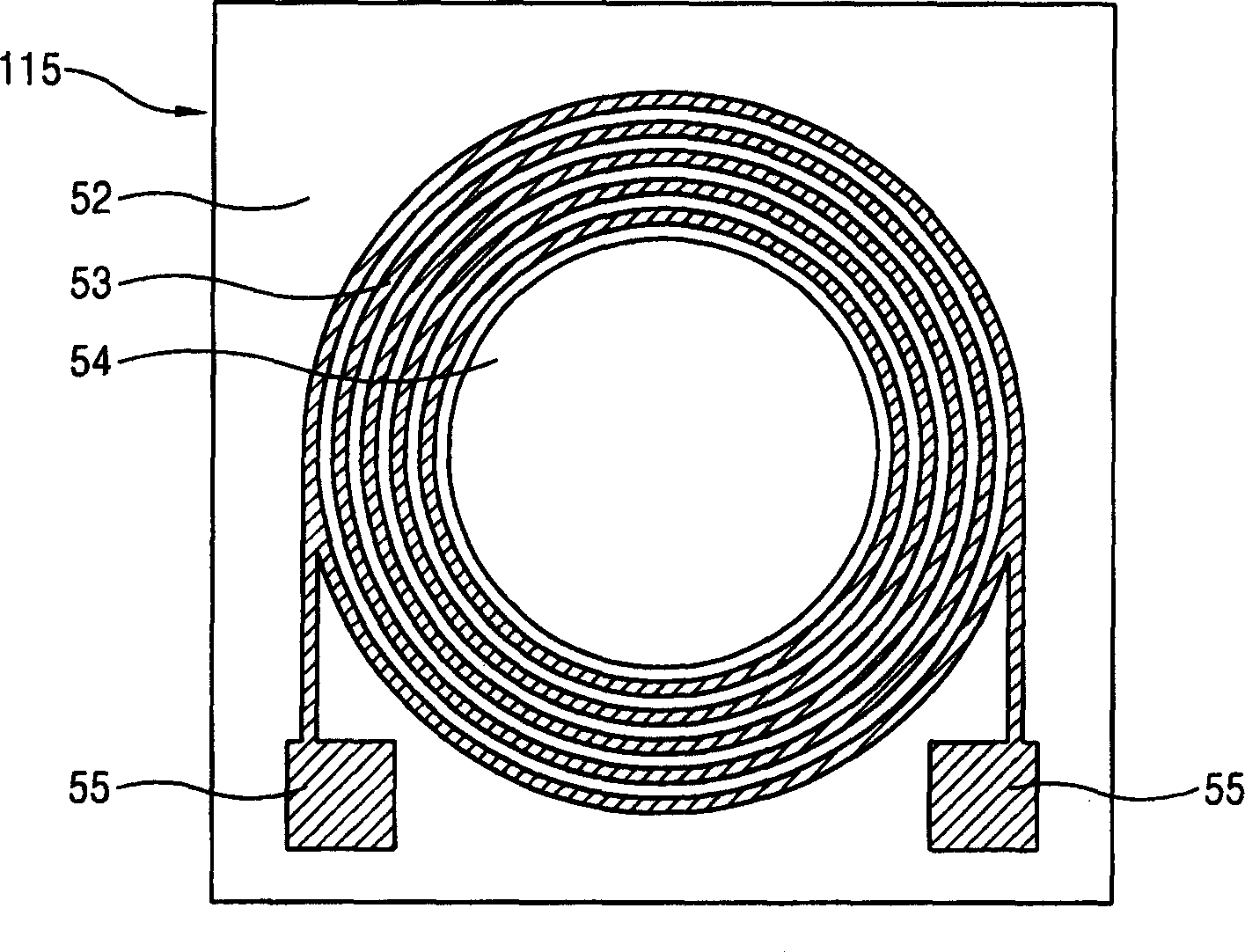

[0030] Figures 1 to 4 A microcontroller for controlling the depth of focus according to the first embodiment of the present invention will be described. in detail, figure 1 is a partially exploded schematic diagram illustrating a lens mounting part and a laminated coil for a microcontroller for controlling a depth of focus according to a first embodiment of the present invention, figure 2 is a plan view illustrating a lens mounting part according to a first embodiment of the present invention, image 3 is a plan v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com