Steel for plastic injection moulding die with excellent mechanical workability

An injection molding and machining technology used in the field of steel for plastic injection molding molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

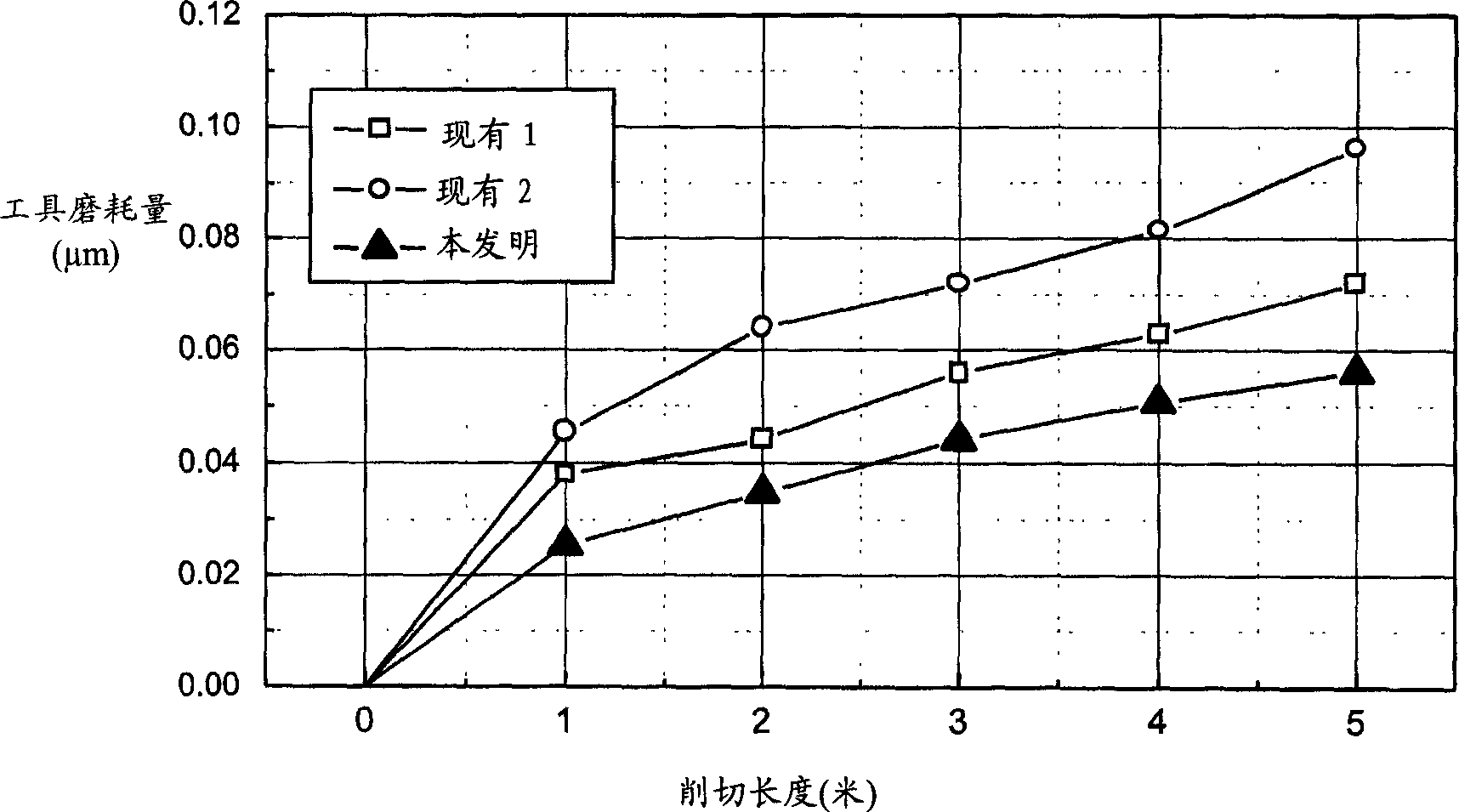

[0029] In order to compare the characteristics of the SCM4 series and the improved SNCM4 series of mold steels that have been widely used as materials for plastic injection molding molds, and the mold steels of the present invention, these mold steels were produced by the production process described below.

[0030] First, a steel material having an alloy composition described in Table 1 was melted in an electric furnace, refined in a vacuum refining furnace, and a 25-ton ingot was cast. Then, the steel block was heated at 1170° C. and forged at a forging ratio of 4 or greater to produce an angle bar with a width of 1200 mm and a thickness of 430 mm. At this time, the temperature at the end of forging was 850° C., and normalization treatment was performed by heating at 880° C. after the end of forging.

[0031] In order to provide the same cooling conditions during quenching, the heat treatment of quenching and tempering is performed in the state where the forging scale is rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com