Vacuum forming and injection molding composite board of supersonic welding

A technology of ultrasonic welding and composite board, which is applied in the direction of sheets/boards, building components, etc., can solve the problems of heavy plastic boards, insufficient strength of composite boards, and difficult fabrication of board surfaces, achieving good flatness, widening the scope of use, Effects of various colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

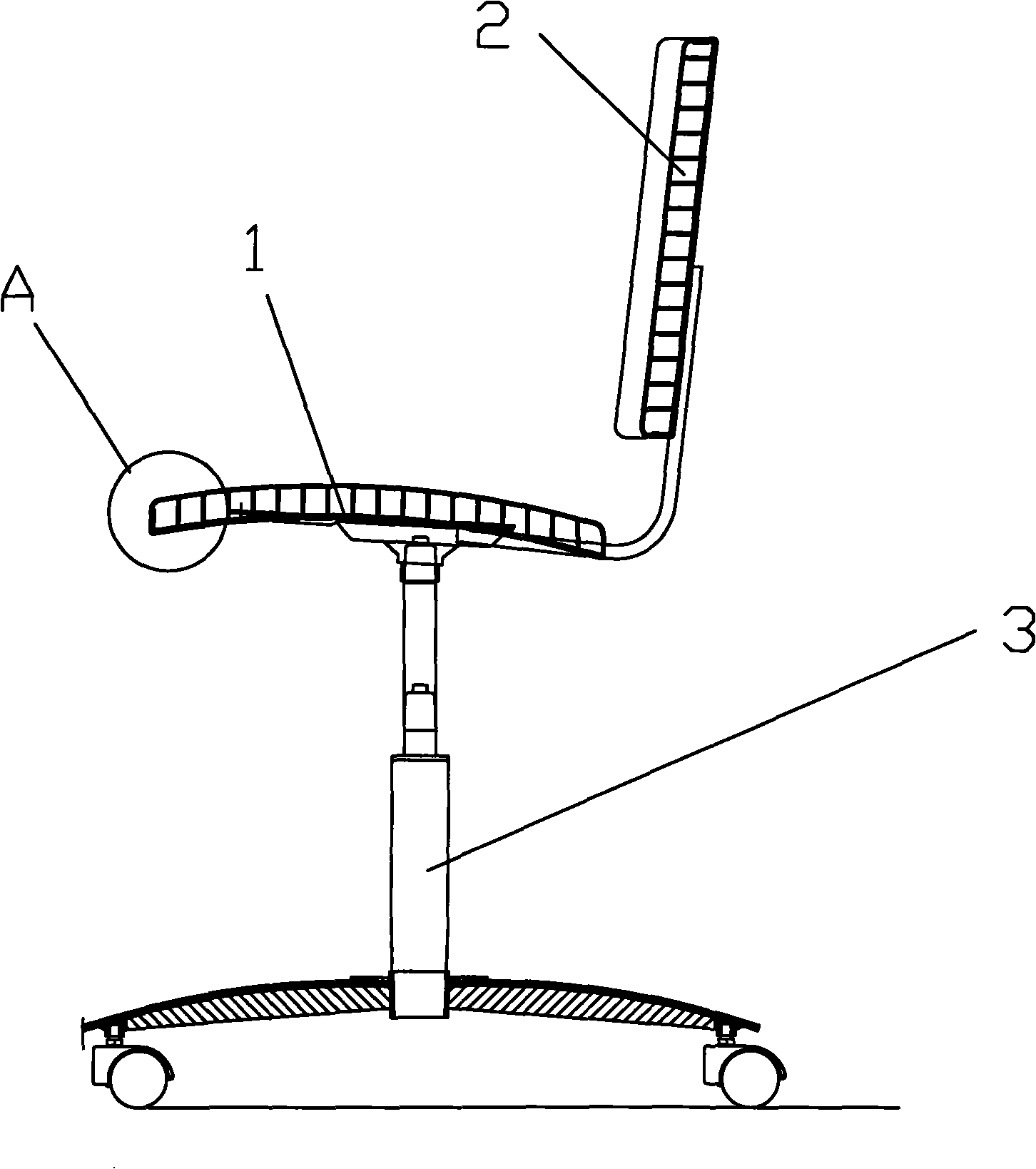

[0053] Embodiment one, see figure 1 As shown in Figure 7, an ultrasonically welded plastic-absorbing injection-molding composite board of the present invention is used on a seat, figure 1 A schematic diagram of the structure of a seat is given. The seat includes a chair frame 3, a chair panel 1 and a chair back 2 mounted on the chair frame 3. Both the chair panel 1 and the chair back 2 are plastic injection molded by ultrasonic welding. Blister composite board.

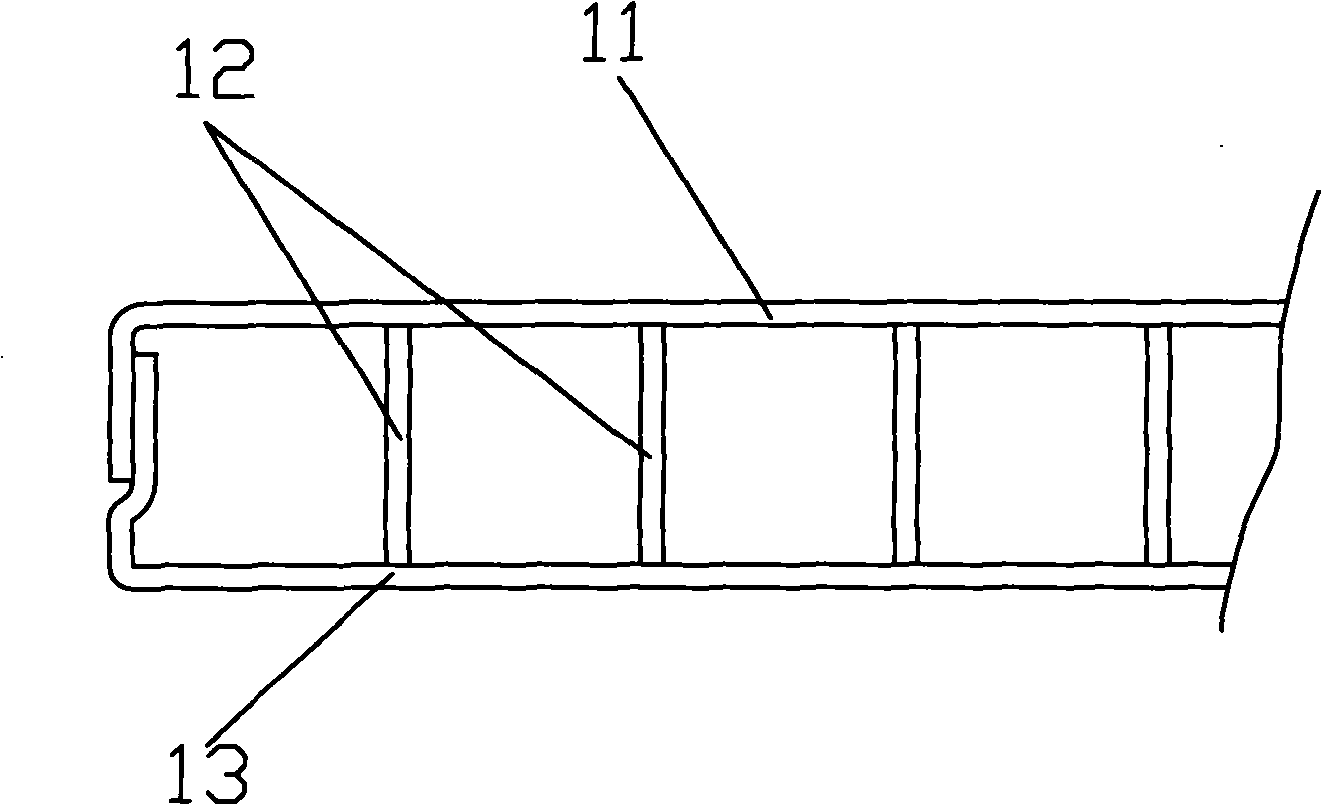

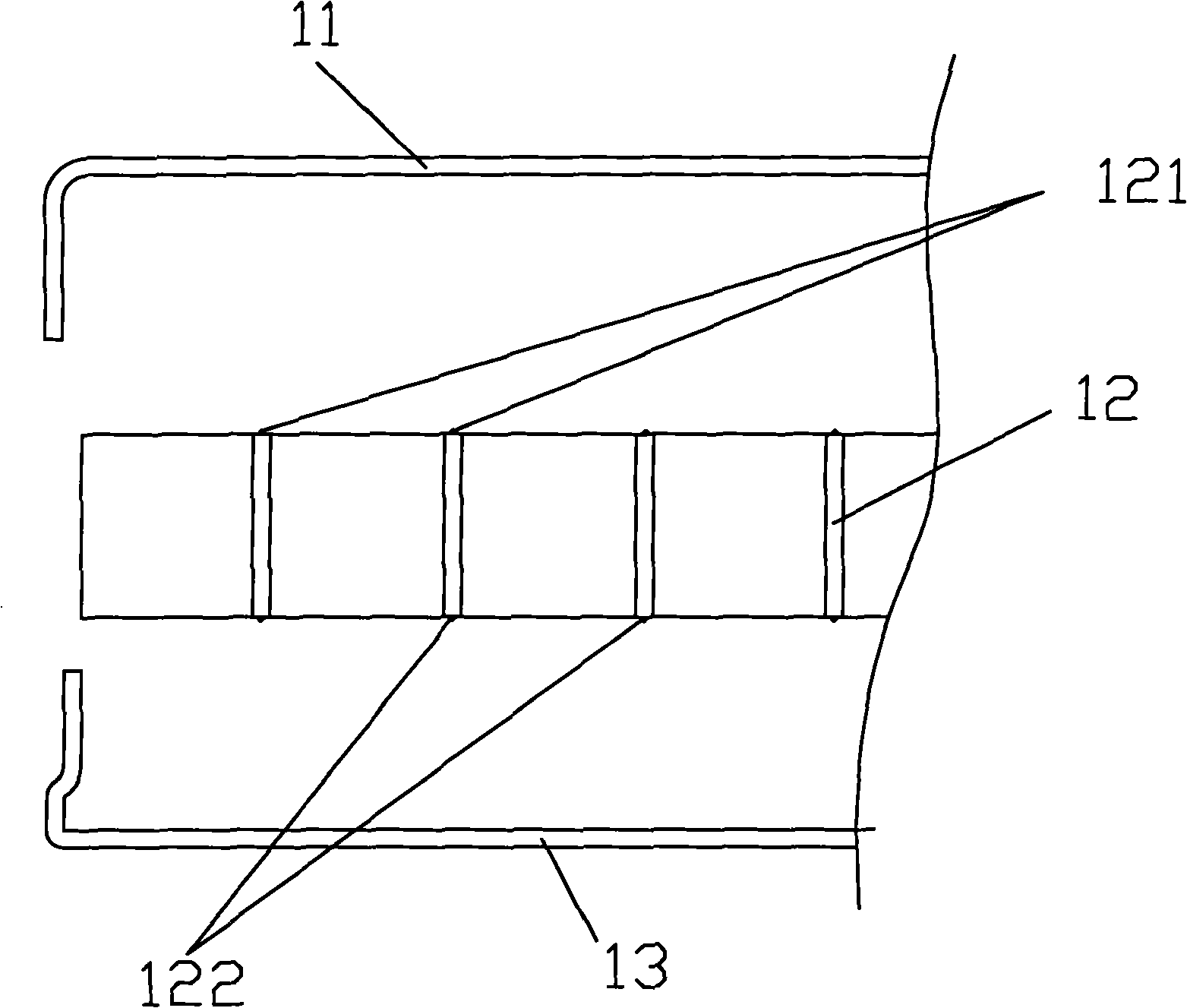

[0054] Such as Figure 2 to Figure 5 As shown, the chair board 1 includes:

[0055] The plastic panel 11 is a monomer structure with a certain shape made by direct extrusion molding or extrusion molding, and has an upper surface and an inner surface;

[0056] The plastic bottom plate 13 is a monomer structure with a certain shape made by direct extrusion molding or extrusion molding, and has an inner surface and a lower surface;

[0057] The injection molded part 12 is a single structural part made by direct injec...

Embodiment 2

[0065] Embodiment two, see Figure 8 As shown, an ultrasonically welded plastic-absorbing plastic-absorbing composite board of the present invention is used on a seat. The difference from Embodiment 1 is that the surface of the panel is provided with a printing layer 112, which is made The printing method directly prints the texture or pattern structure on the surface of the panel. For example, the upper surface of the panel 11 can be printed to produce various colors of natural materials such as wood grain and marble. The upper surface of the plastic panel can also be provided with textures or pattern structures produced by the transfer film. For example, the surface of the panel can be compounded with a transfer film with various wood grains, marble and other natural material colors. Remove the film and spray heat-cured or light-cured varnish to increase the hardness and weather resistance of the surface.

Embodiment 3

[0066] Embodiment three, see Figure 9 to Figure 1 As shown in 0, a kind of ultrasonically welded plastic-absorbing injection-molding composite board of the present invention is used on a seat, Figure 9 A schematic diagram of the structure of another structural seat is given. The seat includes a chair frame 30, a seat board 10 mounted on the chair frame 30, and a chair back 20. Both the chair board 10 and the chair back 20 are ultrasonically welded. Plastic injection molding composite board.

[0067] Among them, the chair board 10 includes a plastic panel 15, a plastic bottom plate 18, an injection molded part 16 and an embedded reinforcement 17; The single structure of the single body; the injection molded part 16 is two monomers, which are respectively located on both sides of the chair board, and the upper and lower parts of the injection molded part 16 are integrally injection molded with ribs or bumps (not shown), and the plastic panel 15 1. When the plastic bottom pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com